Graphene transparent conductive film, preparation method of graphene transparent conductive film and liquid crystal film

A technology of transparent conductive film and graphene, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of foreign matter affecting the yield and quality of liquid crystal display devices, generating static electricity, and easily breaking down substrates, so as to avoid alignment layer and Effect of electrode separation and surface smoothing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

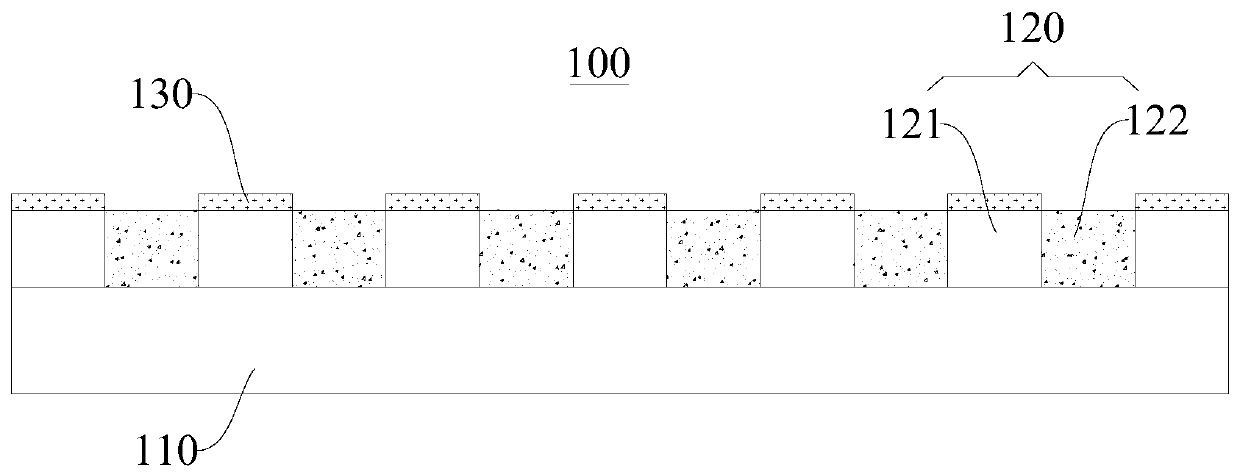

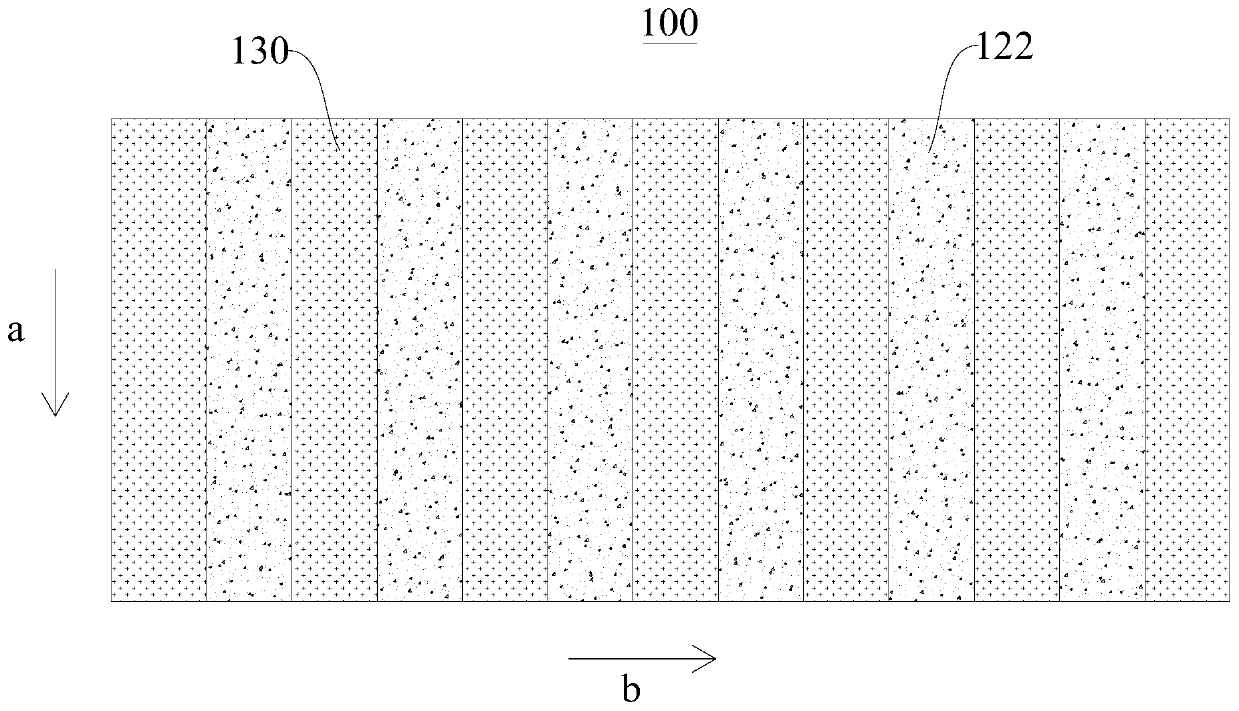

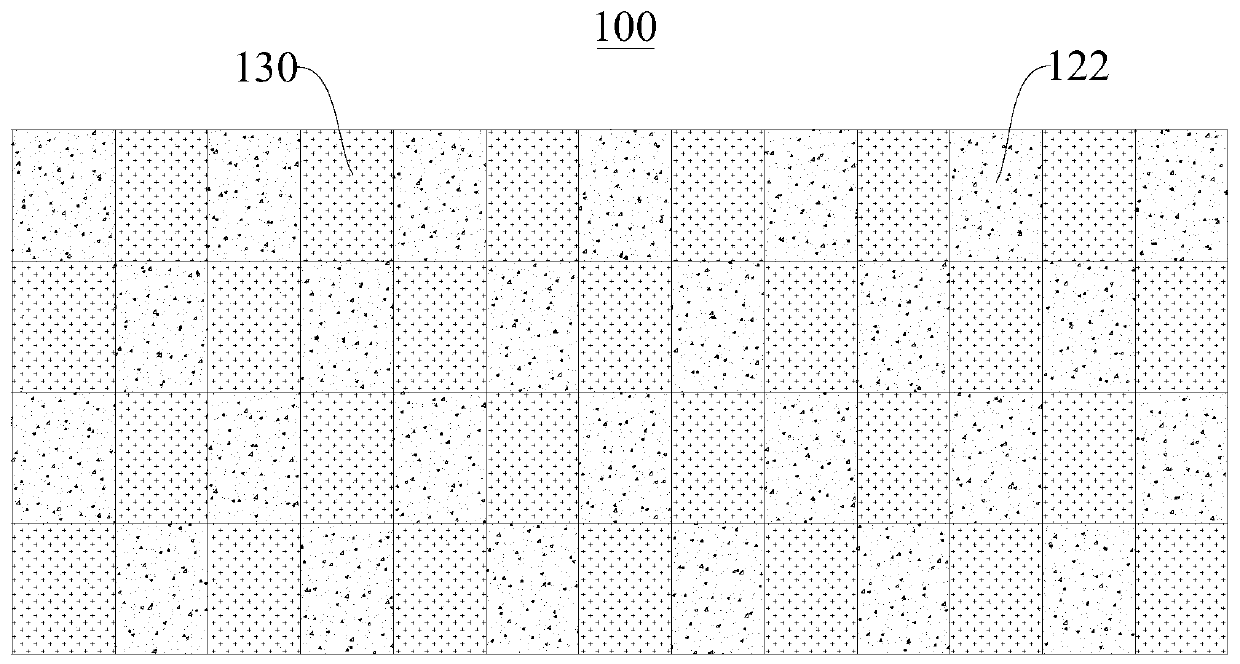

[0083] A graphene transparent conductive film 100 includes a substrate layer 110, a patterned graphene layer 120, and a vertical alignment layer 130 arranged in sequence.

[0084] Wherein, the base material layer 110 is made of PI and has a thickness of 0.5 μm. The thickness of the patterned graphene layer 120 is 0.3 nm. The vertical alignment agent constituting the vertical alignment layer 130 is dodecylbenzenesulfonic acid. The area percentage of the vertical alignment layer 130 and the graphene region 122 is 5%:95%.

[0085] A method for preparing the above-mentioned graphene transparent conductive film 100 includes:

[0086] The substrate layer 110 is ultrasonically cleaned with ethanol, acetone, and deionized water, rinsed with deionized water, and then air-dried or dried with nitrogen.

[0087] Using chemical vapor deposition, a graphene layer is formed on the surface of the cleaned substrate layer 110. The graphene layer is covered with a fine metal mask, and the uncovered a...

Embodiment 2

[0089] A graphene transparent conductive film 100 includes a substrate layer 110, a patterned graphene layer 120, and a vertical alignment layer 130 arranged in sequence.

