Superconducting magnet and magnetically-controlled Czochralski single crystal equipment

A superconducting magnet, Czochralski single crystal technology, applied in superconducting magnets/coils, single crystal growth, single crystal growth and other directions, can solve the problems of affecting the quality of single crystals, the magnetic field is not stable enough, and the space occupied by the power supply. Conducive to space layout and operation safety, saving power cost and usage cost, and preventing ripple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

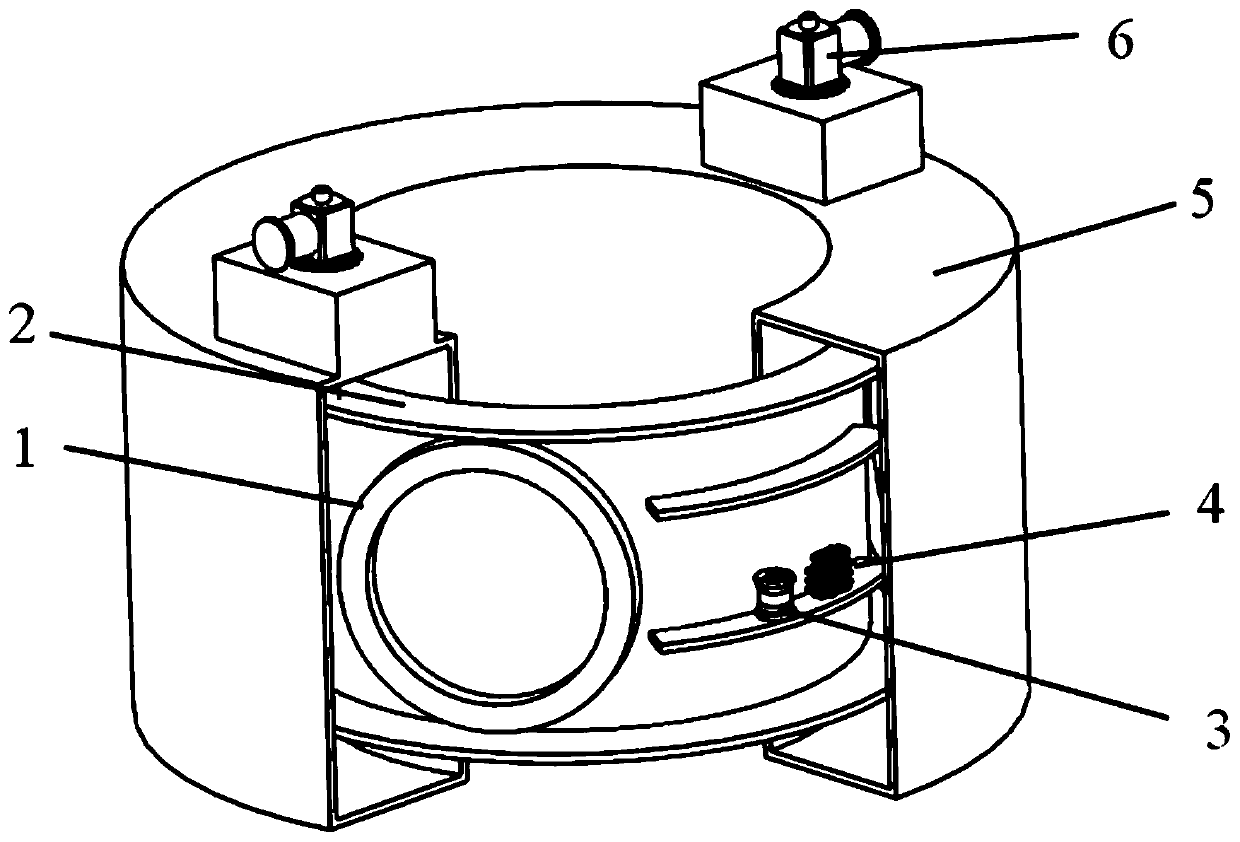

[0028] figure 1 It is a schematic structural diagram of a superconducting magnet provided in Embodiment 1 of the present invention. Such as figure 1 As shown, the superconducting magnet is used in the preparation process of magnetron Czochralski single crystal, and specifically includes a superconducting switch 3, a superconducting coil 1, a coil frame 2 and a cryostat 5, wherein: the number of superconducting coils 1 is one set One or more groups are fixed on the coil frame 2, and a plurality of superconducting coils 1 are connected in series. There is at least one superconducting switch 3, which is connected in parallel with the superconducting coil 1, and is used to close when the superconducting coil 1 is excited to a set magnetic field by an excitation power supply, so as to connect each superconducting coil 1 to form a closed loop. The superconducting switch 3 is fixed on the set low magnetic field area of the bobbin 1 . The coil bobbin 2 is placed in the cryostat 5...

