A device for concentrating and crystallizing high-temperature salty wastewater and its application

A concentrating device and salty wastewater technology, which is applied in water/sewage treatment, water treatment parameter control, water/sewage multi-stage treatment, etc., can solve the problems of low automation degree of screen filtration, increased investment cost, and large manpower consumption. , to achieve the effect of reducing energy consumption, reducing manpower input, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

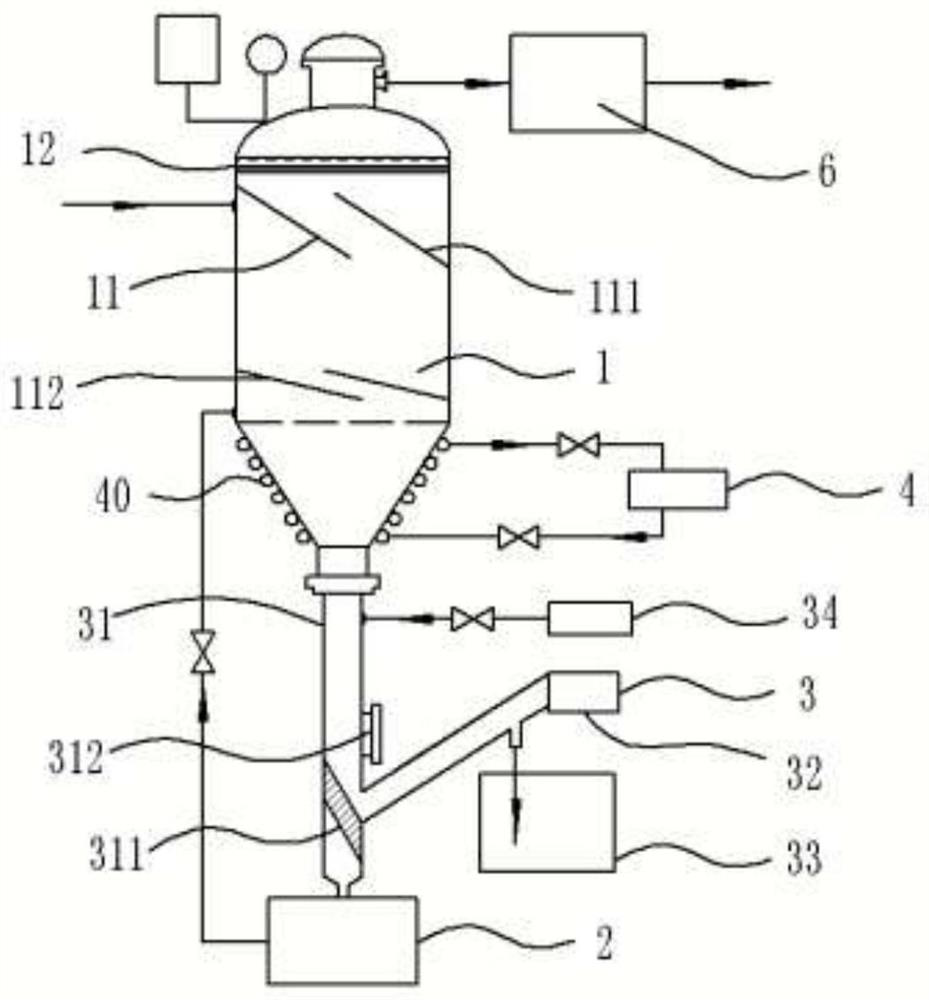

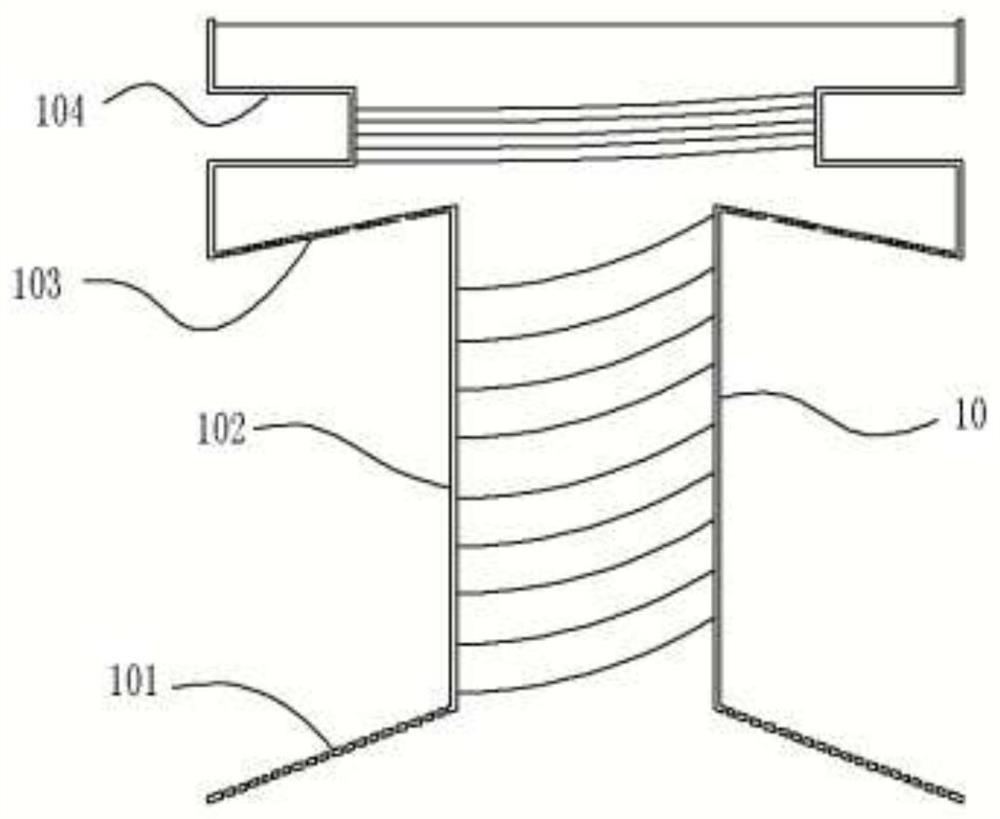

[0026] Embodiment 1: as figure 1 , 2 The shown high-temperature saline wastewater concentration and crystallization device includes a first concentration device 1 for the first concentration and crystallization, a second concentration device 2 for the second concentration, and a discharge device 3 for discharging , and a cooling device 4 for providing cooling for the first concentration device 1; the first concentration device 1 uses a flash tank, and the side wall of the first concentration device 1 is sequentially provided with a first feed port from top to bottom and the second feed port; the first feed port introduces the high-temperature saline waste water into the first concentration device 1 through the first decompression pump; the second feed port discharges the high temperature from the second concentration device 2 through the second decompression pump The concentrated brine is introduced into the first concentrator 1; the first concentrator 1 is provided with a de...

Embodiment 2

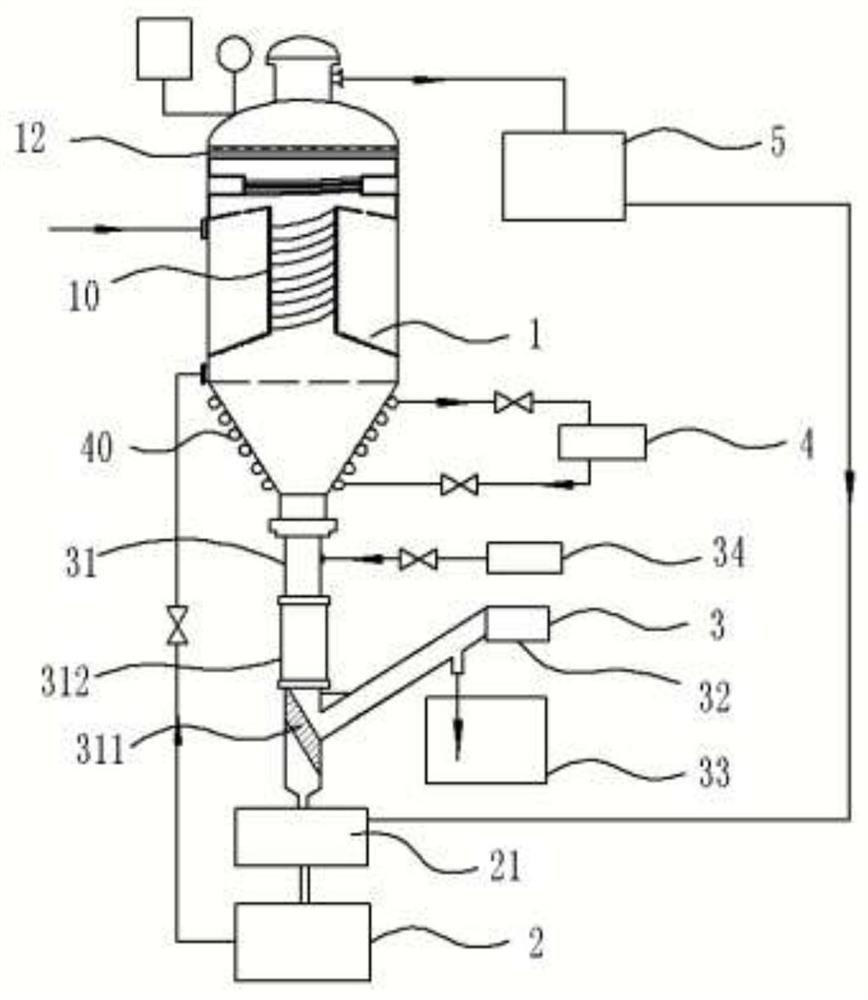

