Hydrophilic cotton-like composite filament and manufacturing method thereof

A manufacturing method and composite wire technology, applied in the composite wire field, can solve the problems of not providing functional ITY composite wire products and production methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

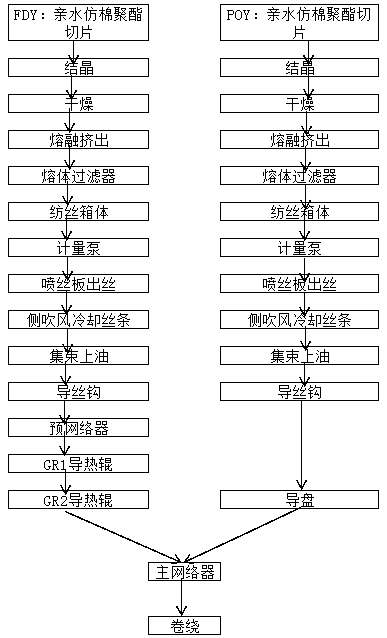

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will further illustrate the present invention with the following implementation cases of producing 150dtex / 108f hydrophilic cotton-like composite yarn, but the protection scope of the present invention is not limited to the implementation cases.

[0050] ①. Crystallize the hydrophilic cotton-like polyester chips in a fluidized bed, the crystallization temperature is 138°C, and the crystallization time is 15 minutes;

[0051] ②. After the crystallization is completed, put the hydrophilic imitation cotton slices into the material tower for drying. The drying temperature is 133°C, the drying time is 6h, and the dew point temperature is -95°C;

[0052] ③. The dried hydrophilic imitation cotton slices are respectively put into different screw extruders or the same screw extruder for melt extrusion, the screw pressure is 11.0MPa, and the temperature of each zone is 255°C, 262°C, 264°C , 268°C, 268°C;

[0053] ④. The melt passes through different melt fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com