High-strength, high-toughness and heat-resistant aluminum alloy material for internal combustion engine and preparation method of aluminum alloy material

An aluminum alloy material, high-strength and toughness technology, which is applied in the field of high-strength, toughness and heat-resistant aluminum alloy materials for internal combustion engines and its preparation field, can solve the problems of poor creep resistance and fatigue properties at high temperature, coarse structure of aluminum alloy materials, and less high temperature strengthening. , to achieve the effect of good thermal fatigue resistance, uniform structure distribution, and improved high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

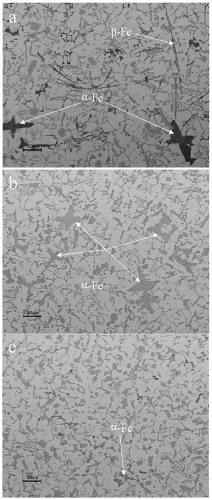

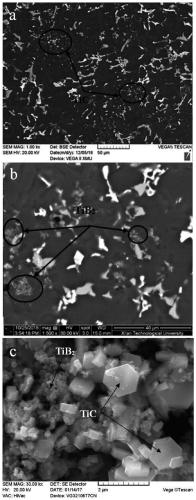

Image

Examples

Embodiment 1

[0036] A high-strength and heat-resistant aluminum alloy material for internal combustion engines, specifically composed of the following elements in weight percentage: Si: 17.0wt%, Cu: 2.0wt%, Ni: 1.5wt%, Mg: 0.6wt%, Fe: 0.4 wt%, Cr: 0.4wt%, Zr: 0.3wt%, Ti: 0.3wt%, Sc: 0.3wt%, B: 0.15wt%, C: 0.1wt%, P: 0.08wt%, RE: 0.4 wt%, the balance is Al.

[0037] A method for preparing the above-mentioned high-strength, toughness and heat-resistant aluminum alloy material for internal combustion engines, specifically comprising the following steps:

[0038]S1. Potassium fluoroborate, potassium fluorotitanate, and sodium fluoroaluminate were mixed according to a weight ratio of 8:8:1, followed by vacuum ball milling for 1 hour, and then placed in a mold for cold pressing to obtain a compact 1; , titanium powder and aluminum powder are mixed according to the ratio of 1:4:3 by weight, then vacuum ball milled for 8 hours, and then placed in a mold for cold pressing to obtain briquetting 2; ...

Embodiment 2

[0044] A high-strength and heat-resistant aluminum alloy material for internal combustion engines, specifically composed of the following elements in weight percentage: Si: 9.0wt%, Cu: 7.0wt%, Ni: 5.5wt%, Mg: 1.0wt%, Fe: 0.6 wt%, Cr: 0.6wt%, Zr: 0.2wt%, Ti: 0.2wt%, Sc: 0.2wt%, rare earth element RE: 0.5wt%, B: 0.3wt%, C: 0.2wt%, P: 0.1 wt%, the balance is Al.

[0045] A method for preparing the above-mentioned high-strength, toughness and heat-resistant aluminum alloy material for internal combustion engines, specifically comprising the following steps:

[0046] S1. Potassium fluoroborate, potassium fluorotitanate, and sodium fluoroaluminate were mixed according to a weight ratio of 8:8:1, followed by vacuum ball milling for 2 hours, and then placed in a mold for cold pressing to obtain a compact 1; , titanium powder and aluminum powder are mixed according to the ratio of 1:4:3 by weight, then vacuum ball milled for 9 hours, and then placed in a mold for cold pressing to obta...

Embodiment 3

[0052] A high-strength and tough heat-resistant aluminum alloy material for internal combustion engines, specifically composed of the following elements in weight percentage: Si: 13.0wt%, Cu: 4.0wt%, Ni: 3.5wt%, Mg: 1.5wt%, Fe: 1.1 wt%, Cr: 1.1wt%, Zr: 0.1wt%, Ti: 0.1wt%, Sc: 0.1wt%, rare earth element RE: 0.6wt%, B: 0.5wt%, C: 0.3wt%, P: 0.12 wt%, the balance is Al.

[0053] A method for preparing the above-mentioned high-strength, toughness and heat-resistant aluminum alloy material for internal combustion engines, specifically comprising the following steps:

[0054] S1. Potassium fluoroborate, potassium fluorotitanate, and sodium fluoroaluminate were mixed according to a weight ratio of 8:8:1, followed by vacuum ball milling for 3 hours, and then placed in a mold for cold pressing to obtain a briquette 1; carbon powder , titanium powder and aluminum powder are mixed according to the ratio of 1:4:3 by weight, then vacuum ball milled for 10h, and then placed in a mold for c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com