DBR low refractive index layer etching method for reducing number of DBR cycles

A low-refractive-index layer and cycle number technology, applied to laser components, discharge tubes, electrical components, etc., can solve the problems of difficulty in obtaining uniform array holes, failure to obtain mature applications, and difficulty in obtaining array holes, etc., to achieve Reduce the evaporation protective layer, low cycle number, and control the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

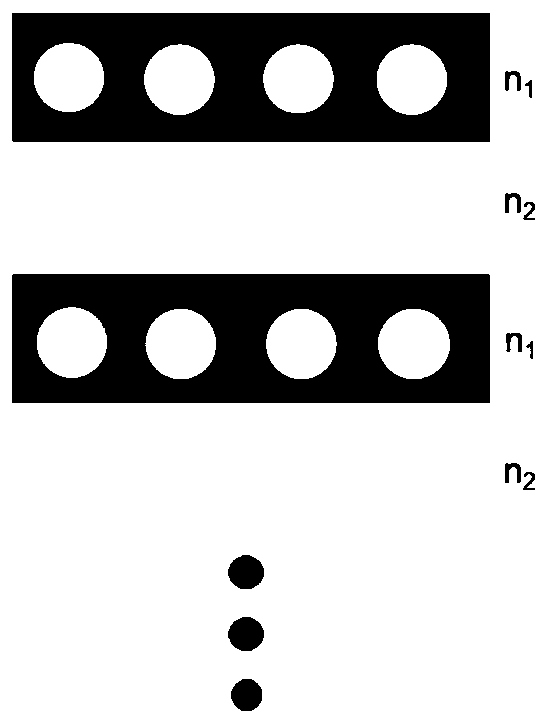

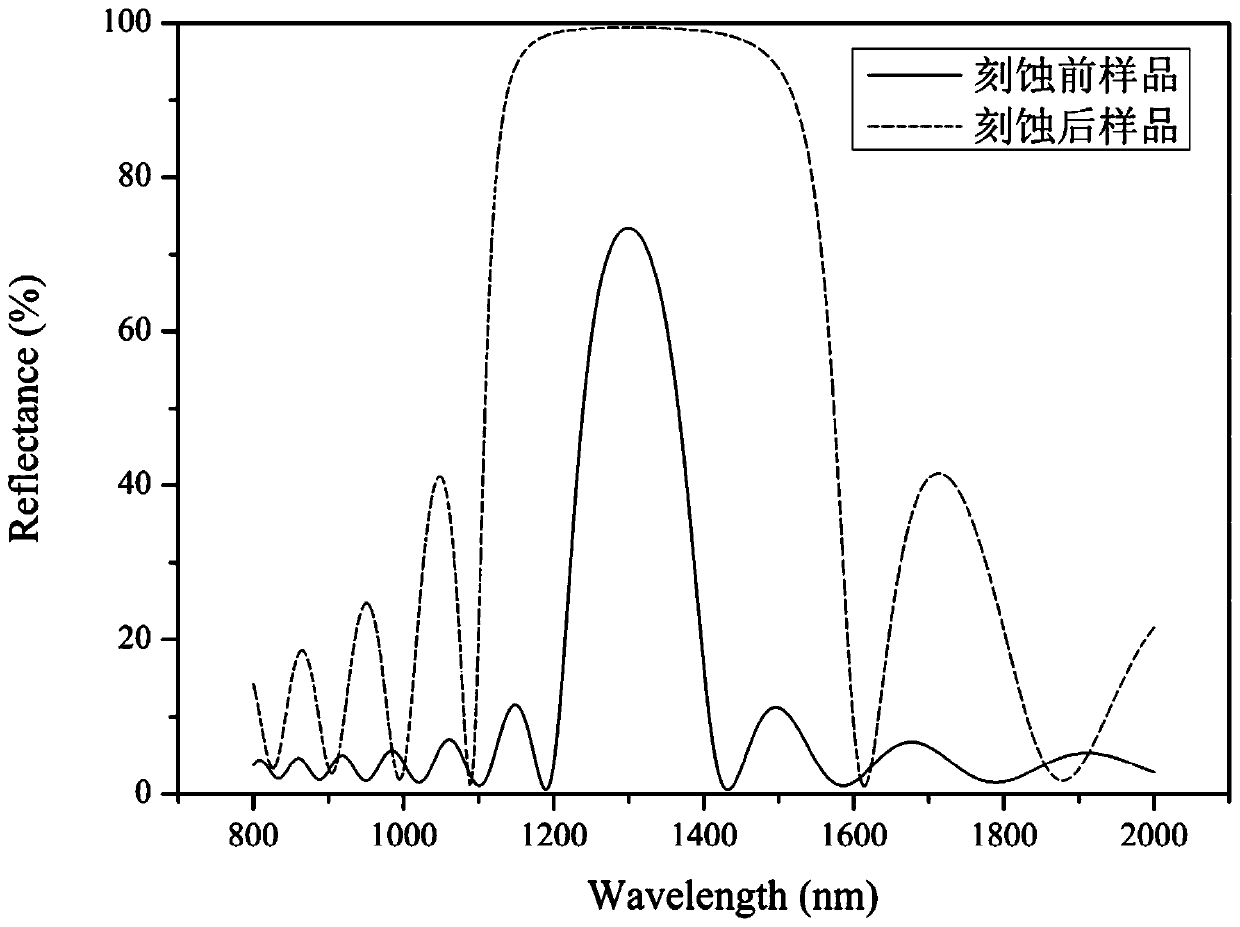

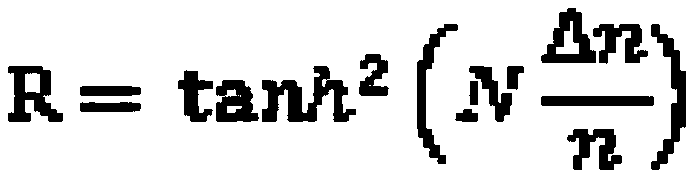

[0027] In VCSEL, DBR is the key to realize high-performance laser output, and it is also the difficulty of processing. In order to increase the refractive index difference between the two materials that make up the DBR and reduce the period number and series resistance of the DBR, the low refractive index film layer of the DBR is etched to prepare a mesoporous structure, thereby reducing the refractive index of the layer and improving the composition. The difference in refractive index between the two layers of the DBR achieves the purpose of reducing the period number of the DBR under the premise of satisfying the reflectivity. In the existing dry etching method, it is necessary to vapor-deposit a mask pattern before etch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com