Proportioning scheme of color ribbon colorant with good coloring performance

A technology of coloring performance and pigments, applied in inks, household appliances, applications, etc., can solve the problems of difficult storage for a long time, hard hand feeling, uneven cutting edges, etc., to prolong storage time, improve coloring performance, and select materials. The effect of matching science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

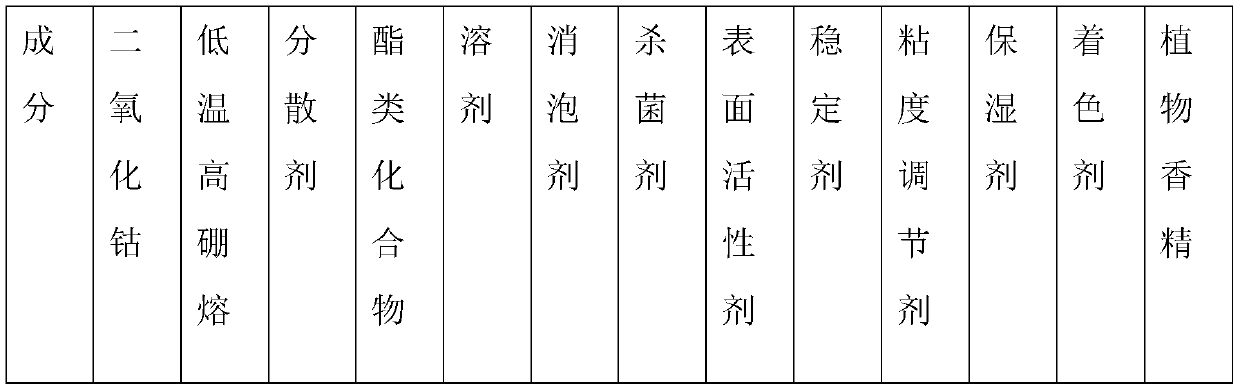

[0041] Example 1, a coloring material ratio scheme for a ribbon with good coloring performance, including components in percentage of raw materials: 32% of cobalt dioxide, 6% of low-temperature high-boron frit, 12% of dispersant, 16% of ester compound, 25% solvent, 0.6% defoamer, 0.6% bactericide, 0.6% surfactant, 0.6% stabilizer, 5% viscosity regulator, 0.5% moisturizer, 0.6% colorant, 0.5% plant essence.

[0042]

[0043]

