Low-carbon magnesia carbon brick with addition of titanium carbonitride and preparation method thereof

A carbon magnesia carbon brick and titanium carbonitride technology, applied in the field of refractory materials, can solve the problems of aggravating the erosion of refractory materials, increasing the tapping temperature, consuming large graphite sources, etc. The effect of good furnace protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

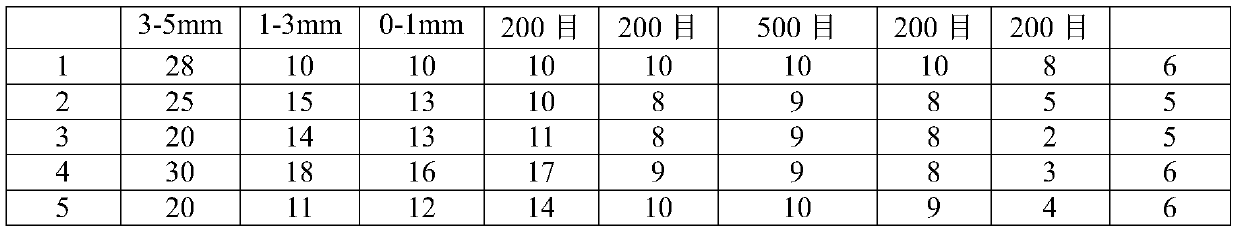

[0025] The present invention will be described in detail below, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

[0026] Low-carbon magnesia-carbon bricks with titanium carbonitride added, including the following raw materials by weight:

[0027] The particle size is 3mm

[0028] The particle size is 1mm

[0029] The particle size is 0mm

[0030] 10-20 parts of 200 mesh fused magnesia;

[0031] 1-10 parts of Ti(C,N) powder synthesized from 200 mesh; The synthesized Ti(C,N) powder is made by mixing titanium carbide and titanium nitride powder in a ratio of 1:1;

[0032] 1-10 parts of 200 mesh graphite;

[0033] 1-10 parts of 200 mesh carbon black;

[0034] 1-10 parts of 200 mesh aluminum powder;

[0035] The binding agent is 1-10 parts; the binding agent is phenolic resin.

[0036] In the above formula, fused magnesia, gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com