High-stability TiO2 nanobelt-RGO-porous carbonitride composite photocatalyst, and preparation method thereof

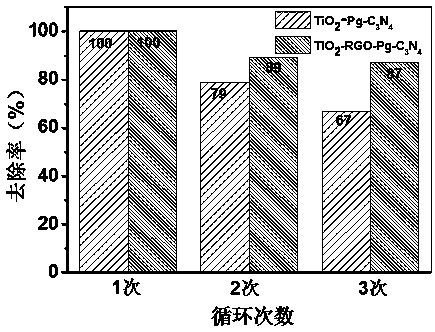

A high-stability nanobelt technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low catalytic activity improvement ratio and ternary composite material stability to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

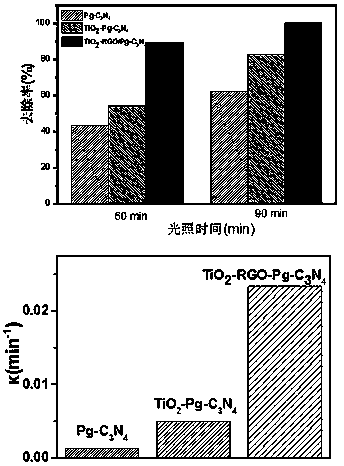

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

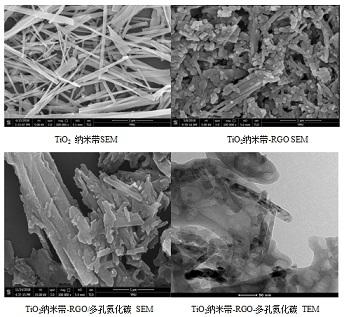

[0028] (1) In the first step, first weigh 5 g of P25 and suspend it in 25 mL of 10 M NaOH aqueous solution, stir for 1 h, transfer to a hydrothermal reaction kettle, stir at 400 rpm, 180 o C reacted in an oil bath for 72 h, cooled, washed with water to pH = 7, then washed with 1 M HCl solution for 1 h, filtered and washed 3 times with water, and dried at 50 for 24 h to obtain TiO 2 nanobelt;

[0029] (2) In the second step, accurately pipette 1mL of a 2mg / mL graphene oxide solution (the volume ratio of water and ethanol is 2:1 as a mixed solvent), and then add 29mL of a mixed solvent of water and ethanol (V water: V ethanol = 2:1), sonicated for 0.5 h, and 0.2 g TiO was added under vigorous stirring 2 Nanobelts were ultrasonically dispersed for 10 min, stirred at room temperature for 2 h, and then the suspension was transferred to a polytetrafluoroethylene high-temperature and high-pressure reactor at 220 o C for 7 h, naturally cooled to room temperature, centrifuged, washed...

Embodiment 2

[0034] (1) In the first step, first weigh 5 g of P25 and suspend it in 25 mL of 10 M NaOH aqueous solution, stir for 1 h, transfer to a hydrothermal reaction kettle, stir at 400 rpm, 180 o C reacted in an oil bath for 72 h, cooled, washed with water to pH = 7, then washed with 1 M HCl solution for 1 h, filtered and washed 3 times with water, and dried at 50 for 24 h to obtain TiO 2 nanobelt;

[0035] (2) In the second step, accurately pipette 1mL of a 2mg / mL graphene oxide solution (the volume ratio of water and ethanol is 2:1 as a mixed solvent), and then add 29mL of a mixed solvent of water and ethanol (V water: V ethanol = 2:1), sonicated for 0.5 h, and 0.2 g TiO was added under vigorous stirring 2 Nanobelts were ultrasonically dispersed for 10 min, stirred at room temperature for 2 h, and then the suspension was transferred to a polytetrafluoroethylene high-temperature and high-pressure reactor at 220 o C for 7 h, naturally cooled to room temperature, centrifuged, washed...

Embodiment 3

[0040] (1) In the first step, first weigh 5 g of P25 and suspend it in 25 mL of 10 M NaOH aqueous solution, stir for 1 h, transfer to a hydrothermal reaction kettle, stir at 400 rpm, 180 o C reacted in an oil bath for 72 h, cooled, washed with water to pH = 7, then washed with 1 M HCl solution for 1 h, filtered and washed 3 times with water, and dried at 50 for 24 h to obtain TiO 2 nanobelt;

[0041] (2) In the second step, accurately pipette 5mL of 2mg / mL graphene oxide (the volume ratio of water and ethanol is 2:1 as a mixed solvent) solution, and then add 25mL of a mixed solvent of water and ethanol (V water: V ethanol = 2:1), sonicated for 0.5 h, and 0.5 g TiO was added under vigorous stirring 2 Nanobelts were ultrasonically dispersed for 10 min, stirred at room temperature for 2 h, and then the suspension was transferred to a polytetrafluoroethylene high-temperature and high-pressure reactor at 220 o C for 7 h, naturally cooled to room temperature, centrifuged, washed 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com