Biosurfactant for oil reduction of oil sludge

A technology of biological active agent and non-ionic active agent, applied in the field of compound biological active agent, can solve the problems of low elution efficiency, high configuration cost, difficult configuration, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

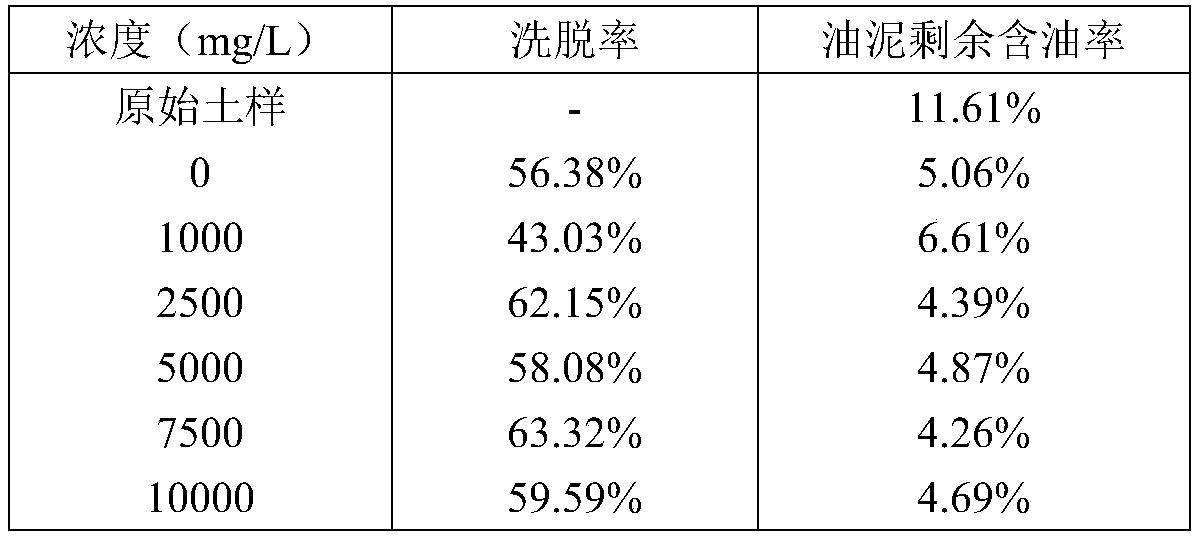

[0007] Example experiment 1:

[0008] Take 5g of Xinjiang oil sludge, air-dry, remove large impurities, crush, and sieve

[0009] Weigh 34.00mg of saponin, 5.00mg of rhamnolipid and 240mg of carboxamide with a precision balance according to the weight ratio, and mix the powder and liquid into a clean beaker.

[0010] Add 111.6ml of distilled water and stir thoroughly with a clean glass rod.

[0011] Obtain the finished product, obtain 20g reagent with precision balance.

[0012] Mix the treated sludge and reagents, stir evenly, and put them into a conical flask.

[0013] Place the Erlenmeyer flask in a water bath at 60°C, adjust the stirring speed to 100r / min, set the heat washing time to 30min, then take it out and let it stand still.

[0014] After standing still, the sample was centrifuged in a centrifuge at a speed of 5000r / min for 10 minutes to realize the three-phase separation of oil, liquid and solid.

[0015] Take out the solid matter and let it dry naturally in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com