Molybdenum diselenide/nitrogen-doped carbon composite nano material, and preparation method and application thereof

A composite nanomaterial and nitrogen-doped carbon technology, which is applied in the field of molybdenum diselenide/nitrogen-doped carbon composite nanomaterials and the preparation thereof, can solve the problems of unstable structure, poor conductivity of molybdenum diselenide and the like, and achieves the preparation method. Simple, uniform morphology and size, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] S1. Dissolve 3 mmol of selenium powder in 10 mL of hydrazine hydrate to obtain a hydrazine hydrate solution of selenium.

[0059] S2. Dissolve 8.37 mmol of galactosamine in 50 mL of deionized water to form a solution, adjust the pH value of the solution to 5 with concentrated hydrochloric acid, add 1.5 mmol of sodium molybdate under stirring, and then add 10 mL of selenium hydrazine hydrate solution. After all dissolved, the molar ratio of galactosamine and sodium molybdate in the solution was 5.6:1, the molar ratio of selenium and sodium molybdate was 2:1, and the concentration of galactosamine was 0.14 mol / L.

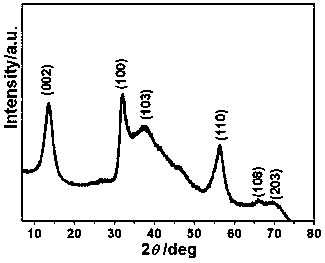

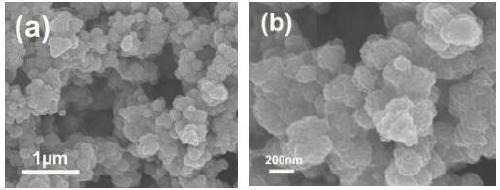

[0060] S3. Transfer the solution obtained in step S2. to a 100 mL stainless steel reactor lined with polytetrafluoroethylene. Placed in a dry box, hydrothermally reacted at 240°C for 24 hours. Then cool naturally to room temperature, rinse with deionized water and absolute ethanol three times respectively, centrifuge and vacuum dry at 60°C for 12 hours to obt...

Embodiment 2

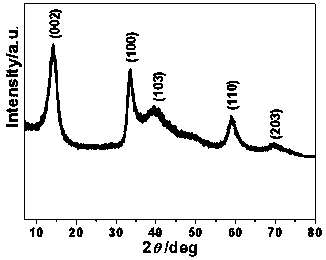

[0063] The difference between embodiment 2 and embodiment 1 is that the concentration of galactosamine in the solution of embodiment 2 is 0.28 mol / L;

[0064] Other conditions and operation steps are identical with embodiment 1.

Embodiment 3~7

[0066] The difference between Examples 3-7 and Example 1 is that the mol ratios of galactosamine and sodium molybdate in the solutions of Examples 3-7 are respectively 9.3:1, 3:1, 7:1, 10:1 and 15 : 1, the concentration of galactosamine is 0.23 mol / L;

[0067] Other conditions and operation steps are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inverse capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com