Preparation method of nickel oxide/three-dimensional structured graphene composite material

A composite material and graphene technology, applied in nanotechnology, structural parts, electrochemical generators, etc. for materials and surface science, can solve the problem of not fundamentally improving the performance of nickel oxide/three-dimensional structure graphene composite materials, Difficult to industrial application, low yield and other issues, to achieve good cycle stability, easy industrial mass production, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

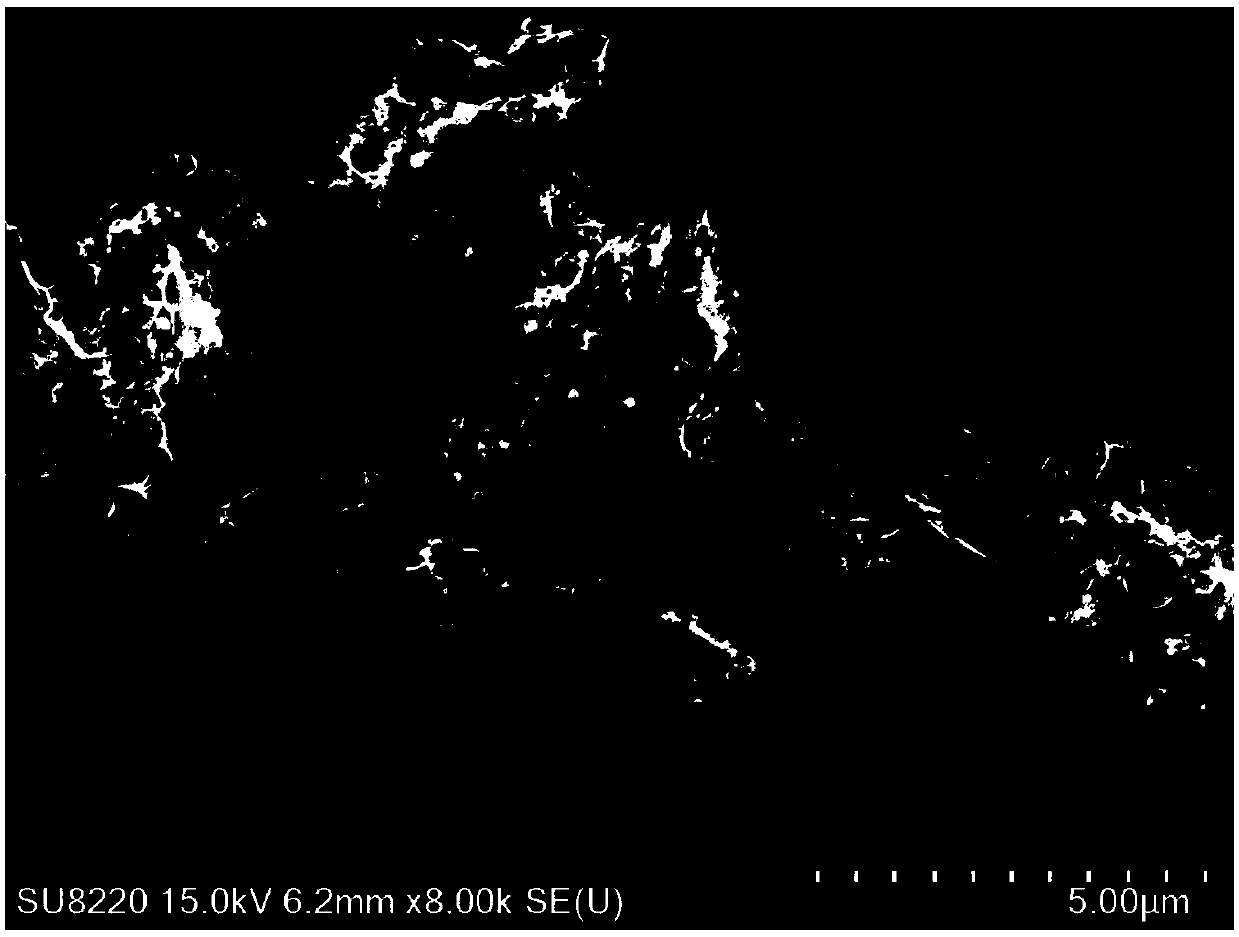

[0037] A preparation method of lithium ion battery nickel oxide / three-dimensional structure graphene negative electrode material, comprising the steps of:

[0038] (1) The PKS polymer is first pretreated, washed, and dried;

[0039] (2) The PKS polymer after pretreatment is joined in the nickel chloride solution of 2.0mol / L, suction filtration after mixing and stirring for 12h, removes filtrate;

[0040] (3) Add a certain amount of potassium hydroxide to the PKS polymer exchanged with nickel ions in the step (2) according to the mass ratio of 1:1, then add a certain amount of deionized water to make the potassium hydroxide just dissolve, stir and mix evenly, drying;

[0041] (4) heating the substance obtained in step (3) to 850° C. under a nitrogen atmosphere at a heating rate of 10° C. / min, and keeping the temperature constant for 2 hours;

[0042] (5) The obtained substance after heat treatment in the step (4) is washed several times with deionized water to remove impuriti...

