A Fabry-Perot sensor based on silicon core optical fiber and its preparation and application

A sensor, silicon core technology, applied in the direction of converting sensor output, using optical devices to transmit sensing components, photometry, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

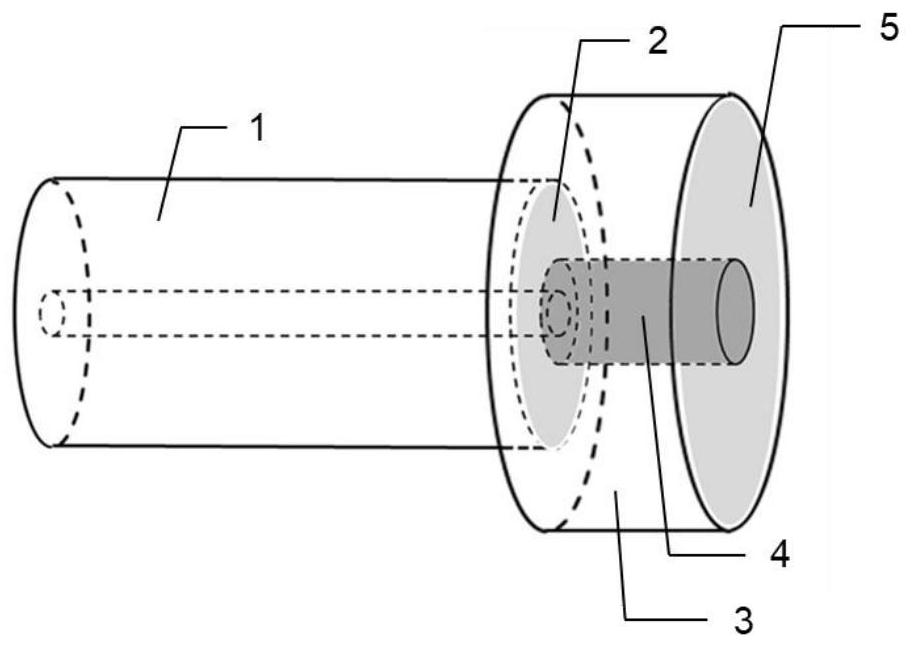

[0033] A Fabry-Perot sensor based on silicon core optical fiber, which consists of ordinary single-mode optical fiber (1), fiber fusion splicing end face (2), silicon core optical fiber cladding (3), silicon core optical fiber core (4) and polished end face (5) Composition, see figure 1 ; The production process is to first fuse the silicon core fiber with the standard single-mode fiber, and then grind and polish the other end of the silicon core fiber to the required length to form a silicon core fiber Fabry-Perot sensor. When the standard single-mode fiber and silicon core fiber are fused together, the fusion end surface is smooth and flat; the cavity length of the silicon core Fabry-Perot cavity ranges from 1 to 600 μm to ensure that the interference spectrum has a high contrast and a large Free Spectrum Range.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com