Lithium-rich manganese-based Electrode material and preparation method thereof

A lithium-rich manganese-based, positive electrode technology, applied in the direction of positive electrodes, battery electrodes, lithium batteries, etc., can solve the problems of voltage attenuation, poor rate and cycle performance, and low Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

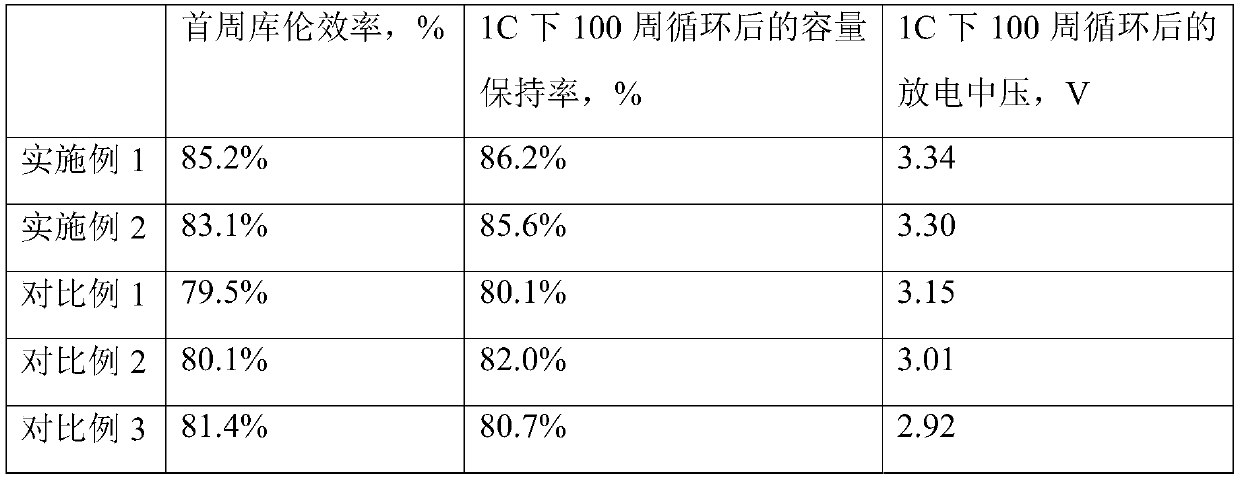

Embodiment 1

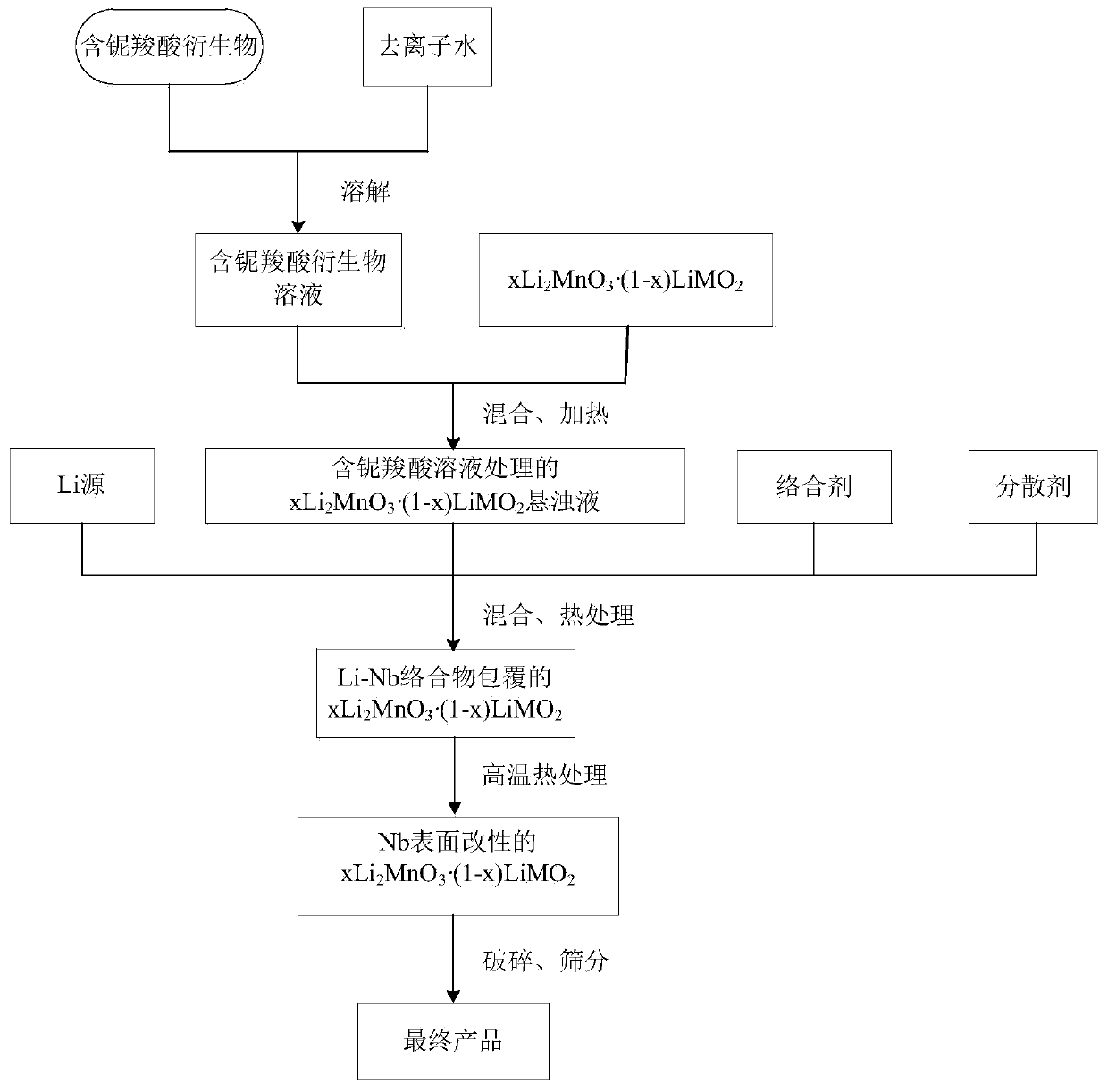

[0027] Preparation method of lithium-rich manganese-based positive electrode material,

[0028] (1) Dissolve niobium oxalate in deionized water to prepare a solution with a pH of 1;

[0029] (2) Mix the lithium-rich manganese-based material with the ammonia niobium oxalate solution, stir and heat to 60°C to form a suspension; the amount of ammonium niobate oxalate added is LMR (0.5Li 2 MnO 3 ·0.5LiNi 1 / 3 Co 1 / 3 Mn 1 / 3 O 2 ) 2wt% of material mass;

[0030] (3) Lithium nitrate, EDTA and dimethyl ether are added to the above suspension in a mass ratio of 1:1:0.1, and heated at 60°C for 10 hours to form a lithium-rich manganese-based material coated with a Li-Nb precursor;

[0031] (4) The lithium-rich manganese-based material coated with the Li-Nb precursor was calcined at 900° C. for 5 hours, and the calcined manganese-based positive electrode material was crushed to 200 mesh.

Embodiment 2

[0033] Preparation method of lithium-rich manganese-based positive electrode material,

[0034] (1) Dissolve ammonium niobium oxalate in deionized water to prepare a solution with a pH of 2;

[0035] (2) Mix the lithium-rich manganese-based material with ammonia niobium oxalate solution, stir and heat to 80°C to form a suspension; the amount of ammonium niobate oxalate added is LMR (0.5Li 2 MnO 3 ·0.5LiNi 1 / 3 Co 1 / 3 Mn 1 / 3 O 2 ) 1wt% of material mass;

[0036] (3) Add the lithium source, complexing agent and dispersant to the above suspension in a mass ratio of 1:2:0.3, and heat at 95°C for 2h to form a lithium-rich manganese-based material coated with Li-Nb precursor ;

[0037] (4) The lithium-rich manganese-based material coated with the Li-Nb precursor obtained in step (3) is calcined at 600° C. for 12 hours, and the calcined lithium-rich manganese-based positive electrode material is crushed to 300 mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com