Method for extracting inclusions in steel by non-aqueous solution electrolysis

An electrolytic extraction and non-aqueous solution technology, which is applied in the field of metal physics research and non-aqueous solution electrolytic extraction of inclusions in steel, can solve the problem of unstable extraction of inclusions, small-sized inclusions that cannot be accurately evaluated, unstable inclusions, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

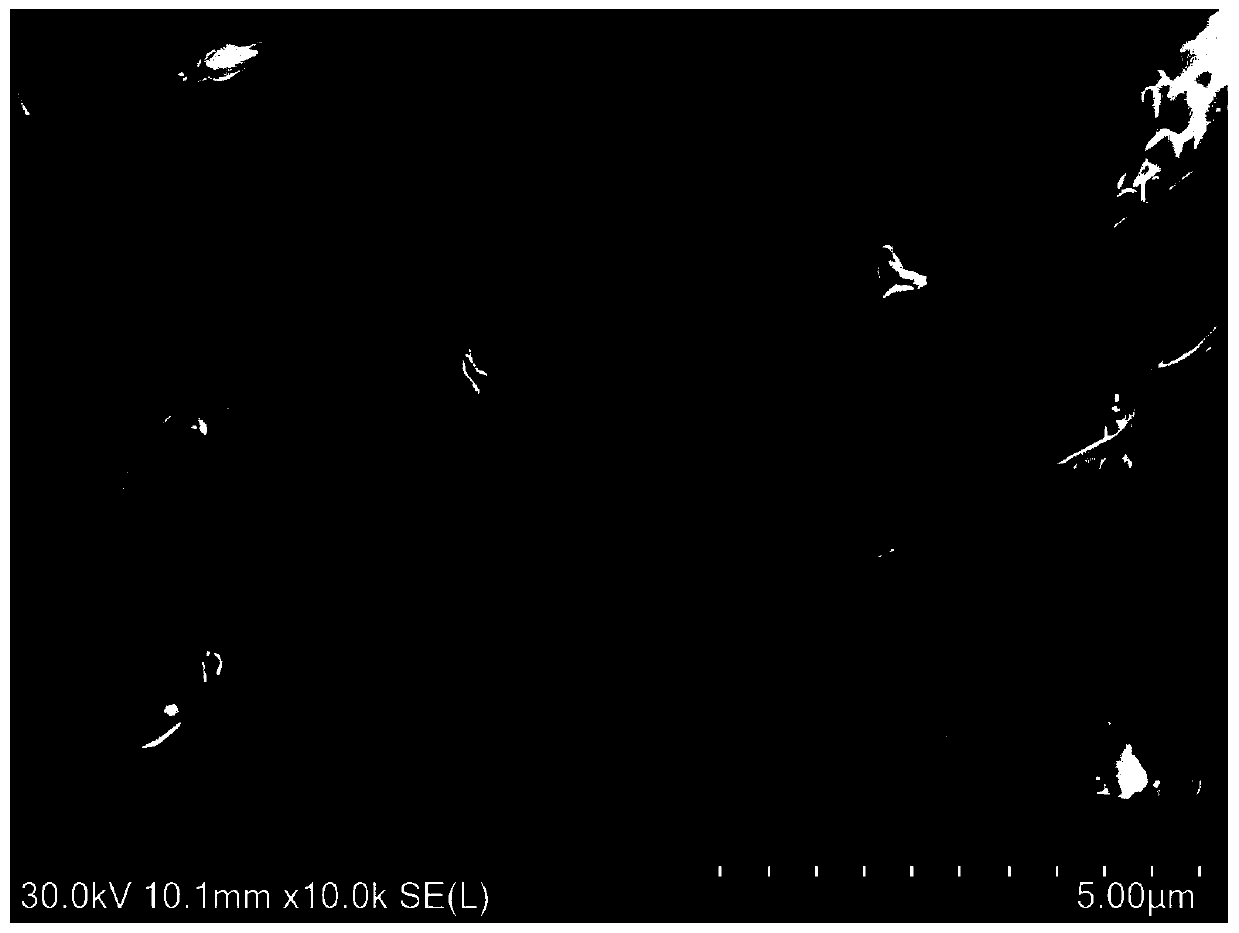

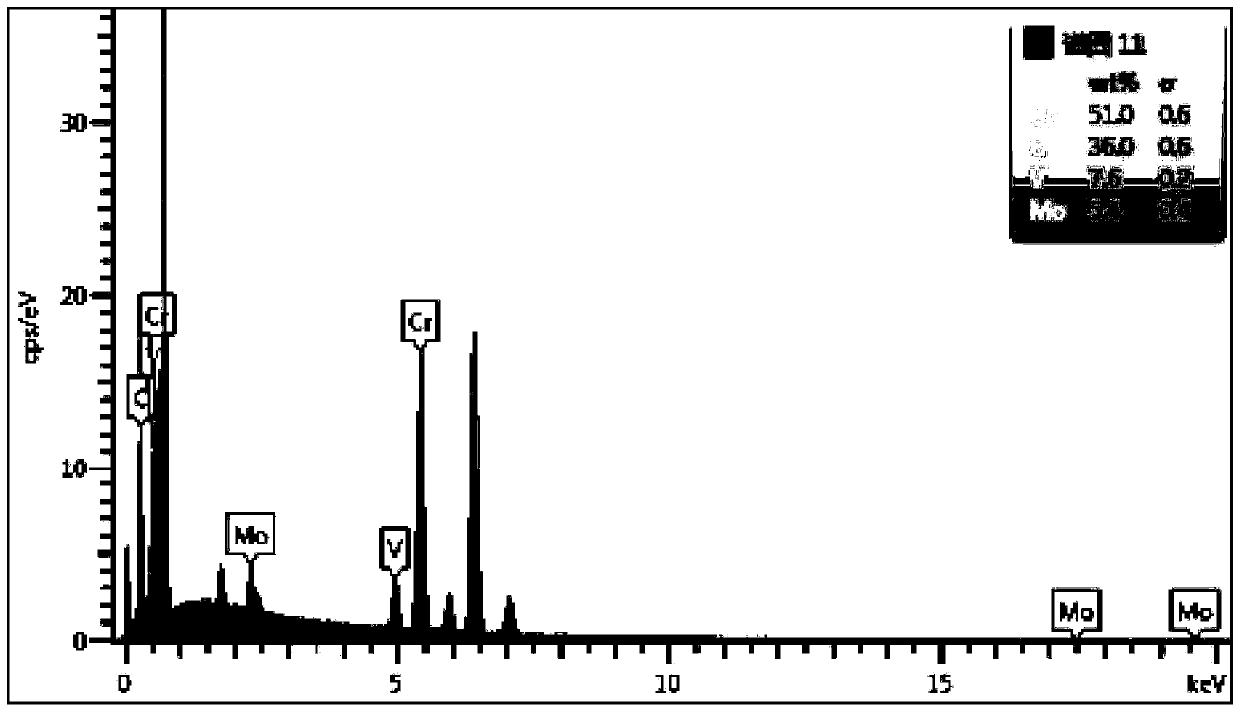

[0034] Example: Extraction of carbides in H13 steel by electrolysis of non-aqueous solution

[0035] Sample preparation: Cut the annealed H13 steel into thin slices of 20×40×5mm, and then polish it with sandpaper until the surface is smooth. After polishing, clean it with absolute ethanol and dry it.