[0090] Wherein, the base material layer 110 is made of PET and has a thickness of 1 μm. The thickness of the patterned graphene layer 120 is 0.35 nm. The vertical alignment agent constituting the vertical alignment layer 130 is octadecylbenzenesulfonic acid. The area percentage of the vertical alignment layer 130 and the graphene region 122 is 30%:70%.

[0091] A method for preparing the above-mentioned graphene transparent conductive film 100 includes:

[0092] The substrate layer 110 is ultrasonically cleaned with ethanol, acetone, and deionized water, rinsed with deionized water, and then air-dried or dried with nitrogen.

[0093] A spin coating method is used to form a graphene oxide layer on the surface of the cleaned substrate layer 110. The graphene oxide layer is covered with a fine metal mask, and the u...

Embodiment 3

[0095] A graphene transparent conductive film 100 includes a substrate layer 110, a patterned graphene layer 120, and a vertical alignment layer 130 arranged in sequence.

[0096] Wherein, the base material layer 110 is made of PI and has a thickness of 10 μm. The thickness of the patterned graphene layer 120 is 1.1 nm. The vertical alignment agent constituting the vertical alignment layer 130 is 1,4'-dodecyloxy-4-hydroxybiphenyl. The area percentage of the vertical alignment layer 130 and the graphene region 122 is 50%:50%.

[0097] A method for preparing the above-mentioned graphene transparent conductive film 100 includes:

[0098] The substrate layer 110 is ultrasonically cleaned with ethanol, acetone, and deionized water, rinsed with deionized water, and then air-dried or dried with nitrogen.

[0099] Using chemical vapor deposition, a graphene layer is formed on the surface of the cleaned substrate layer 110. Cover the graphene layer with a fine metal mask, and perform oxidat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com