Bamboo-shaped thin-wall pipe structure easy-to-assemble multi-directional self-locking energy absorbing system

A bamboo-shaped, thin-walled tube technology, applied in the direction of low internal friction springs, shock absorbers, spring/shock absorbers, etc., can solve the problem of increasing installation time costs, manpower and material costs, secondary damage, and reducing energy absorption Efficiency and other issues, to achieve good flexibility and adjustability, strong economy and emergency, easy to disassemble and install the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

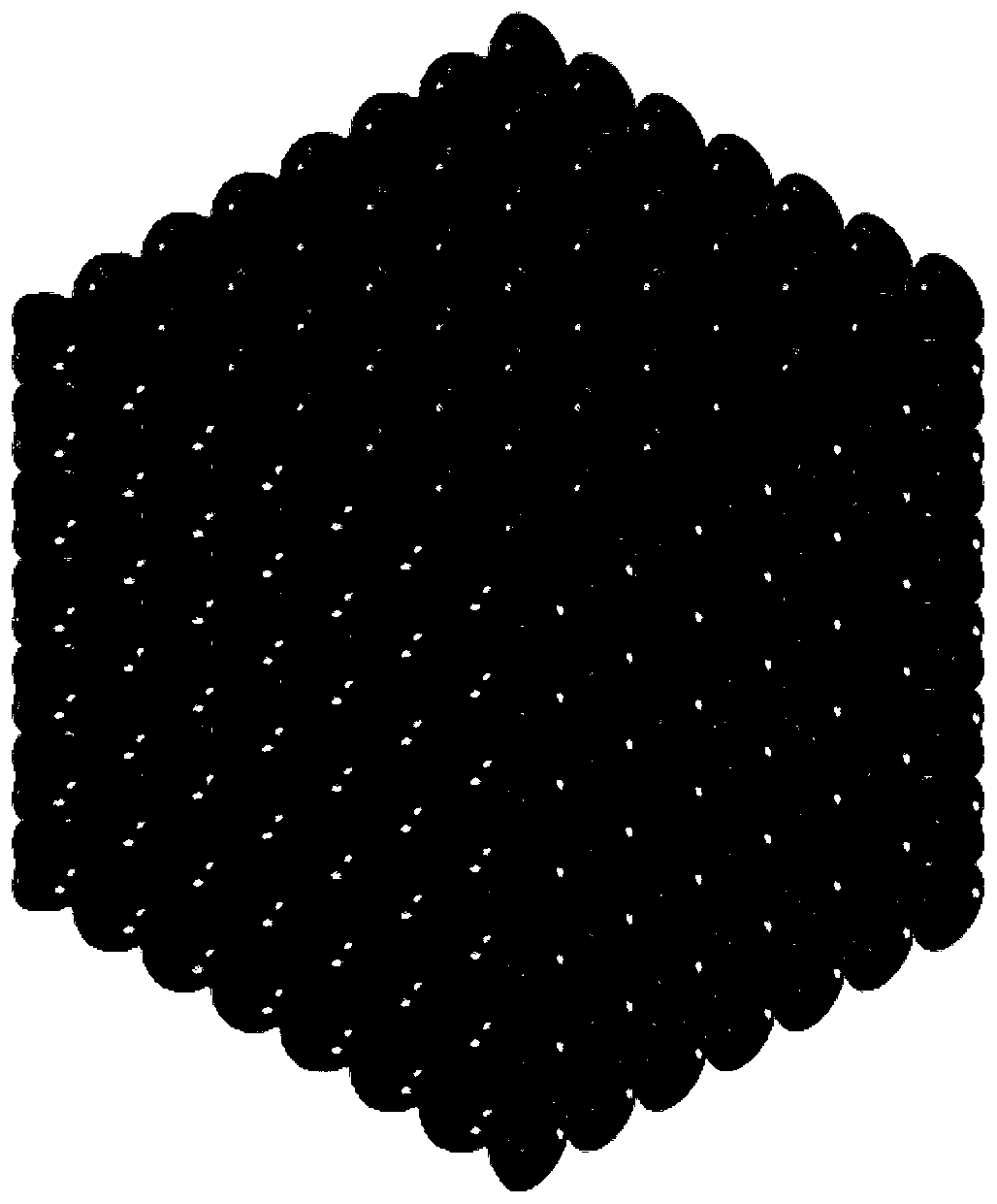

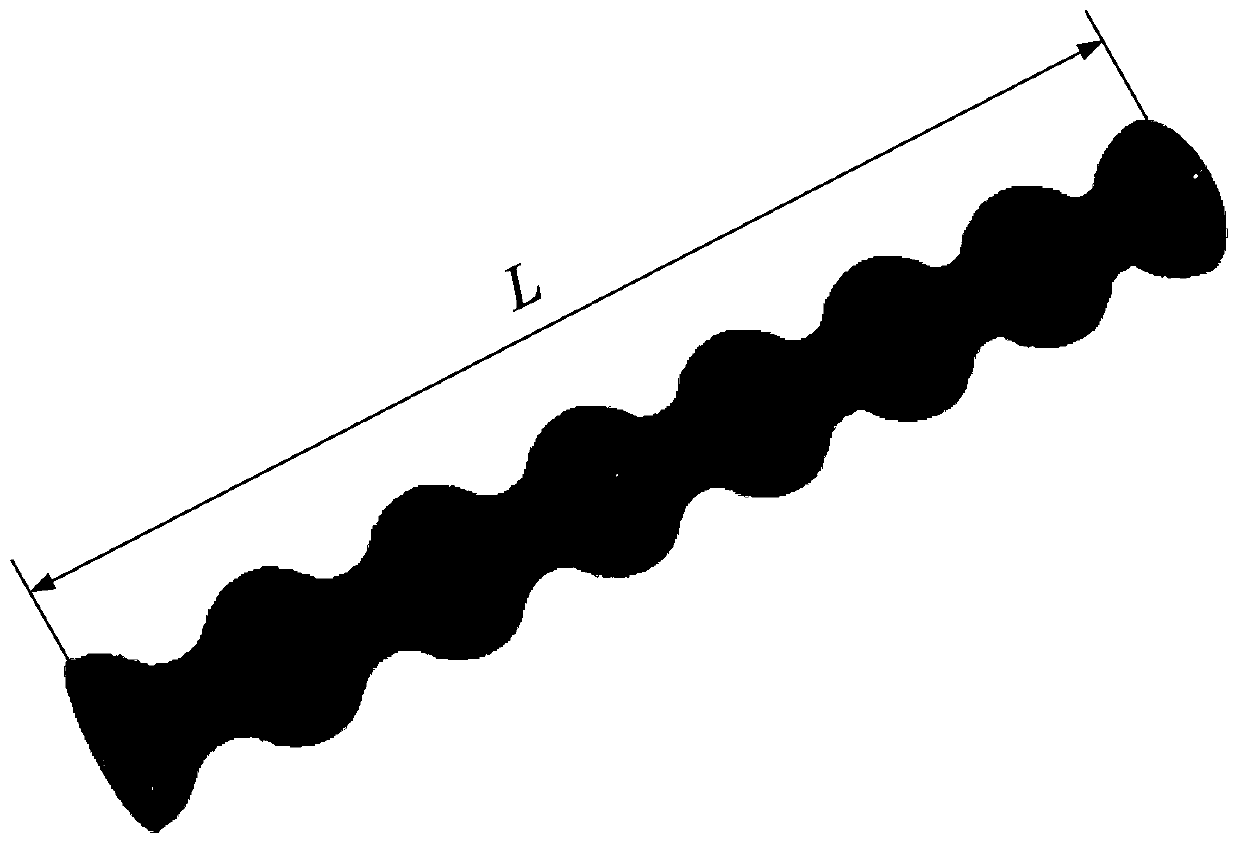

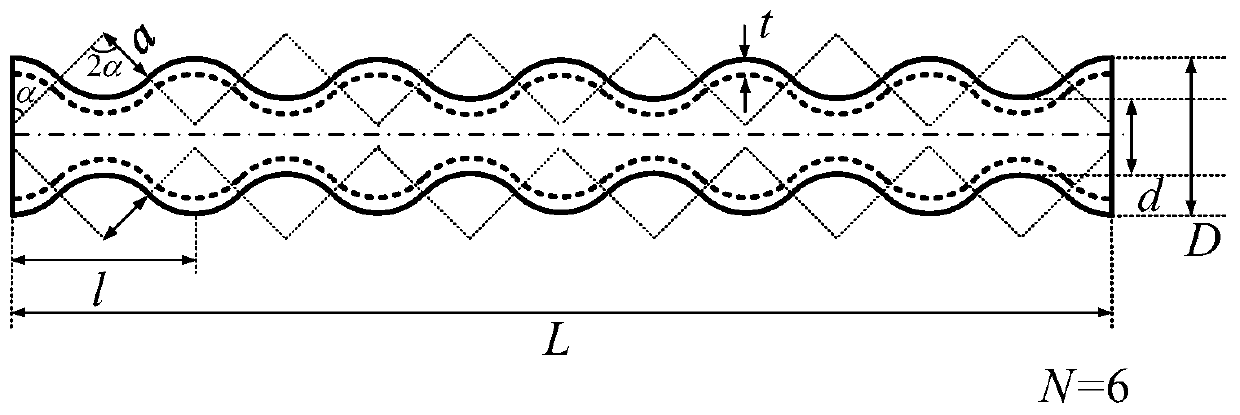

[0032] Example 1: Analysis of the longitudinal load of a multi-directional self-locking energy-absorbing system with a bamboo-shaped thin-walled tube structure that is easy to assemble

[0033] Calculate the energy-absorbing effect of the corresponding bamboo-like thin-walled tube multi-directional self-locking energy-absorbing system that needs to be installed when the impacting object's speed v=72km / h=20m / s and the impacting object's mass is m=133kg through simulation. The selected combined structure consists of 72 bamboo-like thin-walled tube structures stacked staggered into 12 rows. The parameters of a single substructure are as follows: the outer diameter of the largest circular section D = 20mm, the outer diameter of the smallest circular section d = 10mm, the number of cycles of section size change N = 6, the thickness T = 0.5mm, the axial length L = 124.8mm, The outer contour of the section passing through the axis contains the central angle α=45o of the small circula...

Embodiment 2

[0035] Example 2: Analysis of the lateral load of a multi-directional self-locking energy-absorbing system with a bamboo-shaped thin-walled tube structure that is easy to assemble

[0036] Calculate the energy-absorbing effect of the corresponding bamboo-like thin-walled tube multi-directional self-locking energy-absorbing system that needs to be installed when the impacting object's speed v=72km / h=20m / s and the impacting object's mass is m=133kg through simulation. The selected combined structure consists of 72 bamboo-like thin-walled tube structures stacked staggered into 12 rows. The parameters of a single substructure are as follows: the outer diameter of the largest circular section D = 20mm, the outer diameter of the smallest circular section d = 10mm, the number of cycles of section size change N = 6, the thickness T = 0.5mm, the axial length L = 124.8mm, The outer contour of the section passing through the axis contains the central angle α=45o of the small circular arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com