[0033] Embodiment 2: Different from Embodiment 1: as figure 2 As shown, a high-temperature salty wastewater concentration and crystallization device also includes a first compression device 5, and the first compression device 5 is used to recycle the vaporized steam inside the first concentration device 1 to heat energy; the first compression device 5 is specifically Roots blower is adopted; the second concentrating device 2 adopts a low-temperature salt steaming device, and a low-temperature steaming salt pretreatment device 21 is arranged at the connection between the feed port of the second concentrating device 2 and the lower end of the discharge pipeline 31; the low-temperature steaming salt pretreatment The device 21 includes a casing 211, a U-shaped flow pipe 212 and a steam heating pipe 213. The U-shaped flow pipe 212 is arranged inside the casing 211, and the steam heating pipe 213 is wound and arranged on the U-shaped flow pipe 212; the U-shaped flow pipe 212 The wa...

Embodiment 3

[0037] Example 3: The difference from Example 1 is that the heat and water required for the pretreatment process of high-salt and high-COD chemical hazardous waste by the hydrothermolysis method are provided by the first concentration device; The treatment process requires heat and water, so the vaporized steam inside the first concentration device is directly passed to the pretreatment system, which can make full use of heat and water and save energy.

[0038] When in use, the high-temperature saline wastewater produced by hydrothermal treatment of high-salt, high-COD chemical hazardous waste enters the first concentration device 1 through the first feed port, and then the water is quickly separated, and the separated steam is directly passed through the hydrothermal method. In the pretreatment system for treating high-salt and high-COD chemical hazardous waste; in addition, the concentrated wastewater is cooled at the bottom of the first concentration device 1. According to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com