High-manganese nitrogen-free high-strength and high-toughness anti-hydrogen embrittlement austenitic stainless steel and preparation method thereof

A high-strength, high-toughness, brittle austenite technology is applied in the field of high-strength, high-toughness, hydrogen embrittlement-resistant austenitic stainless steel and its preparation. It can solve problems such as stress corrosion and low toughness, and achieve control of production costs, improvement of mechanical properties, production The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

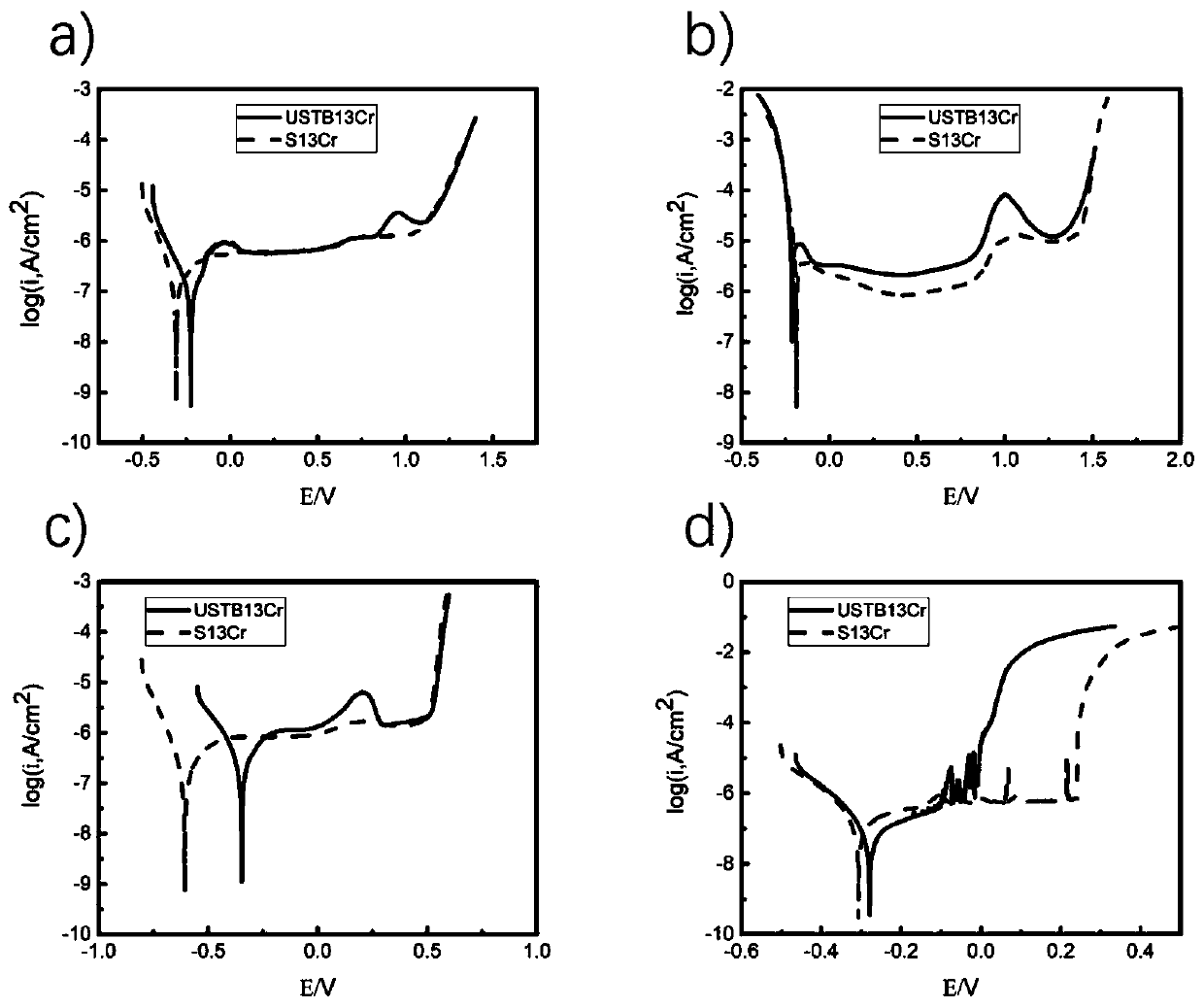

[0038] Examples and comparative examples

[0039] Table 1 shows the chemical composition ratios of the involved high-strength and high-toughness austenitic stainless steel (denoted as USTB13Cr) and the commercially produced 13Cr-5Ni-2Mo super martensitic stainless steel (denoted as S13Cr).

