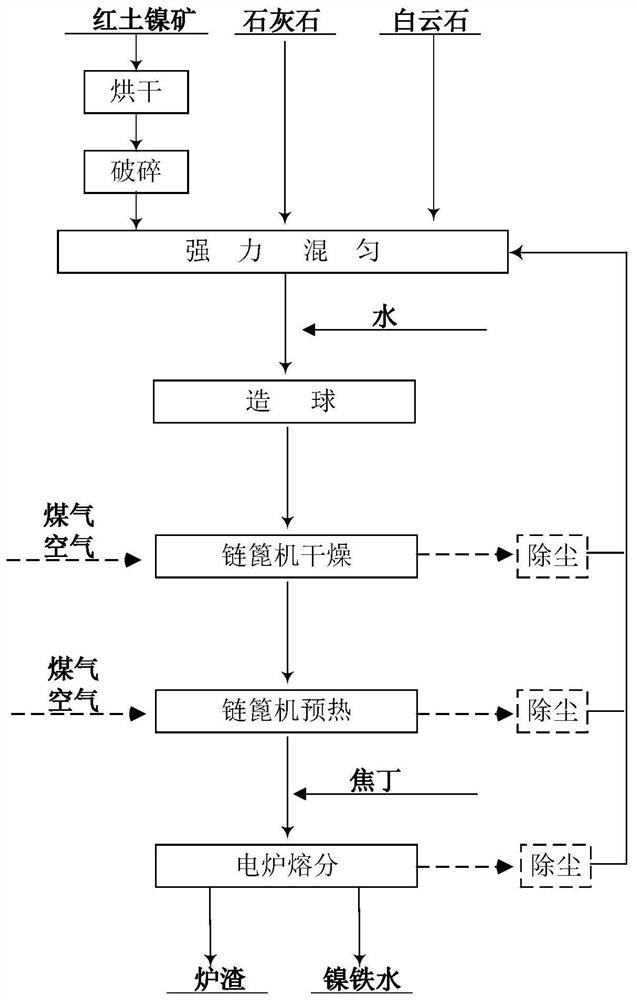

A method for producing high-nickel molten iron by chain grate machine preheating-electric furnace melting for low-grade laterite nickel ore

A technology of lateritic nickel ore and chain grate machine, which is applied in the field of metallurgy, can solve problems such as unproposed solutions, achieve the effects of large shrinkage and strength changes, low production efficiency, and prevent dust generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Dry the low-grade lateritic nickel ore to 13.5% water content, crush it, add a certain amount of limestone and dolomite, and adjust the MgO / SiO 2 The ratio is 0.45, and the alkalinity is 0.2; then the laterite nickel ore, limestone and dolomite are mixed in an intensive mixer, and the stirring speed is 1200rpm during the intensive mixing process, and the stirring time is 75 seconds; The pelletizing water is 16.5%, the pelletizing time is 12min, the average particle size is 15mm, the falling strength of the obtained green pellets is 4.3 times / 0.5m, and the compressive strength of the pellets is 11.3N / piece. The ball burst temperature was 320°C. The green balls were dried at 300°C for 7 minutes and preheated at 850°C for 10 minutes on a grate machine (the height of the green ball layer was 90mm), and the compressive strength of the obtained preheated pellets was 610N / piece. After preheating, the red-hot pellets with a temperature of about 850°C are directly put into the ...

Embodiment 2

[0061] Dry the low-grade lateritic nickel ore to 14.7% water content, crush it, add a certain amount of limestone and dolomite, and adjust the MgO / SiO 2 The ratio is 0.55, and the alkalinity is 0.3; then the laterite nickel ore, limestone and dolomite are mixed in an intensive mixer, and the stirring speed is 1700rpm during the intensive mixing process, and the stirring time is 90 seconds; The pelletizing water is 16.0%, the pelletizing time is 15min, and the average particle size is 15mm. The drop strength of the green pellets obtained is 4.8 times / 0.5m, and the compressive strength of the pellets is 13.2N / piece. The ball burst temperature was 355°C. The green balls were dried at 350°C for 5 minutes and preheated at 900°C for 12 minutes on a grate machine (the height of the green ball layer was 100mm), and the compressive strength of the obtained preheated pellets was 724N / piece. After preheating, the red-hot pellets with a temperature of about 900°C are directly put into th...

Embodiment 3

[0067] Dry the low-grade lateritic nickel ore to a water content of 14.6%, crush it, add a certain amount of limestone and dolomite, and adjust the MgO / SiO 2 The ratio is 0.65, and the alkalinity is 0.4; then the laterite nickel ore, limestone and dolomite are mixed in an intensive mixer, and the stirring speed is 1800rpm during the intensive mixing process, and the stirring time is 90 seconds; The pelletizing water is 16.5%, the pelletizing time is 15min, and the average particle size is 15mm. The drop strength of the green pellets obtained is 4.9 times / 0.5m, and the compressive strength of the pellets is 13.8N / piece. The ball burst temperature was 375°C. The green balls were dried at 350°C for 6 minutes and preheated at 950°C for 15 minutes on a grate machine (the height of the green ball layer was 105mm). The compressive strength of the obtained preheated pellets was 788N / piece. After preheating, the red-hot pellets with a temperature of about 950°C are directly put into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| burst temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com