A method for ecological restoration of landfill closure by utilizing deeply mineralized stale garbage

A technology for ecological restoration and landfill, which is applied in the field of waste treatment and comprehensive utilization of resources, can solve problems such as accelerating the stabilization process of landfill, achieve excellent physical and chemical properties and hydraulic properties, accelerate microbial degradation reactions, and facilitate removal effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

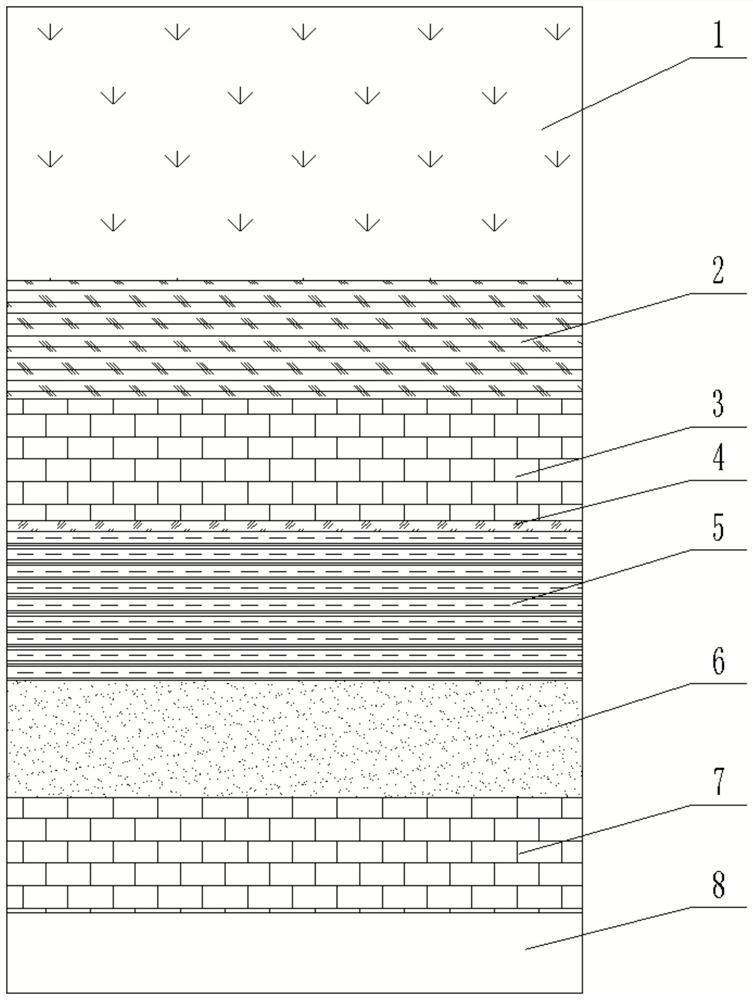

[0023] A method of using deeply mineralized stale waste to compound for ecological restoration of landfill closures. The deeply mineralized stale waste is sieved to remove rubber, plastics and aggregates, and the fine material under the sieve is humus. Such as figure 1 As shown, on the garbage layer 8 in the landfill, there are vegetation layer 1, drainage layer, anti-seepage layer and exhaust layer from top to bottom, and they are constructed sequentially from bottom to top during construction. Described exhaust layer is two layers, and exhaust layer upper layer 6 is the sand and gravel of particle diameter 20-50mm, and thickness is 22cm; The exhaust layer lower layer is deep mineralization obsolete garbage humus layer, and thickness is 22cm. The anti-seepage layer has two layers, the upper layer 4 of the anti-seepage layer is an HDPE film with a thickness of 1mm, and the lower layer 5 of the anti-seepage layer is a composite layer of clay and deeply mineralized stale garbage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com