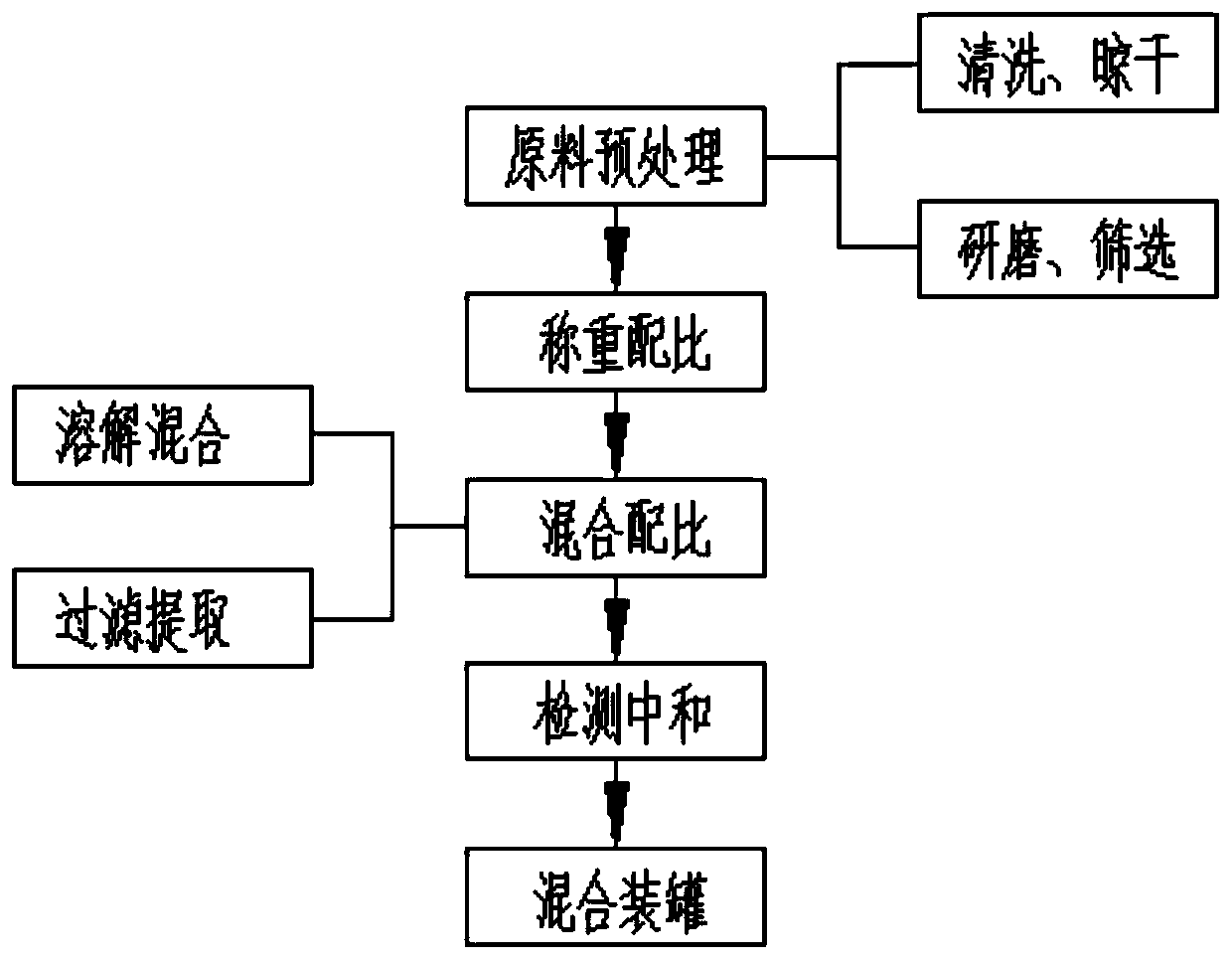

[0044] Include the following steps:

[0045] Step 1. Raw material pretreatment

[0046] S1: Select cobalt dioxide and low-temperature high-boron frit, wash and dry at room temperature;

[0047] S2: The cobalt dioxide and low-temperature high-boron frit obtained in S1 are respectively crushed and ground with a crusher and a grinder, and 2000-mesh cobalt dioxide powder and low-temperature high-boron frit powder are obtained by screening, and canned for later use ;

[0048] Step 2. Weighing ratio

[0049] Use a weighing device to weigh 32% of cobal...

Embodiment 2

[0057] Example 2, a colorant ratio scheme for a ribbon with good coloring performance, including components in percentage of raw materials: 28% of cobalt dioxide, 7% of low-temperature high-boron frit, 6% of dispersant, 10% of ester compound, 34% solvent, 0.8% defoamer, 0.8% bactericide, 0.8% surfactant, 0.8% stabilizer, 10% viscosity regulator, 0.5% moisturizer, 0.8% colorant, 0.5% plant essence.

[0058]

[0059] Include the following steps:

[0060] Step 1. Raw material pretreatment

[0061] S1: Select cobalt dioxide and low-temperature high-boron frit, wash and dry at room temperature;

[0062]S2: The cobalt dioxide and low-temperature high-boron frit obtained in S1 are respectively crushed and ground with a crusher and a grinder, and 2000-mesh cobalt dioxide powder and low-temperature high-boron frit powder are obtained by screening, and canned for later use ;

[0063] Step 2. Weighing ratio

[0064] Use a weighing device to weigh 28% of cobalt dioxide powder and 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com