Transformation method applicable to spandrel structure of two-way curved arch bridge

A technology for double-curved arch bridges and arch bridges, which is applied in the renovation of buildings on arches and in the field of renovation of buildings on arches with cast-in-place concrete with steel bottom formwork. High requirements for mechanical equipment and other issues, to achieve the effect of improving driving comfort and durability, shortening the construction period, and simple and orderly construction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following describes the present invention in detail with reference to the drawings and specific embodiments.

[0032] A reconstruction method suitable for buildings on double-curved arch bridges, including the following steps:

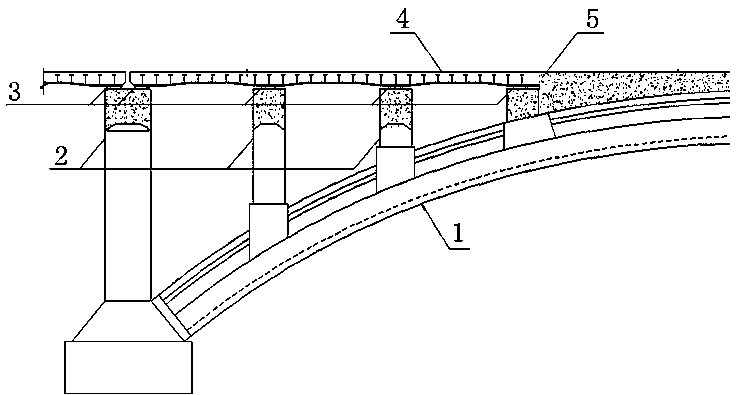

[0033] S1. The double-curved arch bridge after removing the arch on the building, such as figure 1 As shown, the main arch ring part of the double-curved arch bridge has a solid web section of the vault and an open web section of the arch bridge at both ends;

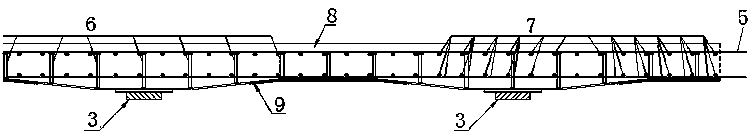

[0034] S2. The transverse partition wall connecting the open web section of the high arch bridge and the solid web section of the vault, the top surface is flush or flat;

[0035] S3. Place a PTFE slide support on the top of the transverse partition wall;

[0036] S4. Several steel bottom molds are hoisted to the support in a continuous plate shape, a number of shear nails welded on the inner side of the steel bottom mold, and the shear nails are welded with the laid double-layer steel mesh as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com