Aluminum alloy for high-speed rail windshield and preparation method thereof

An aluminum alloy and windshield technology, applied in the field of aluminum alloy materials, can solve the problems that aluminum alloy profiles cannot have obvious deformation and structural defects, affect the quality and service life of high-speed rail car windshields, reduce product plasticity, etc., and achieve fine grain size , Welding performance improvement, the effect of ensuring the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

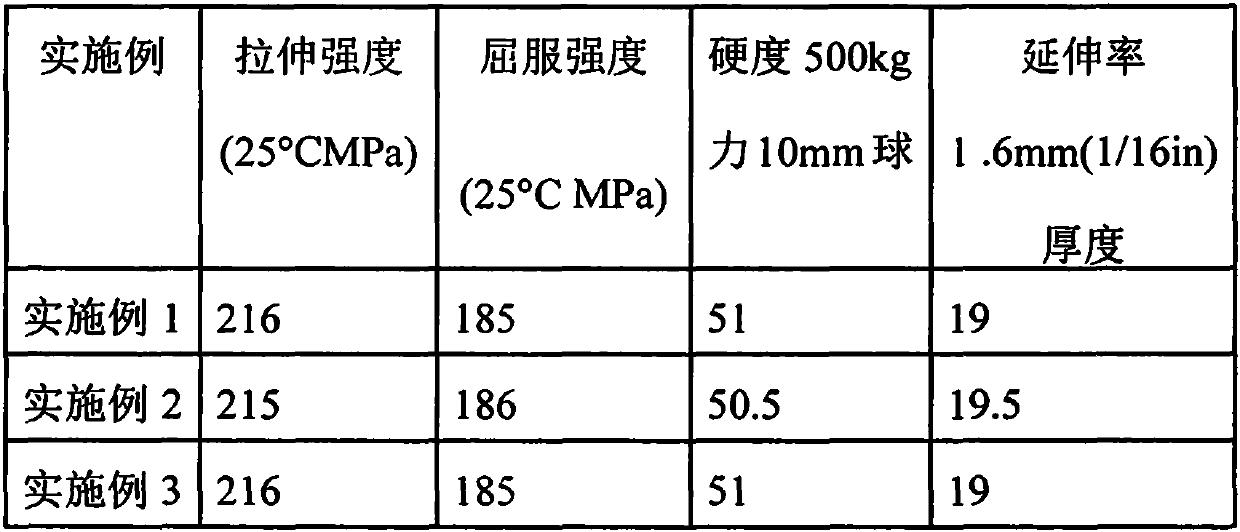

Examples

Embodiment 1

[0019] An aluminum alloy for high-speed rail windshields, which is composed of the following components in weight percentage: 0.48% magnesium, 0.33% silicon, 0.12% iron, 0.06% chromium, 0.06% manganese, 0.02% zinc, and 0.06% copper , titanium ≤ 0.1%, the balance is aluminum and impurities with a content ≤ 0.5%.

[0020] The preparation method is as follows:

[0021] (1) Heat the molten aluminum to 740°C, add magnesium ingots (the mass ratio of magnesium is 99.99%) and aluminum-silicon alloy (the mass ratio of silicon is 20%), mix well, and pass into the refining agent for three times of refining and slag removal , the main components of the refining agent are NaNO3, KF, NaF, etc., and the dosage is 0.32% of the weight of the aluminum liquid;

[0022] (2) Carry out rapid pre-furnace analysis of the components of the molten aluminum, replenish materials, and adjust the content of each component;

[0023] (3) adding aluminum-titanium-boron wire to the aluminum liquid at a unifo...

Embodiment 2

[0029] An aluminum alloy for high-speed rail windshields, which is composed of the following components in weight percentage: 0.53% magnesium, 0.35% silicon, 0.12% iron, 0.1% chromium, 0.06% manganese, 0.02% zinc, and 0.06% copper , titanium ≤ 0.1%, the balance is aluminum and impurities with a content ≤ 0.5%.

[0030] The preparation method is as follows:

[0031] (1) Heat the molten aluminum to 740°C, add magnesium ingots (the mass ratio of magnesium is 99.99%) and aluminum-silicon alloy (the mass ratio of silicon is 20%), mix well, and pass into the refining agent for three times of refining and slag removal , the main components of the refining agent are NaNO3, KF, NaF, etc., and the dosage is 0.32% of the weight of the aluminum liquid;

[0032] (2) Carry out rapid pre-furnace analysis of the components of the molten aluminum, replenish materials, and adjust the content of each component;

[0033] (3) adding aluminum-titanium-boron wire to the aluminum liquid at a unifor...

Embodiment 3

[0039] An aluminum alloy for high-speed rail windshield, which is composed of the following components in weight percentage: 0.50% magnesium, 0.34% silicon, 0.12% iron, 0.08% chromium, 0.06% manganese, 0.02% zinc, 0.06% copper, Titanium≤0.1%, the balance is aluminum and impurities with a content≤0.5%.

[0040] The preparation method is as follows:

[0041] (1) Heat the molten aluminum to 740°C, add magnesium ingots (the mass ratio of magnesium is 99.99%) and aluminum-silicon alloy (the mass ratio of silicon is 20%), mix well, and pass into the refining agent for three times of refining and slag removal , the main components of the refining agent are NaNO3, KF, NaF, etc., and the dosage is 0.32% of the weight of the aluminum liquid;

[0042] (2) Carry out rapid pre-furnace analysis of the components of the molten aluminum, replenish materials, and adjust the content of each component;

[0043] (3) adding aluminum-titanium-boron wire to the aluminum liquid at a uniform speed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com