Preparation method of high-density garnet all-solid electrolyte under low temperature and application of high-density garnet all-solid electrolyte

A garnet-type, dense technology, applied in the direction of electrolytes, circuits, electrical components, etc., can solve the problem of low density and achieve the effect of promoting industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment prepares Li according to the following steps 7 La 3 Zr 2 o 12 Electrolyte sheet:

[0027] 1. Add LiOH·H 2 O, La 2 o 3 , ZrO 2 Weigh it according to the stoichiometric ratio, add it to the ball mill tank, and add an excess of 10% Li, add an appropriate amount of isopropanol to ball mill for 24 hours, and dry it at 70 °C for 1 hour after the end.

[0028] 2. Take out the obtained powder, put it into a corundum porcelain boat for compaction, then raise the temperature to 900°C at a rate of 2°C / min, and finish the heat preservation for 9 hours.

[0029] 3. Take part of the obtained precursor powder and process it again with high-energy ball milling for 45 minutes. After that, mix the precursor powder after high-energy ball milling treatment with that without high-energy ball milling in a mass ratio of 3:7, and use a powder tablet press Compressed into tablets at 30MPa.

[0030] 4. Put the electrolyte sheet into the corundum porcelain boat, and sprea...

Embodiment 2

[0032] This embodiment prepares Li according to the following steps 6.7 La 3 Zr 1.7 Nb 0.3 o 12 Electrolyte sheet:

[0033] 1. Will Li 2 CO 3 , La 2 o 3 , ZrO 2 , Nb 2 o 5 Weigh it according to the stoichiometric ratio, add it to the ball mill jar, and add an excess of 15% Li, add an appropriate amount of isopropanol and ball mill it for 24 hours, and then dry it at 80°C for 1 hour.

[0034] 2. Take out the obtained powder, put it into a corundum porcelain boat for compaction, then raise the temperature to 900°C at a rate of 2°C / min, and finish the heat preservation for 9 hours.

[0035] 3. Take part of the obtained precursor powder and process it again with high-energy ball milling for 45 minutes, then mix the precursor powder after high-energy ball milling treatment with that without high-energy ball milling in a mass ratio of 4:6, and use a powder tablet press Compressed into tablets at 30MPa.

[0036] 4. Put the electrolyte sheet into the corundum porcelain bo...

Embodiment 3

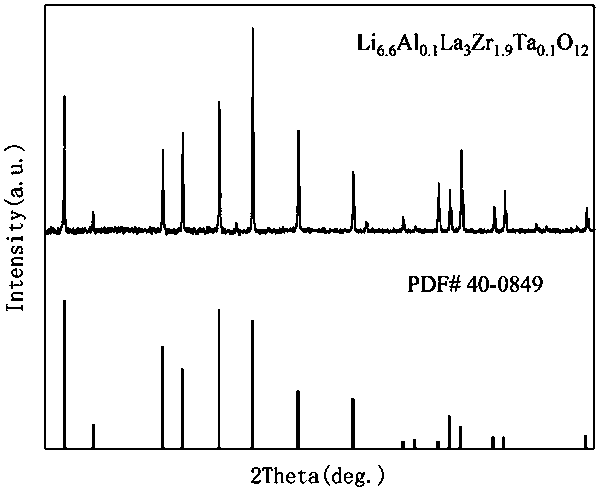

[0038] This embodiment prepares Li according to the following steps 6.5 al 0.1 La 3 Zr1.5 Ta 0.5 o 12 Electrolyte sheet:

[0039] 1. Will Li 2 CO 3 , La 2 o 3 , ZrO 2 、 Ta 2 o 5 Weigh it according to the stoichiometric ratio, add it to the ball mill tank, and add an excess of 10% Li, add an appropriate amount of isopropanol to ball mill for 24 hours, and dry it at 70 °C for 1 hour after the end.

[0040] 2. Take out the obtained powder, put it into a corundum porcelain boat for compaction, then raise the temperature to 850°C at a rate of 2°C / min, and finish the heat preservation for 12 hours.

[0041] 3. Take part of the obtained precursor powder and process it again with high-energy ball milling for 45 minutes. After that, mix the precursor powder after high-energy ball milling treatment with that without high-energy ball milling in a mass ratio of 3:7, and use a powder tablet press Compressed into tablets at 30MPa.

[0042] 4. Put the electrolyte sheet into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Theoretical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com