Automatic edge finding method, system and equipment for laser cutting

An automatic edge finding and laser cutting technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of dangerous movement, scratching the surface of the plate, and affecting product quality, so as to achieve operational safety and improve work safety coefficient, the effect of highlighting substantive features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

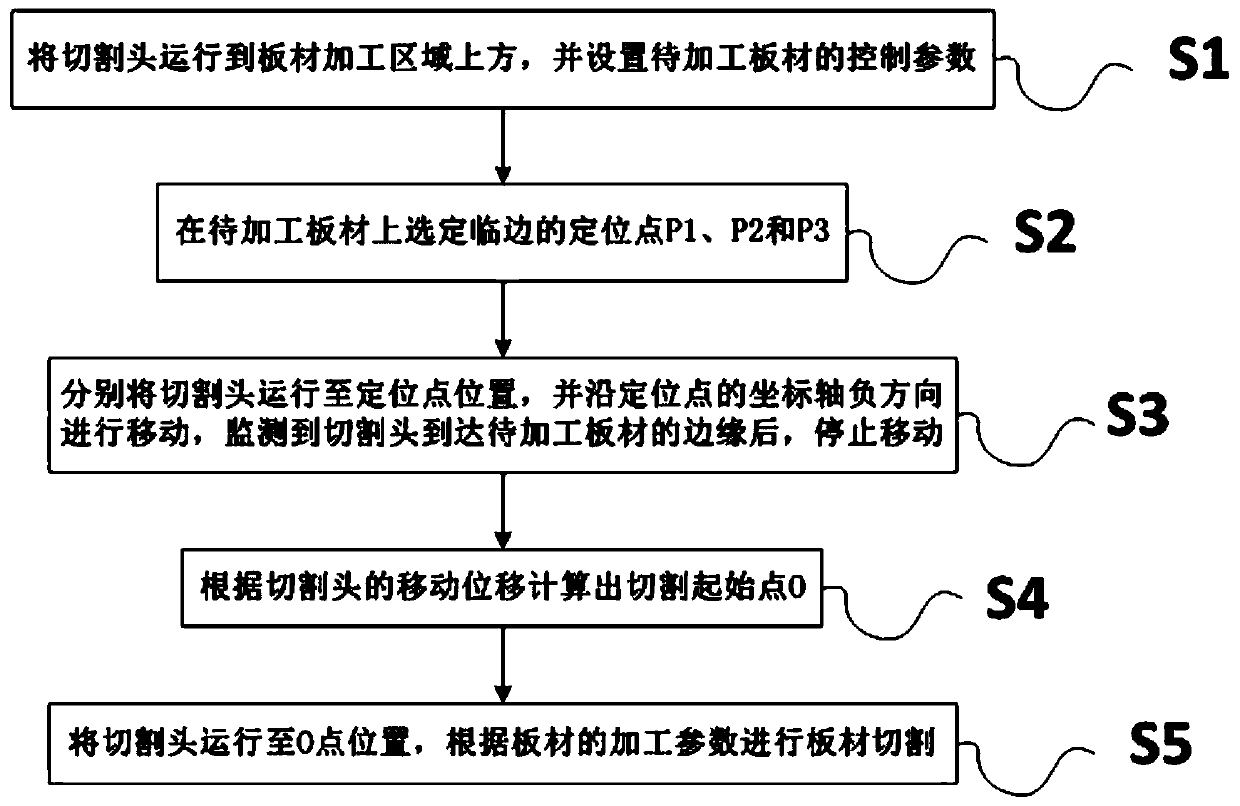

[0035] like figure 1 A laser cutting automatic edge finding method shown includes the following steps:

[0036] S1: Run the cutting head above the plate processing area, make the cutting head within the safety range of 30% to 70% of the plate size, and set the control parameters of the plate to be processed: such as edge-seeking height, edge-seeking speed, edge-seeking range Wait.

[0037] S2: Select the adjacent positioning points P1, P2 and P3 on the plate to be processed. It is required to locate the above three points within the safety range of 30% to 70% of the plate size. The system logic records the relevant positioning logic based on this safety factor.

[0038] S3: Run the cutting head directly to the position of the positioning point P1, record it as a mark point, click the automatic edge-seeking function to start automatic operation, and the system moves along the positioning points P1, P2, and P3 respectively according to the preset logical relationship and relate...

