Preparation method of controllable long-acting slow-release scale inhibitor capsule

The technology of scale inhibitor and capsule is applied in the field of preparation of controllable long-acting slow-release scale inhibitor capsule to achieve the effect of prolonging the protective effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing a controllable long-acting slow-release scale inhibitor capsule includes the following steps:

[0041] Step 1: Load scale inhibitor

[0042] Load the scale inhibitor solution with a weight percentage concentration of 30-50% and the carrier in a weight ratio of 1:1 to 1:2 under vacuum and negative pressure;

[0043] Step 2: Kneading and drying

[0044] Transfer the scale inhibitor loaded in step 2 to the kneader for kneading for 25 to 35 minutes, and vacuum dry the loaded sample after the treatment;

[0045] Step 3: Prepare the carboxymethyl cellulose solution

[0046] Disperse carboxymethyl cellulose with a concentration of 10% by weight in water and heat to 75-85°C for 50-70 minutes to form a uniform and viscous solution;

[0047] Step 4: Evenly mix the polymer and the loaded sample

[0048] Weigh the loaded sample processed in step 2 and the carboxymethyl cellulose solution prepared in step 3 in a mass ratio of 7:3-9:1, and knead it in a kneader for 20-40 mi...

Embodiment 2

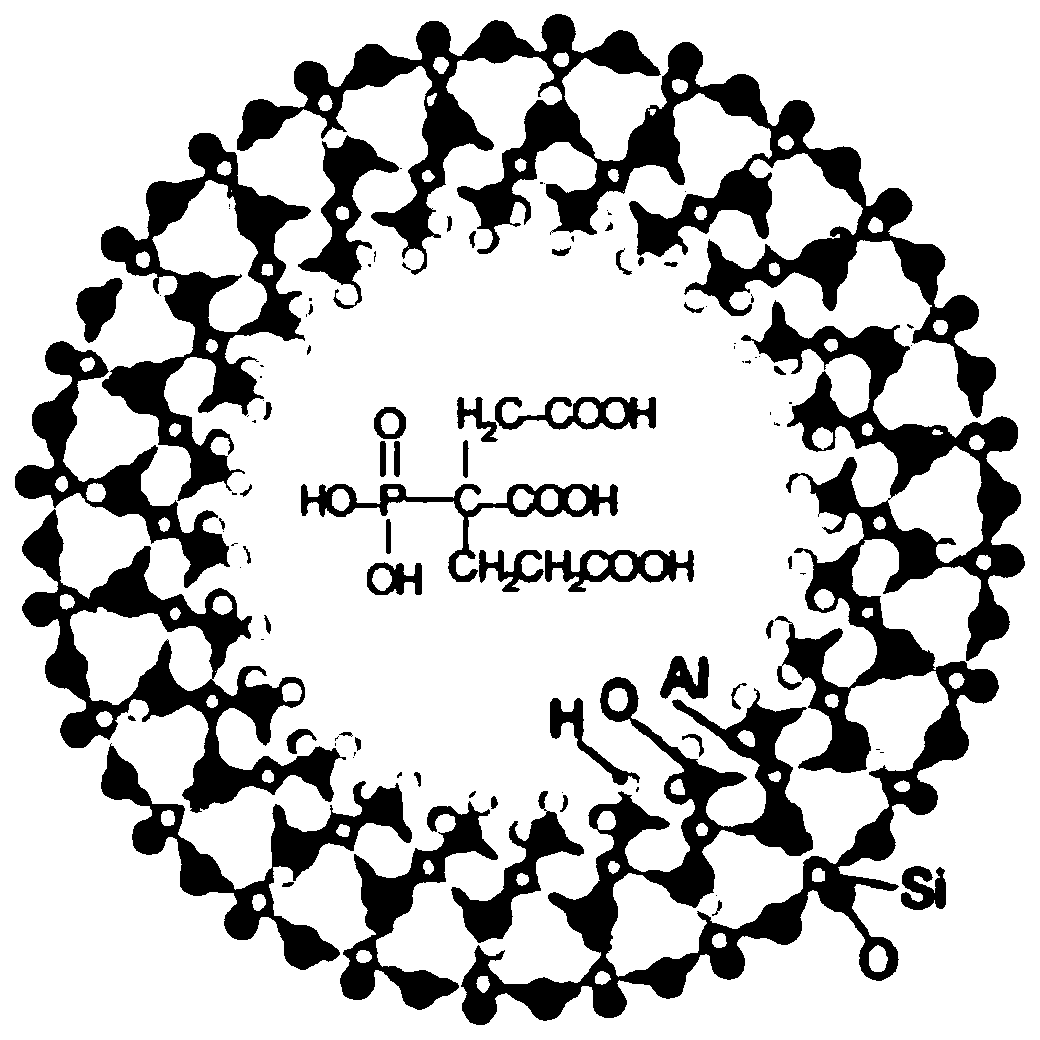

[0060] A method for preparing a controllable and long-acting slow-release scale inhibitor capsule is different from the first embodiment in that the scale inhibitor in the first step is an organic phosphine scale inhibitor.

[0061] Preferably, the organic phosphorus scale inhibitor is amino trimethylene phosphonate, ethylene diamine tetramethylene phosphonic acid, hydroxy ethylidene diphosphonate, 12-phosphonic acid butane-1,2,4-tri Carboxylic, 2-hydroxyphosphonoacetic acid, hexamethylenediamine tetramethylene phosphonic acid or hydrolyzed polymaleic anhydride.

[0062] In actual use, organic phosphine scale inhibitors not only have better resistance to formation water with high salinity, but also have multiple -COOH and -OH, which are used in combination with inorganic tubular fillers such as natural halloysite nanotubes, porous Zeolite etc. are fully assembled.

Embodiment 3

[0064] A method for preparing controllable and long-acting slow-release scale inhibitor capsules, which is different from Example 1 in that the diameter of the granular capsules in step 5 is 1 to 5 mm; the extrusion granulator used is Polymer extrusion granulator.

[0065] In actual use, the diameter of the granular capsule is chosen to match the annular gap as much as possible. The main reason is that the one-side spacing of the oil sleeve annulus is generally more than 25mm; at the same time, when tools are provided outside the tubing, the annulus gap is generally more than 7mm. At this time, the diameter of the granular capsule is less than 1 / 2 of 7mm, that is, 1~3mm is best.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com