Water-based low-temperature thermal mounting coating and preparation method thereof

A low-temperature heat and water-based technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of cold lamination film and material wrinkle deformation, earthworm-like arching of cold lamination film layer, poor adhesion and wrinkling, etc. Improve production drying speed, high lamination fastness, good light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to better explain the present invention, it will be further described in conjunction with the following specific examples, but the present invention is not limited to the specific examples.

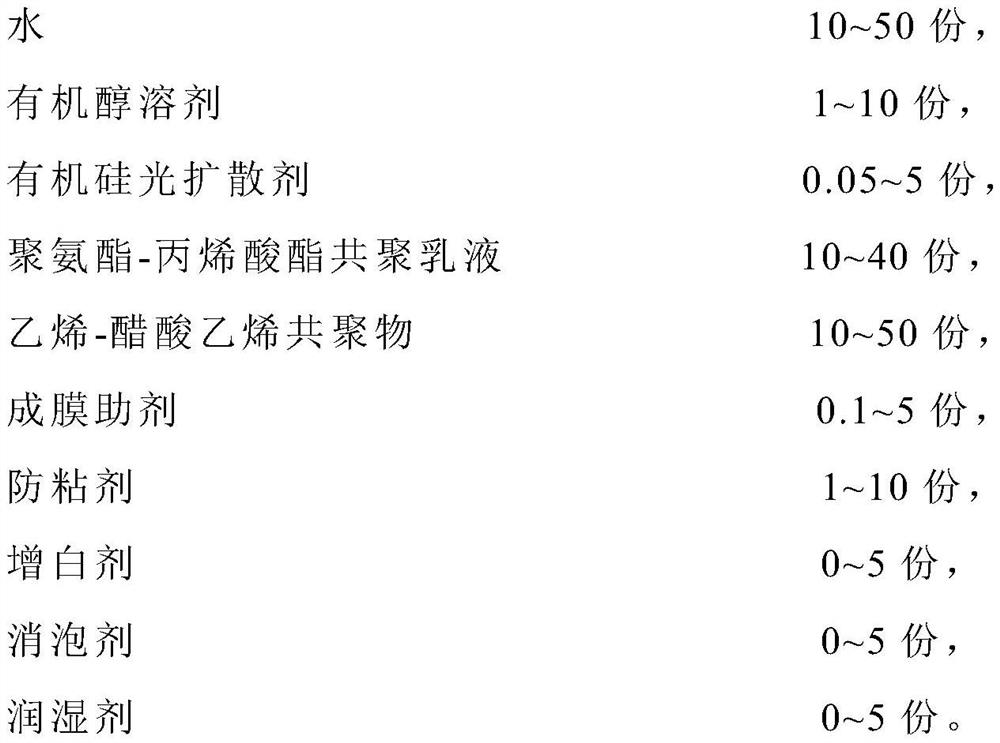

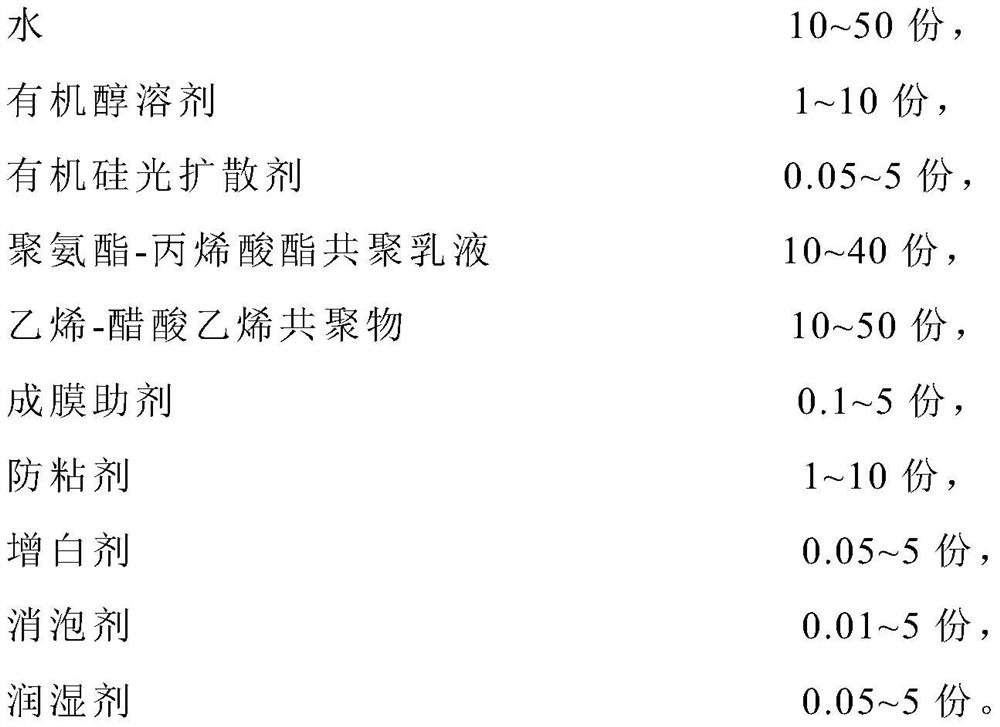

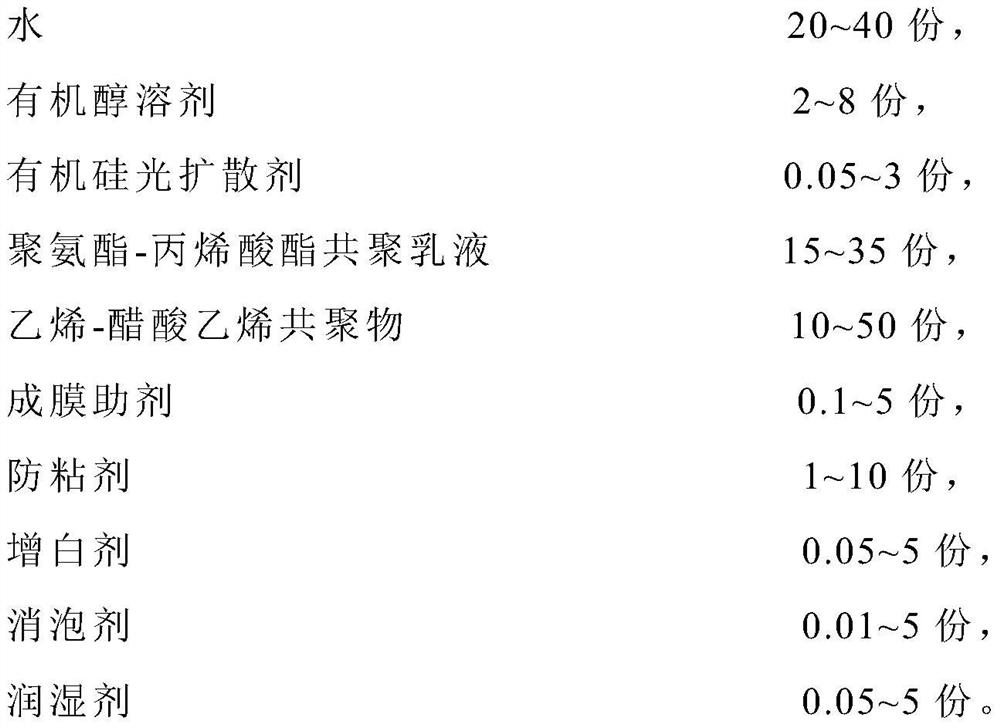

[0062] Table 1: The formula of embodiment 1-4 and every square wet glue amount (g / m 2 ).

[0063]

[0064]

[0065] The amount of wet glue per square meter refers to the amount of raw materials contained in the glue coated on the substrate per square meter.

[0066] The spherical silicone light diffusing agent is provided by Shanghai Jinghong Chemical Technology Co., Ltd., the model is JIAYID750. Polyurethane-acrylate copolymer emulsion was provided by Clariant Chemical (China) Co., Ltd., model ADC616. Ethylene-vinyl acetate copolymer was provided by Guangxi Guangwei Chemical Co., Ltd., model GW-707. The anti-scratch wax is provided by Beijing Tianhengjian Technology Development Co., Ltd., the model is THK-F4. 1,2-bis(5-methyl-2-benzoxazolyl)-ethylene is provided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com