Embodiment 2

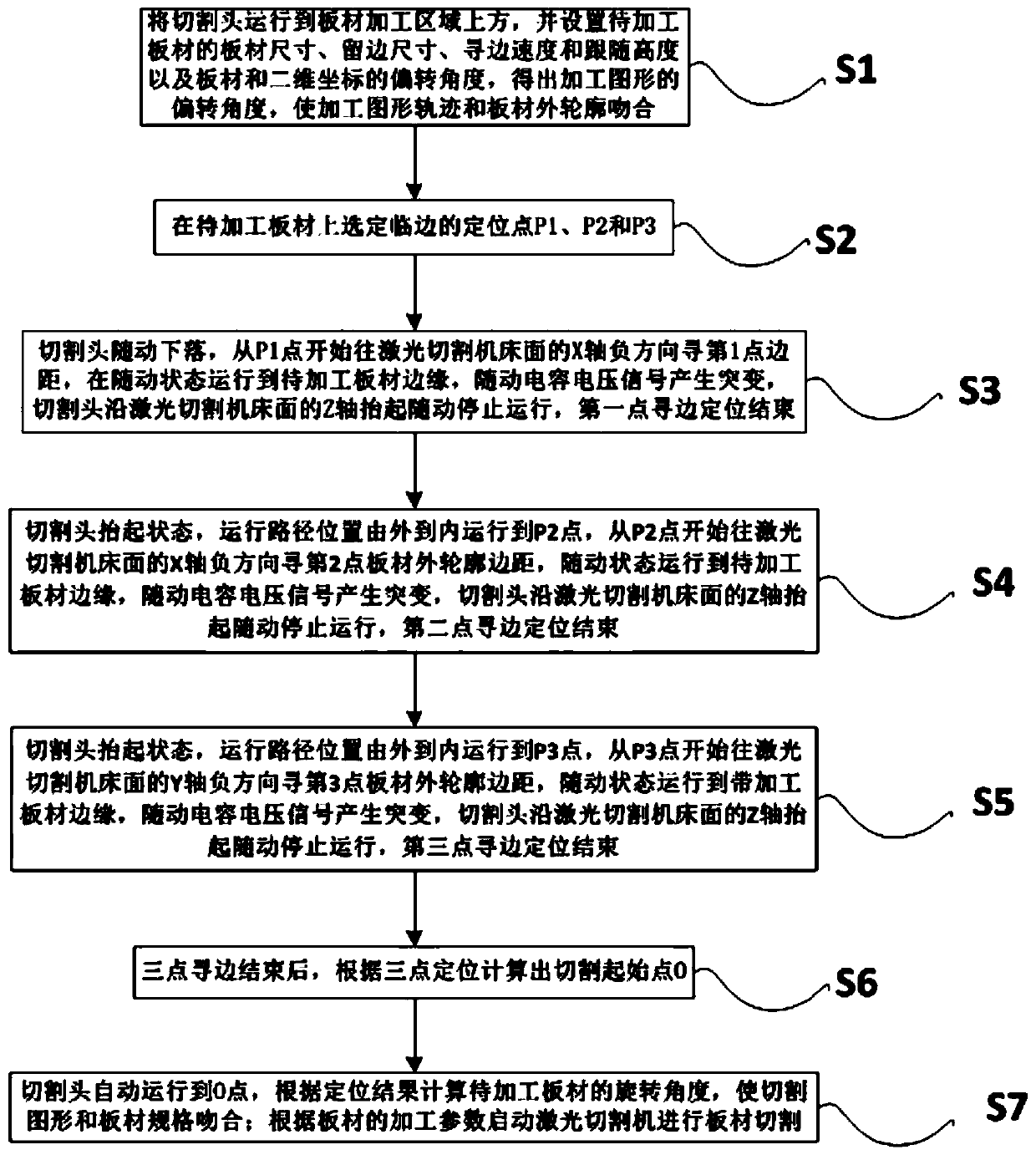

[0042] like figure 2 A laser cutting automatic edge finding method shown includes the following steps:

[0043] S1: Run the cutting head above the plate processing area, and set the plate size, edge size, edge-seeking speed and following height of the plate to be processed.

[0044] S2: Select the positioning points P1, P2 and P3 of the border on the plate to be processed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com