Graphene photoelectric detector with sub-wavelength metal grating structure

A photodetector and metal grating technology, applied in the field of optical communication, can solve the problems of low detector responsivity and low light absorption efficiency of graphene, and achieve the effect of improving responsivity and enhancing light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

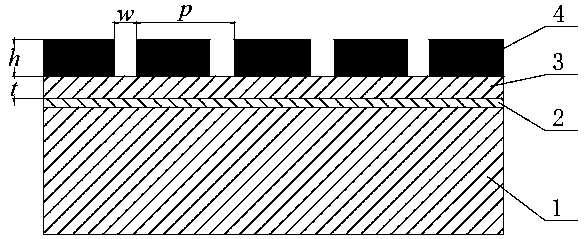

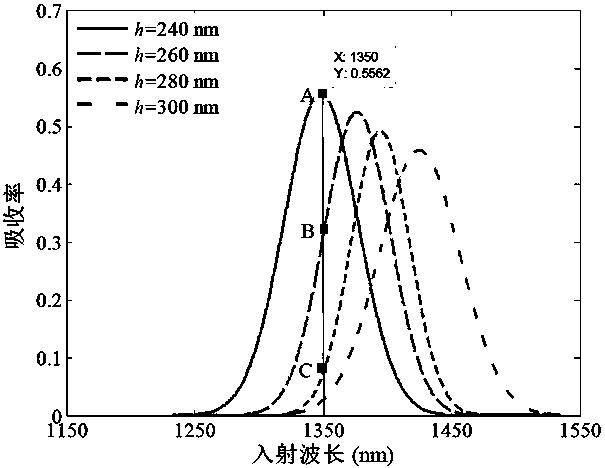

[0029] The graphene photodetector structure of the present embodiment sees figure 1 As shown, wherein the grating period is 400nm, the slit width is 100nm, the grating height is 240nm, the thickness of the buffer layer 3 is 20nm, and the buffer layer 3 is made of silicon material. The sub-wavelength metal grating is made of silver material, and its relative permittivity is the Drude model:

[0030]

[0031] In formula (1), γ and ω represent the electron collision frequency and the angular frequency of the incident light respectively, i is the imaginary unit, ε ∞ and ω p are the infinite frequency dielectric constant and the surface plasmon frequency, respectively.

[0032] The relative permittivity of graphene 2 is ε g =1+iσ g / ωε 0 Δ, Δ is the thickness of single-layer graphene 2, ω is the angular frequency of the incident light, i is the imaginary unit, ε 0 is the vacuum permittivity, σ g is the conductivity constant, σ g = σ intra +σ inter ,in

[0033]

[0...

Embodiment 2

[0038] The structure of the graphene photodetector in this embodiment is the same as that in Embodiment 1, except that the grating height is 260 nm. figure 2 Also shows the light absorption spectrum figure of the graphene photodetector involved in the present embodiment, in addition image 3 It also shows the corresponding COMSOL software simulation electric field distribution diagram (see image 3 in part b).

Embodiment 3

[0040] Same as the structure of embodiments 1 and 2, the difference is that the height of the grating in this embodiment is 280nm, figure 2 The light absorption spectrum of the graphene photodetector involved in this embodiment is shown in image 3 The corresponding COMSOL software simulation electric field distribution diagram is shown in (see image 3 in part c).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Slit width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com