Embodiment 2

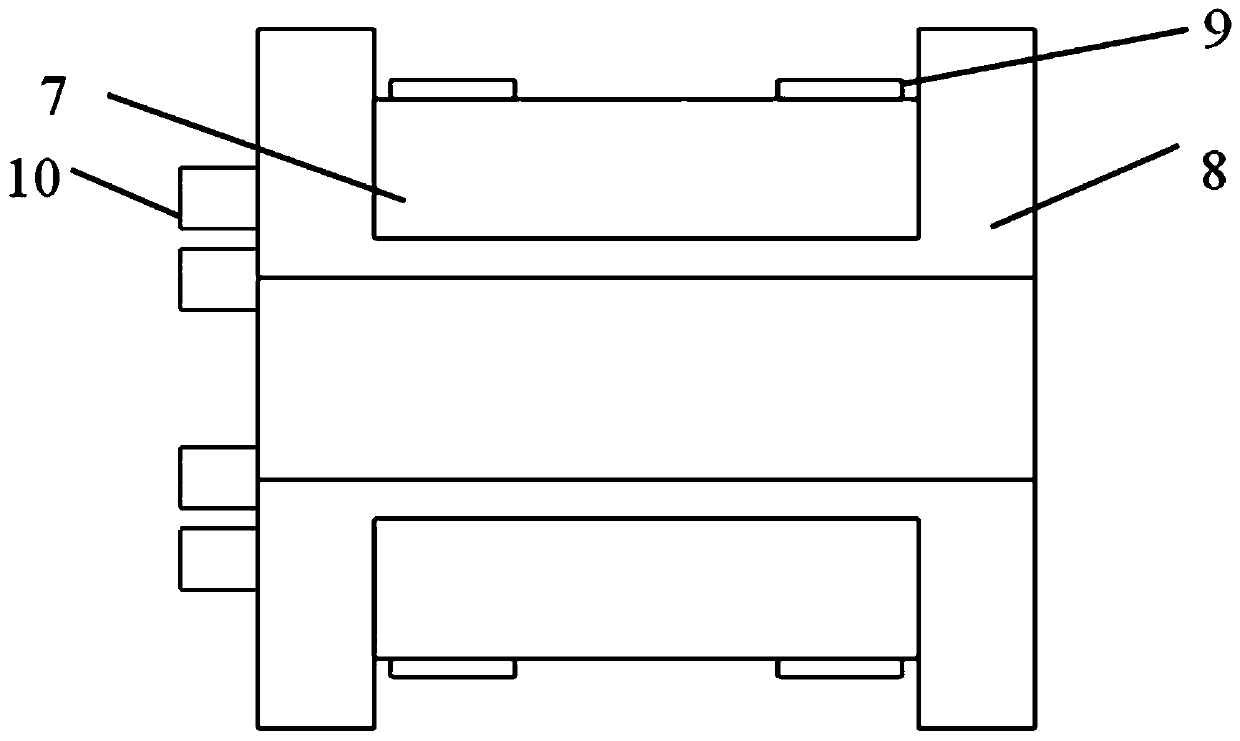

[0040] figure 2 It is a schematic plan view of the structure of the superconducting switch in Embodiment 2 of the present invention. On the basis of Embodiment 1, preferably, the structure of the cryostat 5 is a structure soaked in liquid helium, and the superconducting switch 3 can be selected as a heating type superconducting switch. .

[0041] then as figure 2 As shown, the heated superconducting switch specifically includes: a non-inductive coil 7 , a heater 9 , a switch frame 8 and a terminal 10 .

[0042] The non-inductive coil 7 is wound on the switch skeleton 8 in a non-inductive winding manner, the incoming and outgoing lines of the non-inductive coil 7 are connected to the terminal 10, the superconducting coil 1 is connected to the terminal 10, and the heater 9 is connected to the terminal 10. The non-inductive coil 7 is placed close to it, and is wound and fixed with glass silk cloth. The incoming and outgoing wires of the heater 9 are drawn from the superconducti...

