Humidity sensor based on electrospinning nanofiber fabric

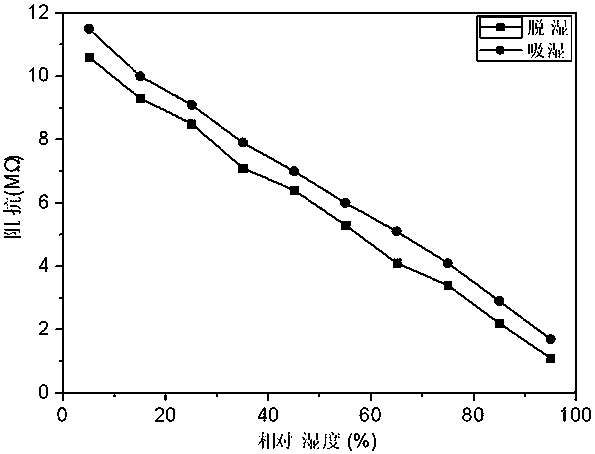

A humidity sensor and nanofiber technology, applied in the direction of electrochemical variables of materials, etc., can solve the problem of no contribution to sensor sensitivity and stability, and achieve the effects of low cost, high sensitivity and guaranteed stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Polyamide 6 / carbon nanotube nanofiber yarn was prepared by multi-needle water-bath electrospinning, in which the content of carbon nanotubes (single-walled carbon nanotubes, diameter 1-2nm, length 5-30μm) was 1%, and the yarn The linear density is 17.6tex, and then the plain weave nanofiber fabric is woven with a C / 401 rapier loom (Tianjin Longda Co., Ltd.). The weaving parameters are: the warp density of the upper machine is 450 pieces / 10cm, the weft density of the upper machine is 250 pieces / 10cm, the width is 24cm, the reed number is 15, and the number of penetrations is 3.

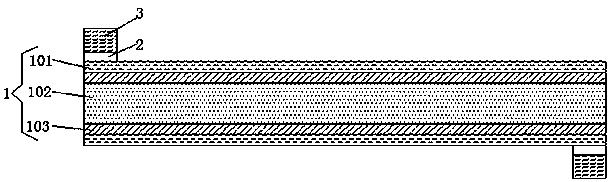

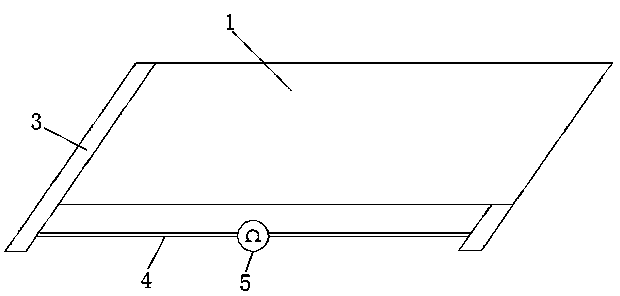

[0034] Cut out a rectangular nanofiber fabric with a length of 3 cm and a width of 1 cm, and use magnetron sputtering to coat it. The material is gold and the thickness is 200 nm. Then Fe with a mass ratio of 8:2 2 o 3 Mix the powder with ZnO as a humidity sensitive material to form a film with a thickness of 3 mm on the gold-plated nanofiber fabric to form a nanofiber fabric A1 with a humidit...

Embodiment 2

[0037] Polyamide 6 / carbon nanotube nanofiber yarn was prepared by multi-needle water-bath electrospinning, in which the content of carbon nanotubes (single-walled carbon nanotubes, diameter 1-2nm, length 5-30μm) was 1%, and the yarn The linear density is 17.6tex, and then the plain weave nanofiber fabric is woven with a C / 401 rapier loom (Tianjin Longda Co., Ltd.). The weaving parameters are: the warp density of the upper machine is 450 pieces / 10cm, the weft density of the upper machine is 250 pieces / 10cm, the width is 24cm, the reed number is 15, and the number of penetrations is 3.

[0038] Cut out a rectangular nanofiber fabric with a length of 3 cm and a width of 1 cm, and use magnetron sputtering to coat it. The material is gold and the thickness is 200 nm. Then TiO with a mass ratio of 5:5 2 Mix the powder with ZnO as the humidity sensitive material layer 101 to form a film with a thickness of 3 mm on the gold-plated nanofiber fabric to form the nanofiber fabric A1 with...

Embodiment 3

[0041] Polyamide 6 / carbon nanotube nanofiber yarn was prepared by multi-needle water-bath electrospinning, in which the content of carbon nanotubes (single-wall carbon nanotubes, diameter 1-2nm, length 5-30μm) was 0.5%, and the yarn The linear density is 17.6tex, and then the plain weave nanofiber fabric is woven with a C / 401 rapier loom (Tianjin Longda Co., Ltd.). The weaving parameters are: the warp density of the upper machine is 450 pieces / 10cm, the weft density of the upper machine is 250 pieces / 10cm, the width is 24cm, the reed number is 15, and the number of penetrations is 3.

[0042] Cut out a rectangular nanofiber fabric with a length of 3 cm and a width of 1 cm, and use magnetron sputtering to coat it. The material is gold and the thickness is 200 nm. Then Fe with a mass ratio of 8:2 2 o 3 Mix the powder with ZnO as the humidity sensitive material layer 101 to form a film with a thickness of 3 mm on the gold-plated nanofiber fabric to form the nanofiber fabric A1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com