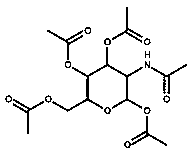

Preparing technology of beta-D-galactosamine pentaacetate

The technology of pentaacetate and galactosamine is applied in the field of preparation technology of β-D-galactosamine pentaacetate, can solve the problems of complicated synthesis process, low purity and high cost, and achieves simple synthesis steps, The effect of high purity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation technology of a kind of β-D-galactosamine pentaacetate that the present invention proposes, comprises the following steps,

[0021] S1, D-galactose and vinyl acetate are used as raw materials, anhydrous sodium acetate is used as a catalyst, and a mixed solvent of toluene and benzene is used as a reaction solvent. The raw materials and reaction solvent are placed in a reaction kettle, and the reaction temperature is controlled at 40°C. The reaction time was 15 minutes, distilled under reduced pressure, filtered, recovered the filtrate, washed the filtrate with ethanol, and vacuum-dried to constant weight to obtain β-D-galactose pentaacetate;

[0022] S2, put the β-D-galactose pentaacetate obtained in S1 into the reaction kettle, then add thioacetamide, then add an organic solvent, control the temperature at 22°C, react for 45min, stop heating, and obtain a mixed solution A;

[0023] S3, the mixed solution A is extracted with an extraction solvent, washed...

Embodiment 2

[0025] The preparation technology of a kind of β-D-galactosamine pentaacetate that the present invention proposes, comprises the following steps,

[0026] S1, D-galactose and vinyl acetate are used as raw materials, anhydrous sodium acetate is used as a catalyst, and a mixed solvent of toluene and benzene is used as a reaction solvent. The raw materials and reaction solvent are placed in a reaction kettle, and the reaction temperature is controlled at 50°C. The reaction time is 20 minutes, distilled under reduced pressure, filtered, recovered the filtrate, washed the filtrate with ethanol, and dried in vacuum to constant weight to obtain β-D-galactose pentaacetate;

[0027] S2, put the β-D-galactose pentaacetate obtained in S1 into the reaction kettle, then add thioacetamide, then add an organic solvent, control the temperature at 25°C, react for 55min, stop heating, and obtain a mixed solution A;

[0028] S3, the mixed solution A is extracted with an extraction solvent, wash...

Embodiment 3

[0030] The preparation technology of a kind of β-D-galactosamine pentaacetate that the present invention proposes, comprises the following steps,

[0031] S1, D-galactose and vinyl acetate are used as raw materials, anhydrous sodium acetate is used as a catalyst, and a mixed solvent of toluene and benzene is used as a reaction solvent. The raw materials and the reaction solvent are placed in a reaction kettle, and the reaction temperature is controlled at 55°C. The reaction time was 35 minutes, distilled under reduced pressure, filtered, recovered the filtrate, washed the filtrate with ethanol, and vacuum-dried to constant weight to obtain β-D-galactose pentaacetate;

[0032] S2, put the β-D-galactose pentaacetate obtained in S1 into the reaction kettle, then add thioacetamide, then add an organic solvent, control the temperature at 28°C, react for 75min, stop heating, and obtain a mixed solution A;

[0033] S3, the mixed solution A is extracted with an extraction solvent, wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com