A multi-directional self-locking energy-absorbing system with a bamboo-shaped thin-walled tube structure that is easy to assemble

A bamboo-shaped, thin-walled tube technology, used in elastic shock absorbers, springs/shock absorbers, low internal friction springs, etc. Energy efficiency and other issues, to achieve the effect of good flexibility and adjustability, strong economy and emergency, easy disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

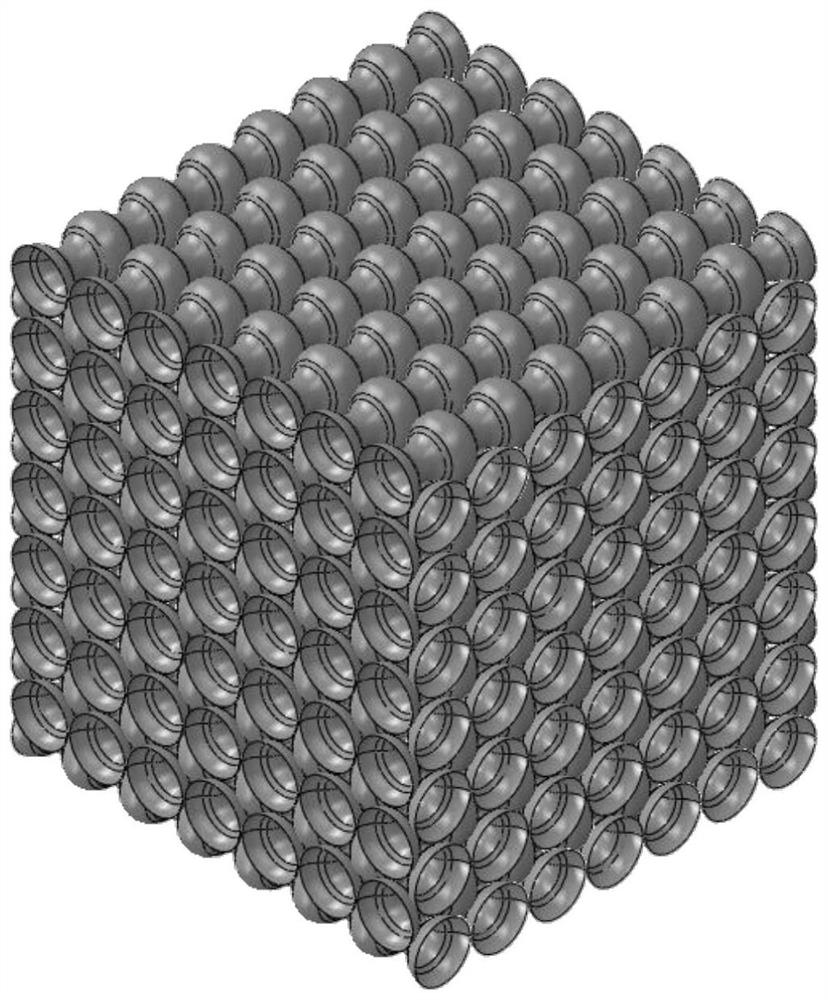

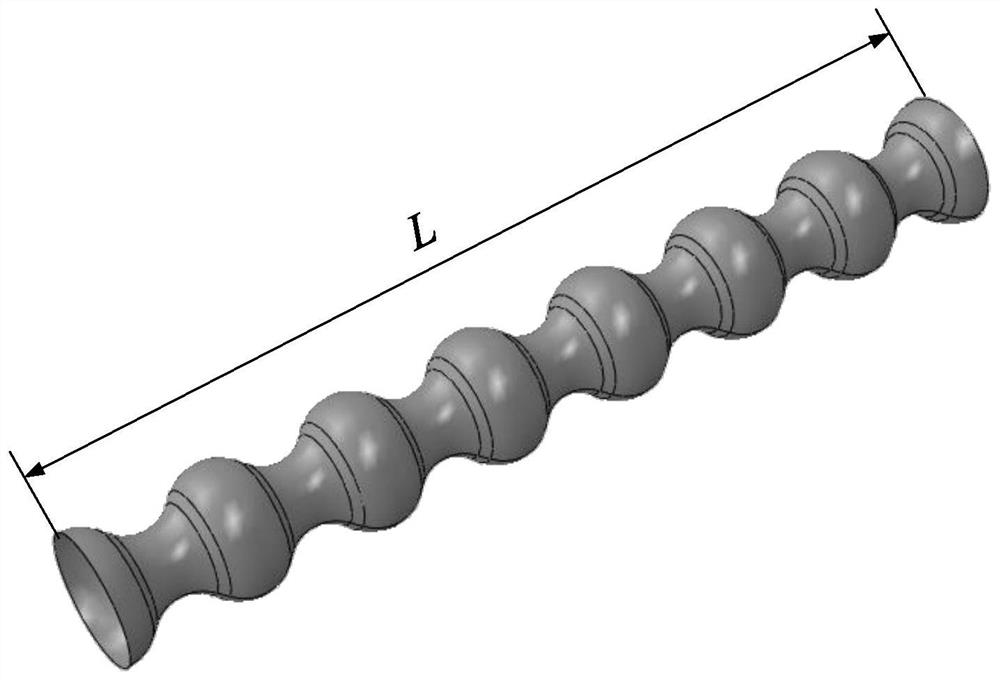

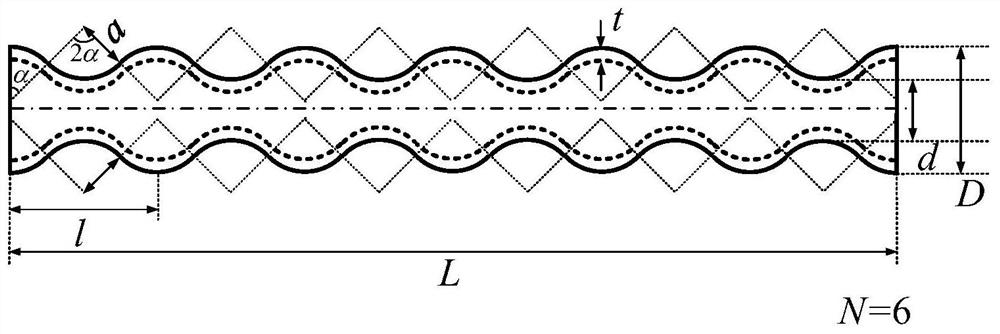

[0032] Example 1: Analysis of the longitudinal load of a multi-directional self-locking energy-absorbing system with a bamboo-shaped thin-walled tube structure that is easy to assemble

[0033] Calculate the energy-absorbing effect of the corresponding bamboo-like thin-walled tube multi-directional self-locking energy-absorbing system that needs to be installed when the impacting object's speed v=72km / h=20m / s and the impacting object's mass is m=133kg through simulation. The selected combined structure consists of 72 bamboo-like thin-walled tube structures stacked staggered into 12 rows. The parameters of a single substructure are as follows: the outer diameter of the largest circular section D = 20mm, the outer diameter of the smallest circular section d = 10mm, the number of cycles of section size change N = 6, the thickness T = 0.5mm, the axial length L = 124.8mm, The central angle α=45° of the small circular arc contained in the cross-sectional outer contour passing throug...

Embodiment 2

[0035] Example 2: Analysis of the lateral load of a multi-directional self-locking energy-absorbing system with a bamboo-shaped thin-walled tube structure that is easy to assemble

[0036] Calculate the energy-absorbing effect of the corresponding multi-directional self-locking energy-absorbing system of bamboo-like thin-walled tubes that need to be installed when the impacting object's speed v=72km / h=20m / s and the impacting object's mass is m=133kg through simulation. The selected combined structure consists of 72 bamboo-like thin-walled tube structures stacked staggered into 12 rows. The parameters of a single substructure are as follows: the outer diameter of the largest circular section D = 20mm, the outer diameter of the smallest circular section d = 10mm, the number of cycles of section size change N = 6, the thickness T = 0.5mm, the axial length L = 124.8mm, The central angle α=45° of the small circular arc contained in the cross-sectional outer contour passing through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com