Boiler using biomass bales as fuel

A biomass and fuel technology, applied in the boiler field, can solve the problems of reducing the thermal efficiency of the boiler, difficult cleaning, and inability to directly burn bundled straws, etc., to achieve the effects of ensuring normal heat exchange, reducing processing costs, and facilitating coking treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

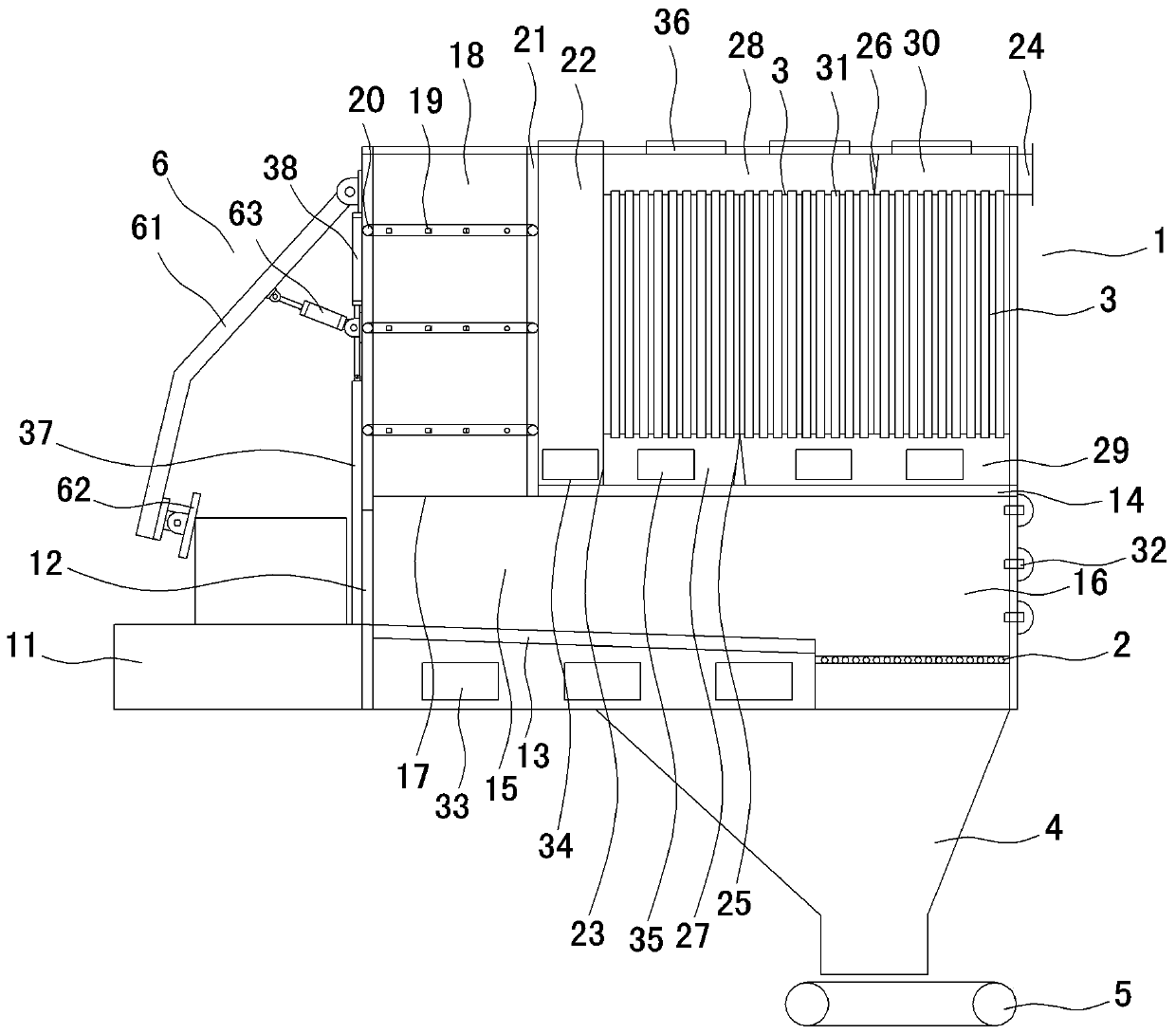

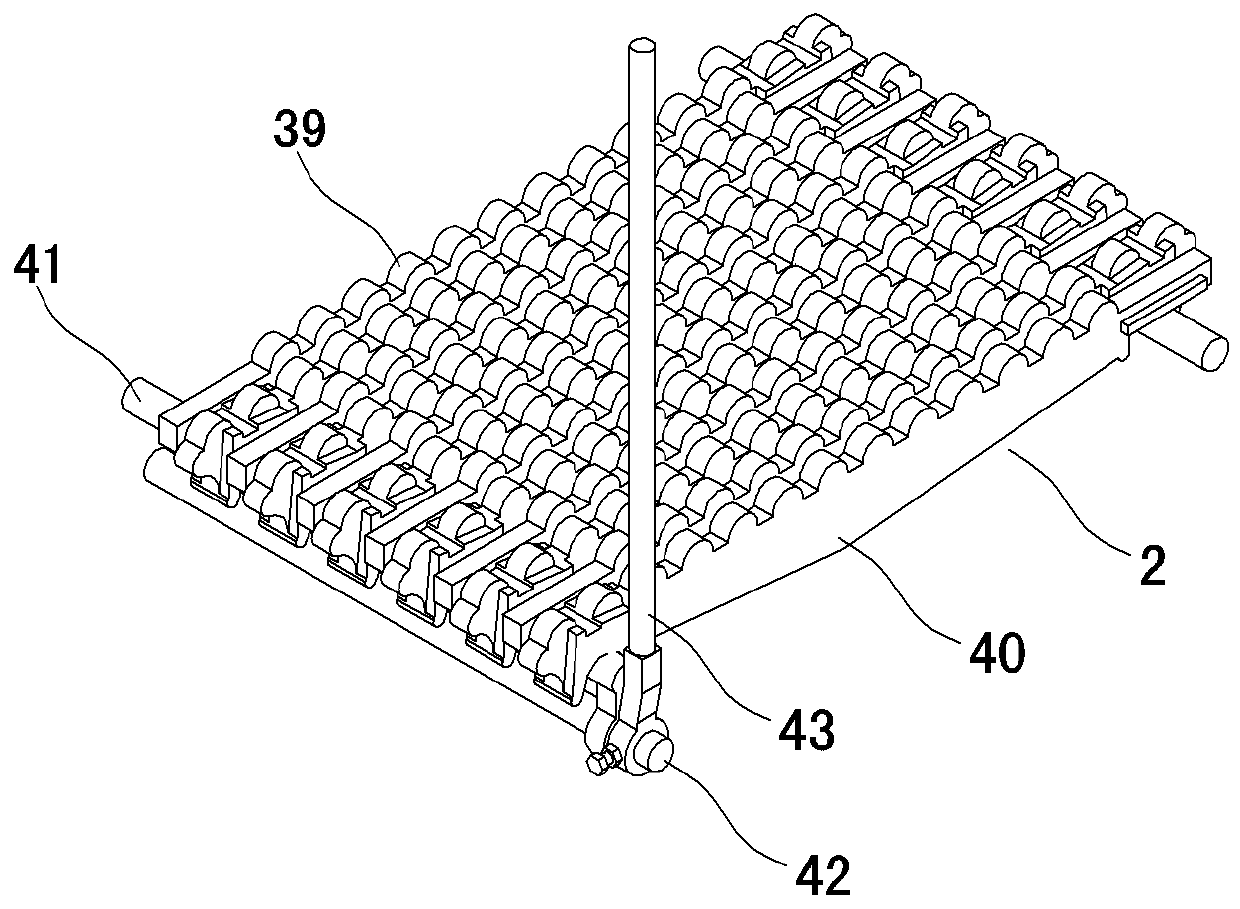

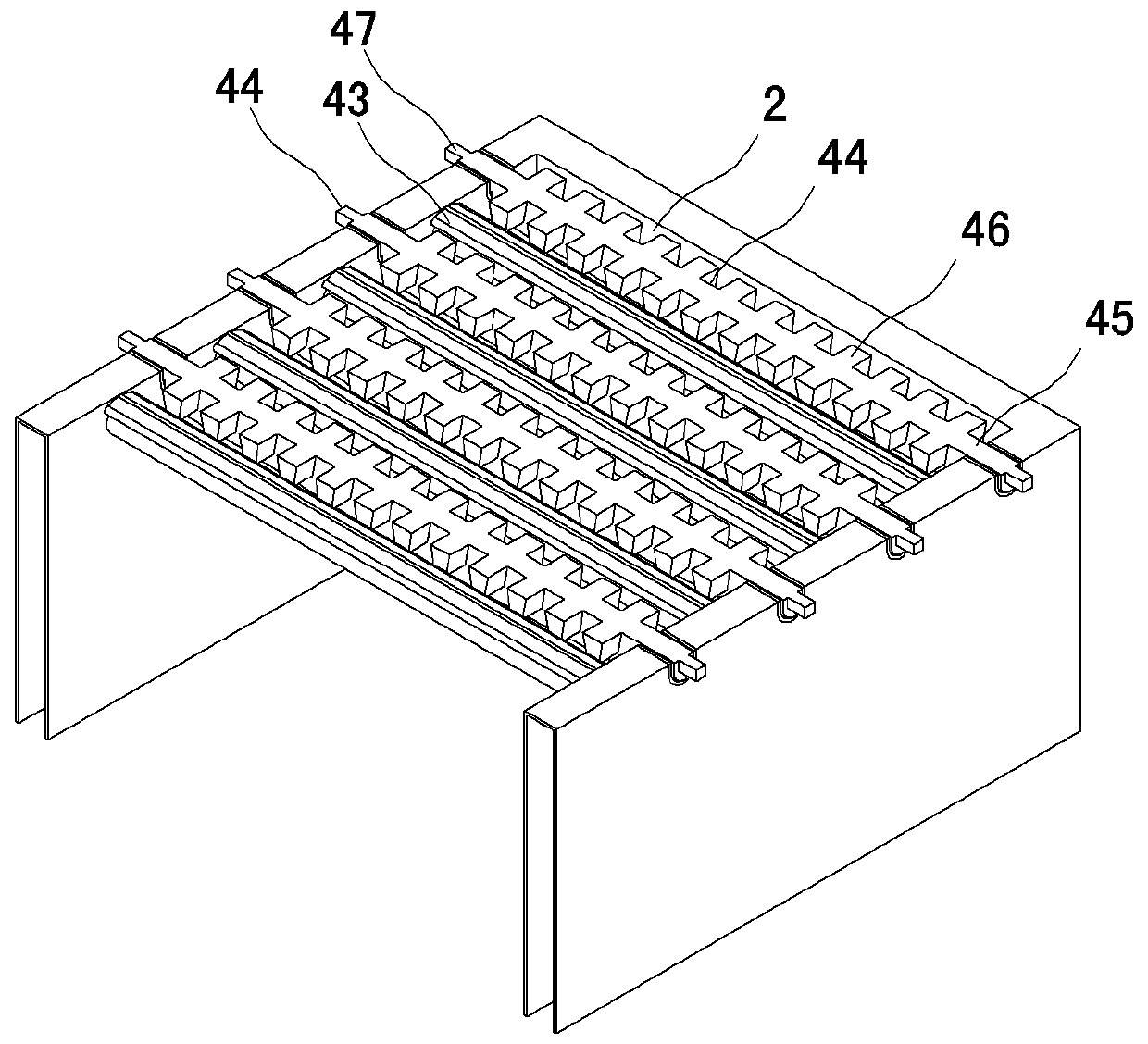

[0009] Such as figure 1 As shown, it comprises a body of furnace 1 with water jackets respectively provided on the side wall and the top wall, a front platform 11 is provided under the front part of the front wall of the body of furnace 1, and a front wall of the body of furnace 1 at the rear position above the front platform 11 is provided with There is a packing entrance 12, and a packing slideway 13 is provided backward from the packing entrance 12 in the furnace body 1, and a coke breaking grate 2 is arranged between the rear part of the packing slideway 13 and the rear wall of the furnace body 1, and the furnace body 1 is provided with a horizontal water jacket 14 located above the bale chute 13 and the coke-breaking grate 2, the primary combustion chamber 15 is formed between the horizontal water jacket 14 and the bale chute 13, and the primary combustion chamber 15 is formed between the coke-breaking grate 2. The coke-breaking combustion chamber 16, the front part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com