Organic solar cell employing ternary component as active layer

A solar cell and organic active layer technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of poor thermal stability and mechanical properties, expensive fullerene acceptors, poor optical properties, etc., to increase short circuit Current, improve photoelectric conversion efficiency, enhance the effect of light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

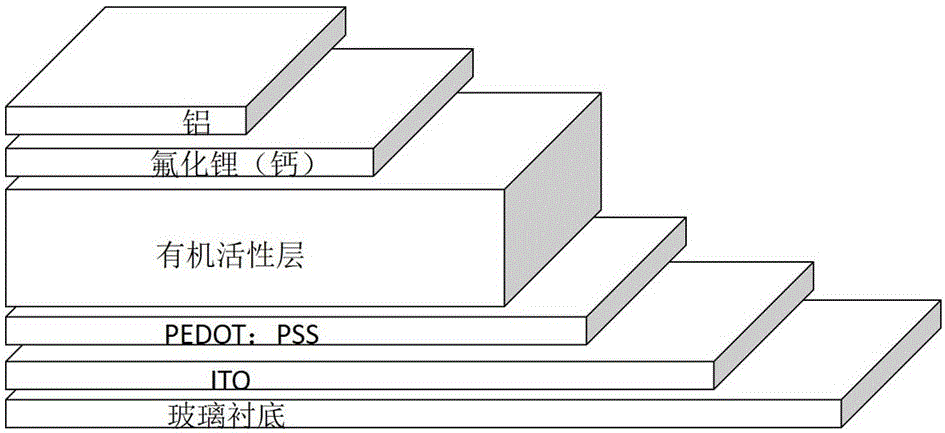

[0025] The technical solution of the present invention provides a ternary system polymer-non-fullerene organic solar cell that does not require fullerene and its derivatives. The structure is shown in Figure 1. The organic solar cell adopts an upright structure, from bottom to bottom The above sequence is: transparent glass substrate, transparent conductive cathode ITO, material is PEDOT: PSS cathode buffer layer, organic active layer, material is lithium fluoride or calcium anode buffer layer, aluminum metal anode. The thickness of the anode buffer layer is 0.6-10 nm, and the thickness of the cathode buffer layer is 30-50 nm.

[0026] Clean the substrate composed of glass transparent substrate and transparent conductive cathode ITO with acetone, soapy water, isopropanol and acetone respectively; after drying, spin-coat a layer of 40-45nm PEDOT on the surface of transparent conductive cathode ITO:PSS, And the formed film was annealed (140°C, 15min).

[0027] Adopt spin coatin...

Embodiment 2

[0047] Clean the substrate composed of glass transparent substrate and transparent conductive cathode ITO with acetone, soapy water, isopropanol and acetone respectively; after drying, spin-coat a layer of 40-45nm PEDOT on the surface of transparent conductive cathode ITO:PSS, And the formed thin film is annealed (140 ℃, 15min); On the cathode buffer layer, the organic active layer is prepared by spin coating to prepare samples respectively:

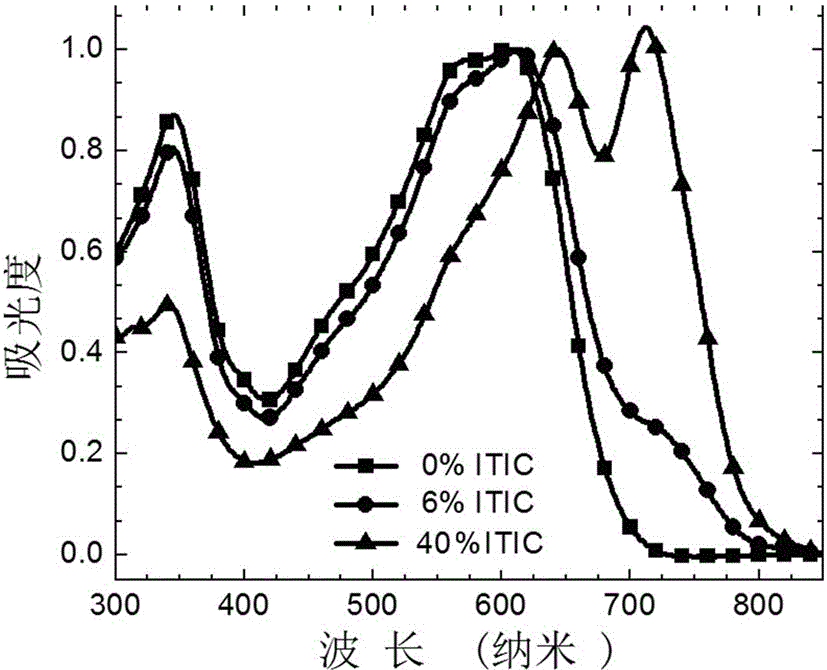

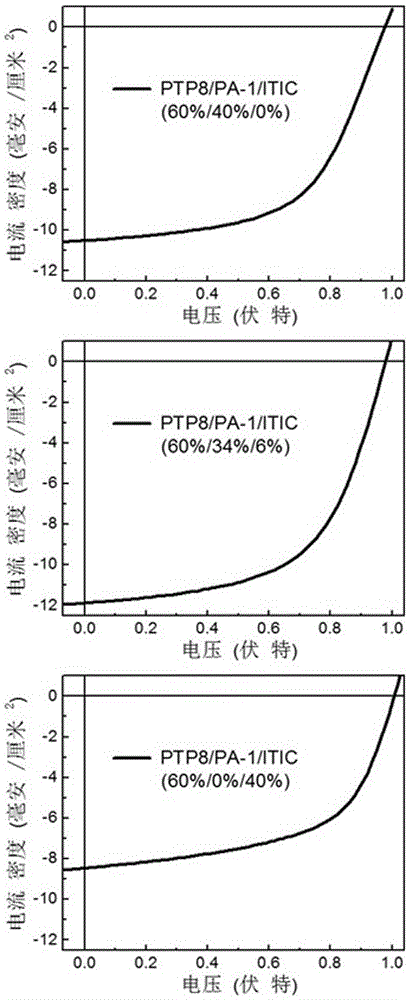

[0048] PT8:PA-1:ITIC(60%:40%:0%);

[0049] PTP8:PA-1:ITIC (60%:34%:6%).

[0050] The structural formula of PT8 is:

[0051] .

[0052] All organic materials are dissolved in chloroform, and the thickness of the film obtained by spin coating is about 80-100nm (1000rpm, 40s). The organic active layer does not need heat treatment; the modification layer LiF (0.6nm) and metal are deposited on the organic layer by thermal evaporation. Electrode Al (100nm).

[0053] Control group PT8:PA-1:ITIC(60%:40%:0%), under standard test conditions:...

Embodiment 3

[0057] Clean the substrate composed of glass transparent substrate and transparent conductive cathode ITO with acetone, soapy water, isopropanol and acetone respectively; after drying, spin-coat a layer of 40-45nm PEDOT on the surface of transparent conductive cathode ITO:PSS, And the formed thin film is annealed (140 ℃, 15min); On the cathode buffer layer, the organic active layer is prepared by spin coating and prepares samples respectively:

[0058] PTQ1:N2200:ITIC(60%:40%:0%);

[0059] PTQ1:N2200:ITIC(60%:34%:6%) .

[0060] The structural formula of PTQ1 is:

[0061] ;

[0062] The structural formula of N2200 is:

[0063] .

[0064] All organic materials are dissolved in chloroform, and the thickness of the film obtained by spin coating is about 80-100nm (1000rpm, 40s). The organic active layer does not need heat treatment; the modification layer LiF (0.6nm) and metal are deposited on the organic layer by thermal evaporation. Electrode Al (100nm).

[0065] Contro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com