Aqueous peelable coating and preparation method thereof

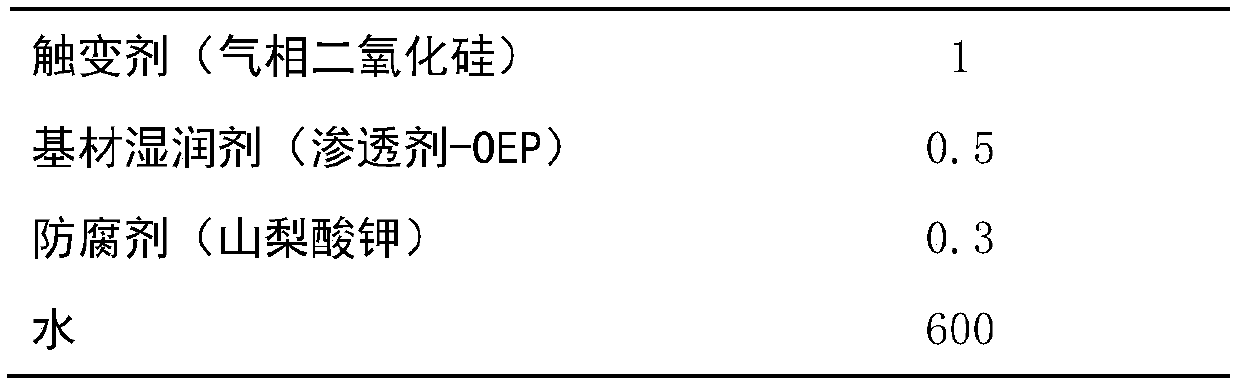

A water-based, coating technology, used in antifouling/underwater coatings, conductive coatings, amylose/amylopectin derivative coatings, etc., can solve problems such as environmental pollution and waste of resources, and achieve high film-forming strength and durability. Excellent antistatic properties and oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A preparation method of water-based peelable coating, comprising the steps of:

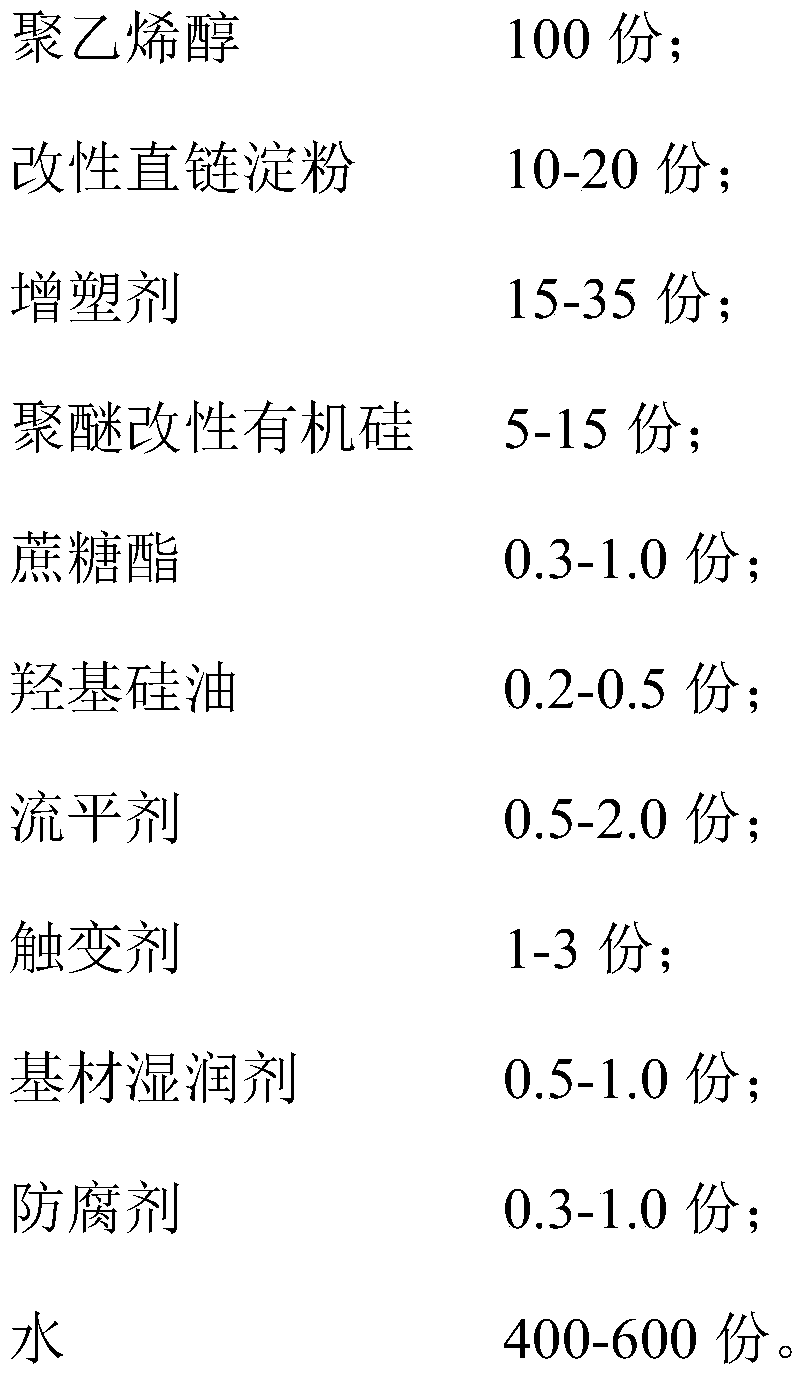

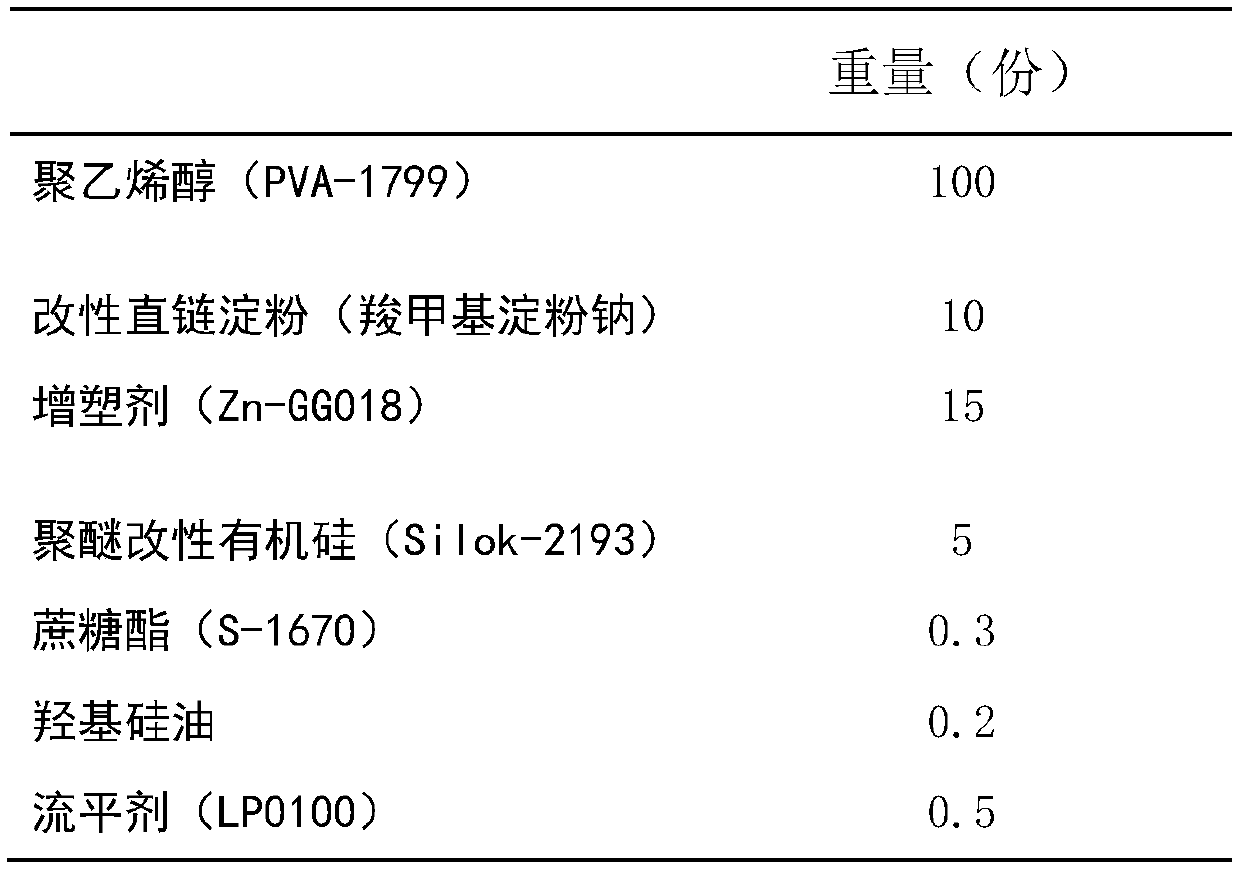

[0049] (1) Mix polyvinyl alcohol, modified amylose, plasticizer, polyether modified silicone, sucrose ester, hydroxyl silicone oil, leveling agent, thixotropic agent, substrate wetting agent, preservative and water, Obtain mixed liquor; The relation of each raw material component that uses described in embodiment 1 is shown in following table 1;

[0050] (2) Under the stirring state that the rotating speed is 60 rev / min, the mixed solution described in step (1) is heated up and heat-treated, the temperature of the heat treatment is 95° C., and the time of the heat treatment is 2 hours, and then the temperature is lowered to At room temperature, the water-based peelable coating was obtained. The film performance indicators of the water-based peelable coating prepared in Example 1 after film formation are shown in Table 2 below.

[0051] Table 1

[0052]

[0053]

[0054] Table 2

...

Embodiment 2

[0057] A preparation method of water-based peelable coating, comprising the steps of:

[0058] (1) Mix polyvinyl alcohol, modified amylose, plasticizer, polyether modified silicone, sucrose ester, hydroxyl silicone oil, leveling agent, thixotropic agent, substrate wetting agent, preservative and water, Obtain mixed solution; The relation of each raw material component that uses described in embodiment 2 is shown in following table 3;