Embodiment 2

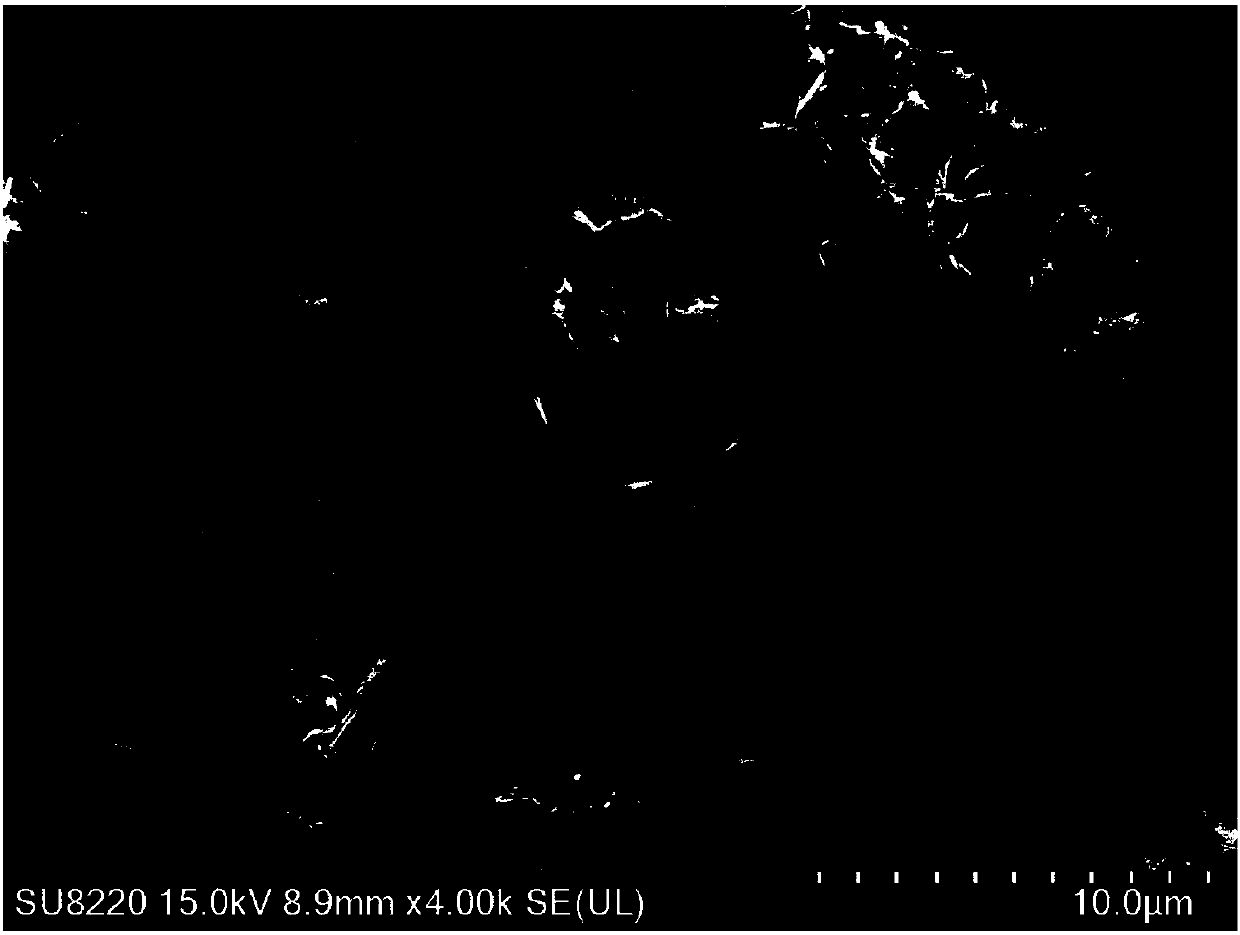

[0046] A preparation method of lithium ion battery nickel oxide / three-dimensional structure graphene negative electrode material, comprising the steps of:

[0047] (1) 0017 strongly acidic styrene-based cation exchange resin is first pretreated, washed, and dried;

[0048] (2) 0017 strongly acidic styrene series cation exchange resin after pretreatment is joined in the nickel sulfate solution of 1.0mol / L, suction filtration after mixing and stirring for 10h, removes filtrate;

[0049] (3) Add a certain amount of potassium hydroxide to the 0017 strongly acidic styrene-based cation exchange resin exchanged with nickel ions in step (2) at a mass ratio of 1:1, and then add a certain amount of deionized water to make the potassium hydroxide just Dissolve, stir and mix evenly, and dry;

[0050] (4) The substance obtained in step (3) is heated to 1000° C. under an argon atmosphere at a heating rate of 10° C. / min, and kept at a constant temperature for 4 hours;

[0051] (5) The obta...

Embodiment 3

[0055] A preparation method of lithium ion battery nickel oxide / three-dimensional structure graphene negative electrode material, comprising the steps of:

[0056] (1) D001 strong acid cation exchange resin is firstly pretreated, washed and dried;

[0057] (2) D001 strong acid cation exchange resin after pretreatment is joined in the nickel acetate solution of 1mol / L, suction filtration after mixing and stirring for 10h, removes filtrate;

[0058] (3) Add a certain amount of calcium hydroxide to the D001 strong acid cation exchange resin exchanged with nickel ions in step (2) according to the mass ratio of 1:1, then add a certain amount of deionized water to dissolve the calcium hydroxide, stir and mix uniform, dry;

[0059] (4) The substance obtained in step (3) is heated to 900° C. at a heating rate of 5° C. / min under a helium atmosphere, and kept at a constant temperature for 3 hours;

[0060] (5) The obtained material after heat treatment in step (4) is washed several ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com