[0040] Table 1 embodiment and comparative example chemical composition

[0041]

[0042]

[0043] The balance in Table 1 is Fe and unavoidable impurity elements.

[0044]The heat treatment process of the embodiment is hot forging (initiating temperature of 1200° C.), cold rolling (total reduction of 44%), and tempering (700° C. for 1 hour).

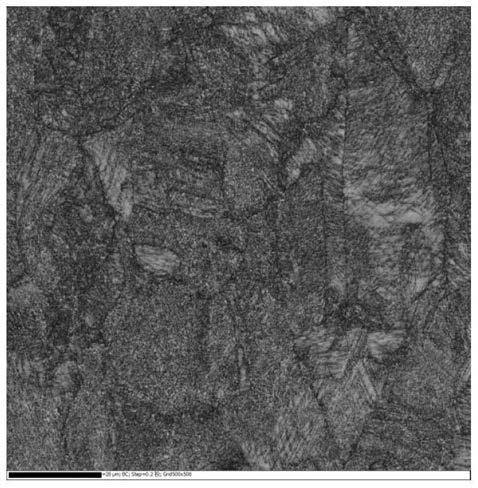

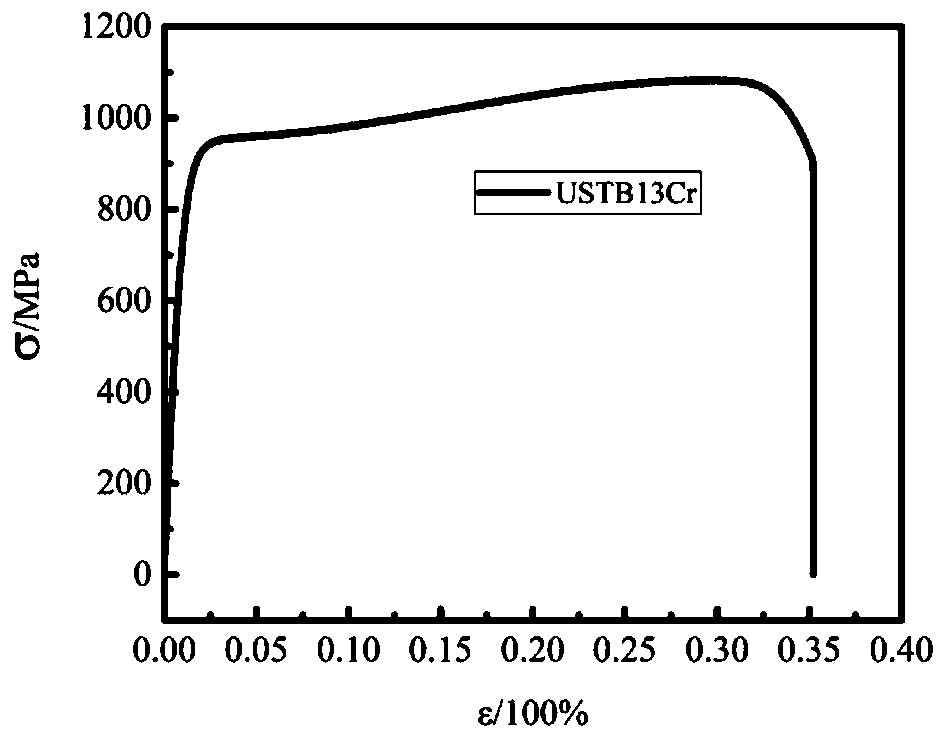

[0045] Example electron backscatter diffraction pattern (EBSD) such as figure 1 shown. The main microstructure of the embodiment is a fine-grained region and a coarse-grained region. The fine-grained region is a mixed state of nano-scale austenite and residual martensite. The coarse-grained area is the retained austenite without recrystalli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com