[0059] (2) Under the stirring state that the rotating speed is 120 rev / min, the mixed solution described in step (1) is heated up, and heat-treated, the temperature of the heat-treatment is 98° C., and the time of the heat-treatment is 4 hours, and then the temperature is lowered to At room temperature, the water-based peelable coating was obtained. The film performance indicators of the water-based peelable coating prepared in Example 2 after film formation are shown in Table 4 below.

[0060] table 3

[0061]

[0062]

[0063] Table 4...

Embodiment 3

[0066] A preparation method of water-based peelable coating, comprising the steps of:

[0067] (1) Mix polyvinyl alcohol, modified amylose, plasticizer, polyether modified silicone, sucrose ester, hydroxyl silicone oil, leveling agent, thixotropic agent, substrate wetting agent, preservative and water, Obtain mixed liquor; The relation of each raw material component that embodiment 3 uses is shown in following table 5.

[0068] (2) Under the stirring state that the rotating speed is 100 rev / min, the mixed liquid described in step (1) is heated up, and heat-treated, the temperature of heat-treatment is 96 ℃, the time of heat-treatment is 2.5 hours, then cools down to At room temperature, the water-based peelable coating was obtained. The film performance indicators of the water-based peelable coating prepared in Example 3 after film formation are shown in Table 6 below.

[0069] table 5

[0070]

[0071] Table 6

[0072]

[0073]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com