Embodiment 3

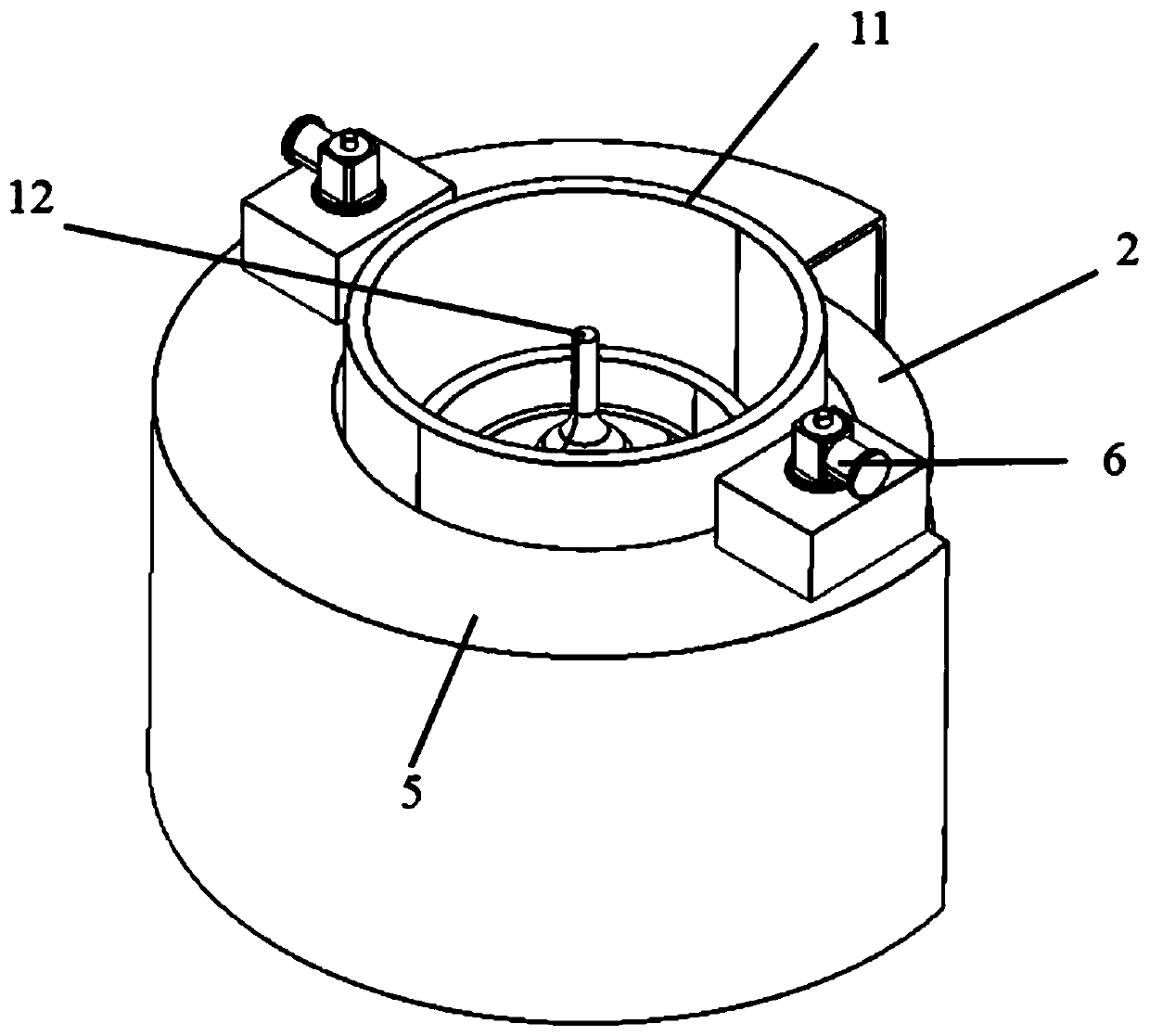

[0051] image 3 It is a schematic axial side view of the magnetron Czochralski single crystal device in Embodiment 3 of the present invention. Such as image 3 As shown, Embodiment 3 of the present invention provides a magnetron Czochralski single crystal device, including a single crystal furnace 11 and a superconducting magnet provided by any embodiment of the present invention. The superconducting magnet is arranged on the outside of the single crystal furnace 11, and is used to close the superconducting switch 3 when the excitation power source is excited to the set magnetic field, so that the superconducting coil 1 forms the magnetic field required for the magnetically controlled Czochralski single crystal, so as to remove Excitation power supply.

[0052] The magnetron Czochralski single crystal equipment provided in this embodiment, when preparing a single crystal, turn on the refrigerator 6 switch after the magnet is evacuated, so that the superconducting magnet is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com