[0036] Preparation of electrolyte: The composition of the electrolyte is: 4.2g tetramethylammonium chloride + 60g acetylacetone + 9g ammonium thiocyanate + 526.8g anhydrous methanol. Pour each substance into a beaker according to the required ratio and stir evenly with a glass rod.

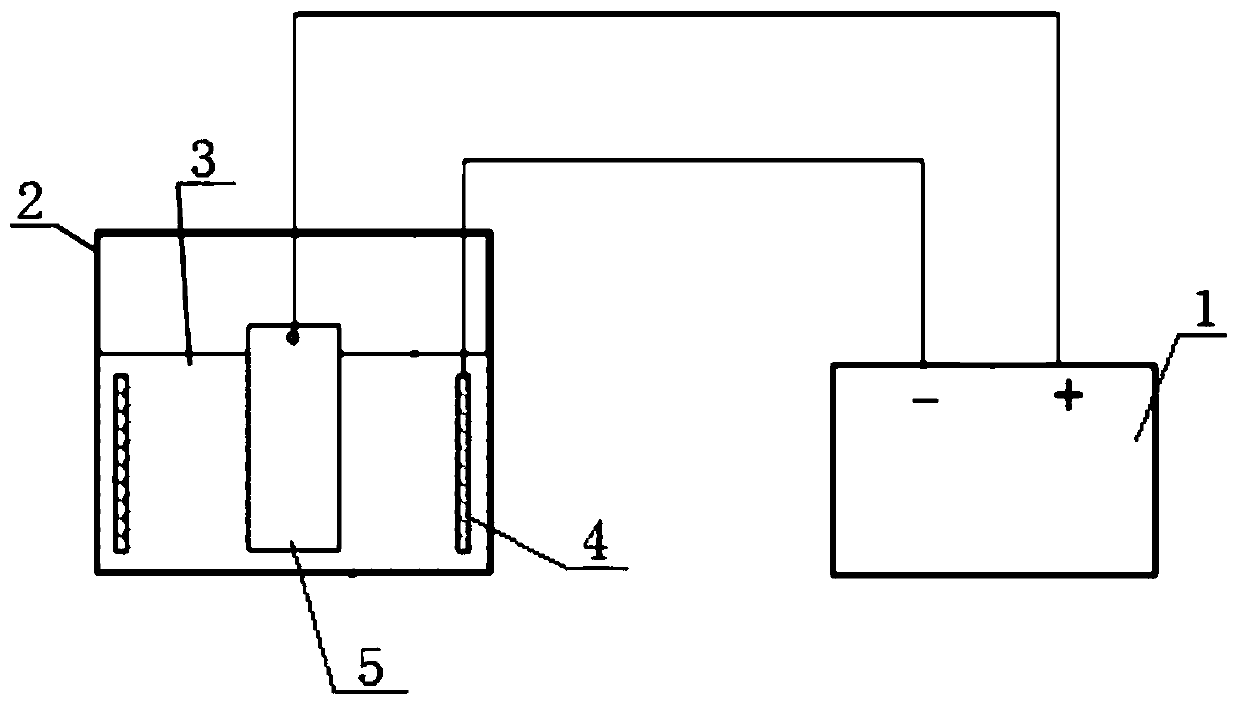

[0037] Electrolysis process: see appendix figure 1 , the electrolysis workstation for non-aqueous solution electrolytic extraction of inclusions in steel includes a DC power supply 1, an electrolytic cell 2, the above electrolyte 3, and a stainless steel film 4; the stainless steel film is connected to the negative pole of the DC power supply, and the H13 steel sample 5 is connected to the positive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com