Lithium battery with long service life

A lithium battery, life-span technology, applied in the direction of secondary batteries, battery pack components, battery boxes/coats, etc., can solve the problems of lithium battery life reduction, high risk, explosion, etc., to ensure safety performance and service life , protection and service life, and the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

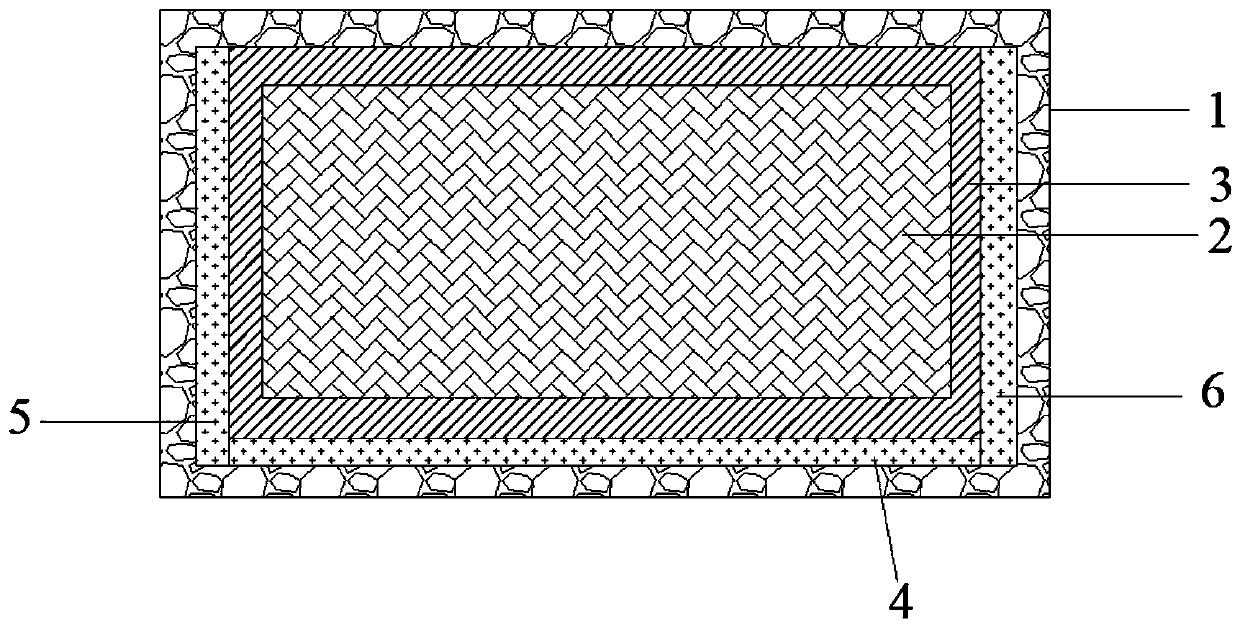

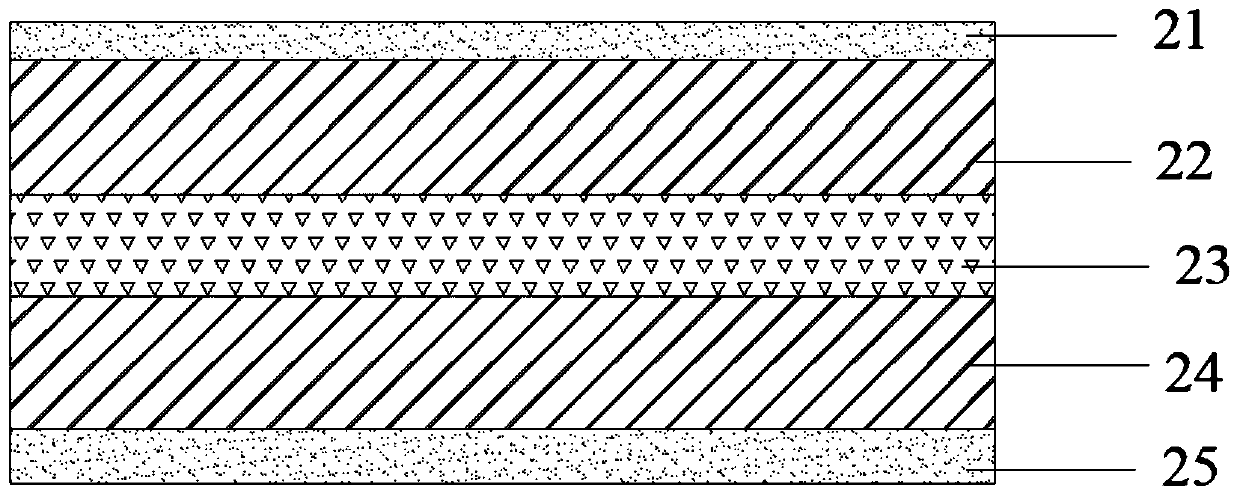

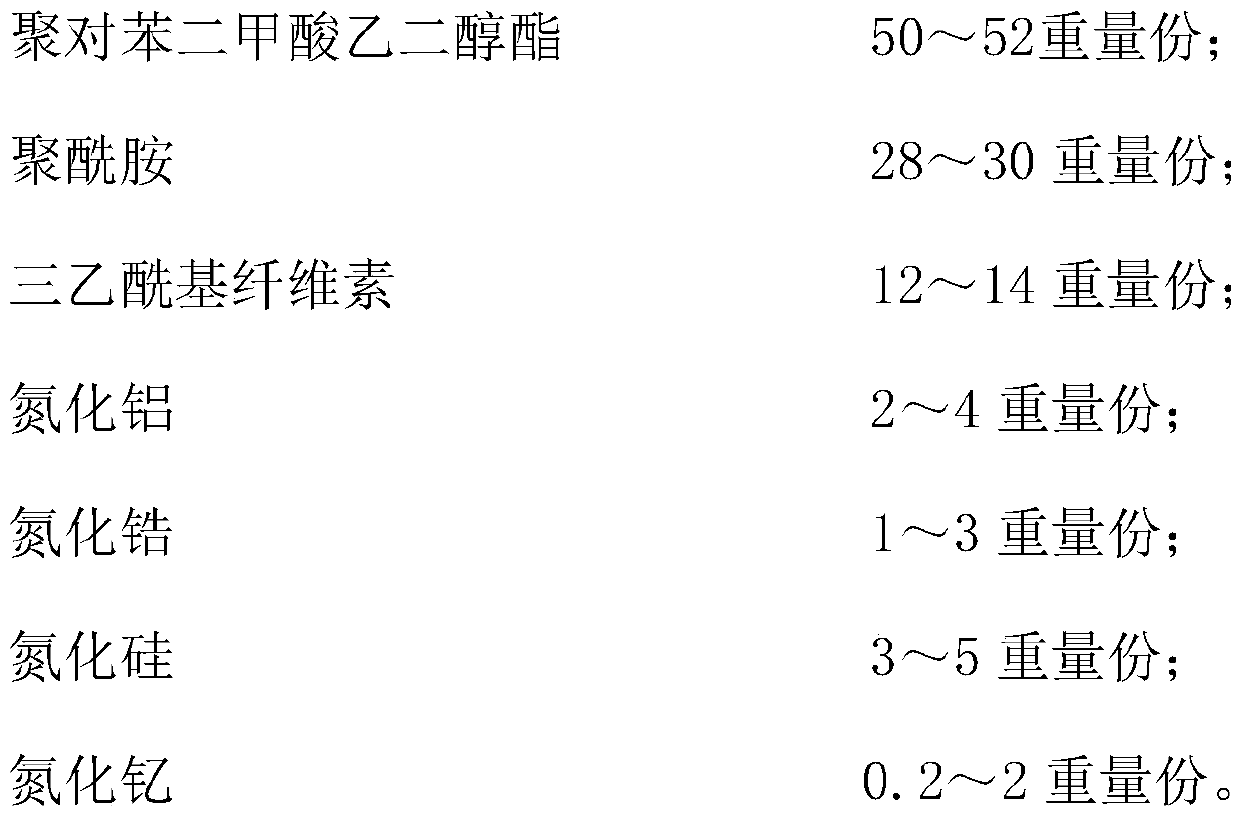

[0037] A long-life lithium battery includes a packaging structure and a lithium battery cell arranged in the packaging structure. The lithium battery cell includes a first current collector, a negative electrode layer, an electrolyte layer, a positive electrode layer and a second current collector; the packaging structure includes the following Parts by weight of material:

[0038]

[0039] The number average molecular weight of polyethylene terephthalate is 10000g / mol; the thickness of the first current collector and the second current collector is 5μm; the thickness of the positive electrode layer is 6μm; the thickness of the electrolyte layer is 0.1μm; An insulating layer is also provided between the core and the packaging structure; the material of the insulating layer is tetrafluoroethylene-hydrocarbon propylene copolymer; the insulating layer and the bottom inner wall of the packaging structure are provided with a first heat dissipation plate; the insulating layer and both s...

Embodiment 2

[0041] A long-life lithium battery, comprising a packaging structure and a lithium battery cell arranged in the packaging structure. The lithium battery cell includes a first current collector, a negative electrode layer, an electrolyte layer, a positive electrode layer and a second current collector; the packaging structure Including the following parts by weight:

[0042]

[0043] The number average molecular weight of polyethylene terephthalate is 12000g / mol; the thickness of the first current collector and the second current collector is 6μm; the thickness of the positive electrode layer is 10μm; the thickness of the electrolyte layer is 2μm; lithium battery cell An insulation layer is also provided between the packaging structure and the insulation layer, and the material of the insulation layer is perfluoroether rubber; the insulation layer and the bottom inner wall of the packaging structure are provided with a first heat dissipation plate; the insulation layer and the two ...

Embodiment 3

[0045] A long-life lithium battery includes a packaging structure and a lithium battery cell arranged in the packaging structure. The lithium battery cell includes a first current collector, a negative electrode layer, an electrolyte layer, a positive electrode layer and a second current collector; the packaging structure includes the following Parts by weight of material:

[0046]

[0047] The number average molecular weight of polyethylene terephthalate is 20000g / mol; the thickness of the first current collector and the second current collector is 8μm; the thickness of the positive electrode layer is 60μm; the thickness of the electrolyte layer is 10μm; lithium battery cell There is also an insulating layer between the insulating layer and the packaging structure; the material of the insulating layer is tetrafluoroethylene-propylene copolymer; the insulating layer and the bottom inner wall of the packaging structure are provided with a first heat dissipation plate; There are a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com