Deep silicon etching method for MEMS

A technology of deep silicon etching and etching cavity, which is applied in the process of producing decorative surface effects, decorative art, gaseous chemical plating, etc., can solve the problem of high roughness of side walls of MEMS devices, uneven etching, cavity The problem of high temperature of the chamber and sample stage can be solved to reduce surface contamination and damage, improve performance and reliability, and provide uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

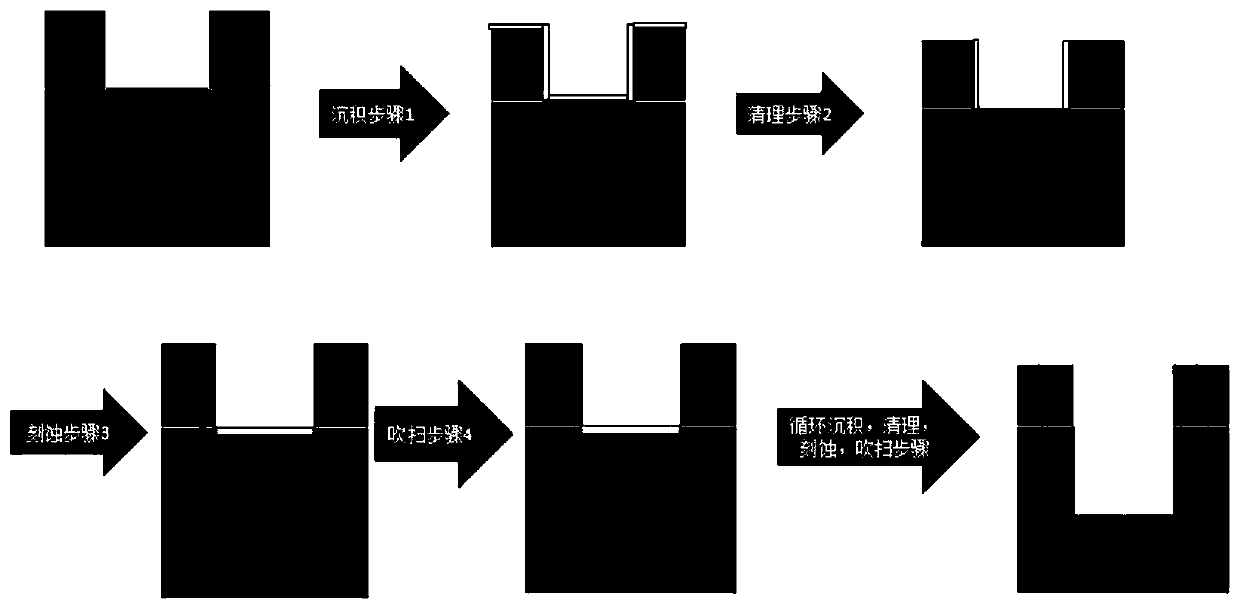

[0046] see Figure 1 to Figure 3 , the present invention is: a MEMS deep silicon etching method specifically includes the following content:

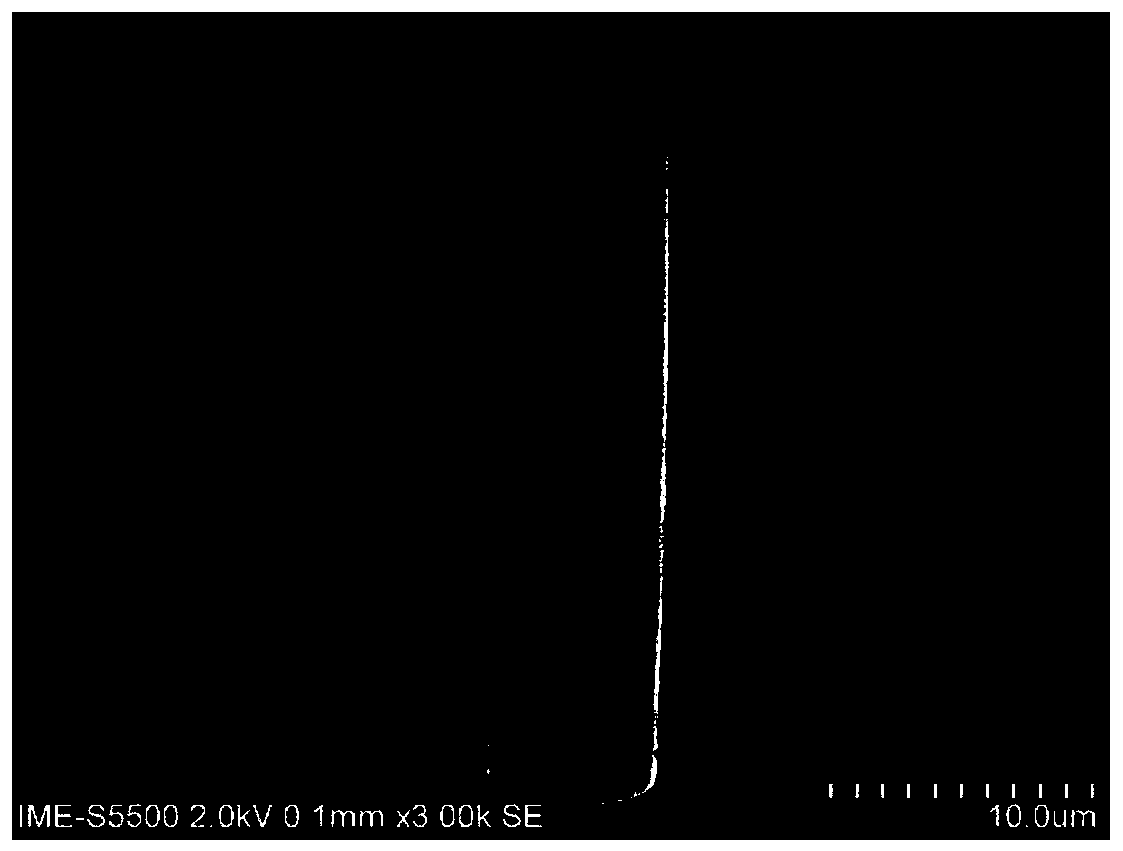

[0047] (1) Pretreatment steps of MEMS samples: the wafer is transferred from the transfer chamber to the vacuum reaction chamber, and a cycle of deposition steps, cleaning steps and etching steps are completed in the vacuum reaction chamber. After completing several cycles , the depth of silicon etching meets the requirements of MSMS devices, the MEMS devices are transferred from the vacuum reaction chamber to the transfer chamber, the wafer is returned to the atmosphere state, and the processing on the subsequent equipment is carried out; after the MEMS samples are subjected to the photolithography process, the The CD width of the photoresist is 50um, the line spacing is 40um, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com