Method for preparing bioelectrochemical system anode by using carbon nanotubes and carbon fibers

A technology of bioelectrochemistry and carbon nanotubes, which is applied in the field of bioelectrochemistry, can solve the problems of lower electron transfer efficiency due to internal resistance, inability to realize carbon fiber treatment, and insufficient number of microorganisms attached, so as to improve electron transfer efficiency and structural stability and conductivity, and the effect of improving the electrostatic adsorption function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

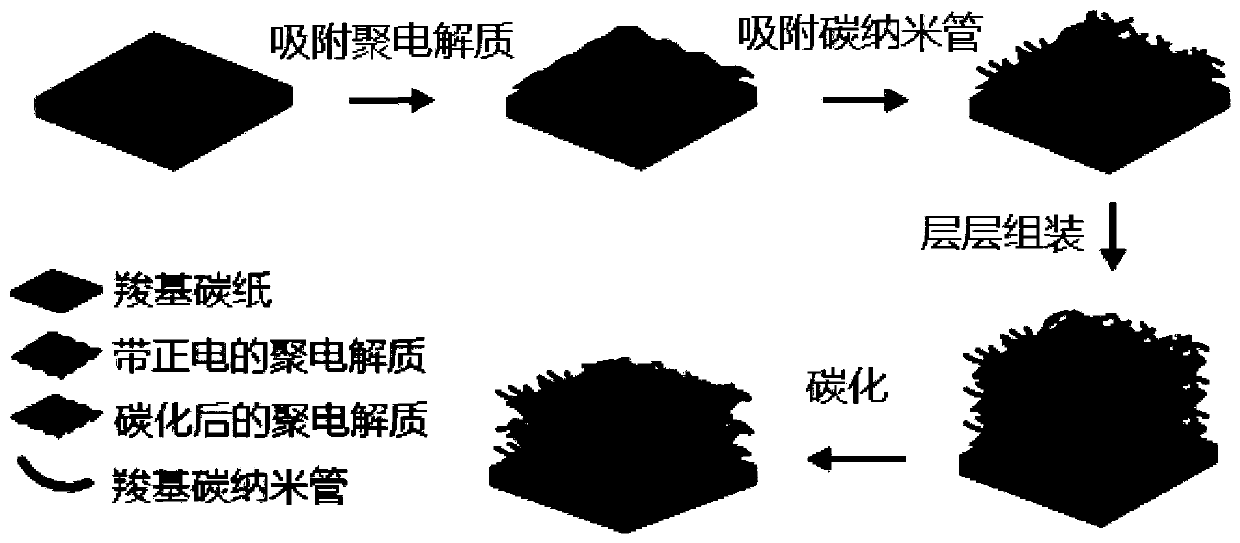

[0026] A method for preparing a bioelectrochemical system anode by using carbon nanotubes and carbon paper, the steps are as follows:

[0027] (1) Immerse 100mg carbon nanotubes and 85mg, 2×2cm carbon paper in a mixture of 20mL concentrated nitric acid and concentrated sulfuric acid (1:3, V / V) for 2 hours, dilute the carbon nanotube acid solution to 100mL, and sand The core funnel was vacuum-filtered several times until the filtrate was neutral, dispersed into 100mL of deionized water, and subjected to ultrasonication for 1min to obtain a carboxylated carbon nanotube dispersion. After the carbon paper was mixed with acid, it was washed until neutral to obtain carboxylated carbon paper;

[0028] (2) Immerse the carboxyl carbon paper in step (1) in a positively charged 10 mg / mL polyethyleneimine aqueous solution for 10 minutes, wash off the unabsorbed part with deionized water, and assemble the upper band on the carboxy carbon paper after drying. Positively charged polyethylenei...

Embodiment 2

[0033] A method for preparing a bioelectrochemical system anode by using carbon nanotubes and carbon felts, the steps are as follows:

[0034] (1) Immerse 3mg carbon nanotubes and 3mg, 2×2cm carbon felt in a mixture of 20mL concentrated nitric acid and concentrated sulfuric acid (1:5, V / V) for 4 hours, dilute the carbon nanotube acid solution to 100mL, and sand The core funnel was vacuum-filtered several times until the filtrate was neutral, dispersed into 100mL of deionized water, and ultrasonicated for 1min to obtain a carboxylated carbon nanotube dispersion, and the carbon felt was treated with mixed acid and washed until neutral to obtain a carboxylated carbon felt;

[0035] (2) Immerse the carboxyl carbon felt in step (1) in a positively charged 16 mg / mL polyethyleneimine aqueous solution for 15 minutes, wash away unabsorbed parts with deionized water, and assemble the upper band on the carboxyl carbon felt after drying. Positively charged polyethyleneimine;

[0036] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com