High-temperature liquid metal detecting system

A liquid metal and detection system technology, applied in thermometers, measuring devices, measuring heat, etc., can solve the problems of inability to realize liquid metal detection, easy interference, difficult operation, etc., to avoid single-point failure and improve equipment space utilization. , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

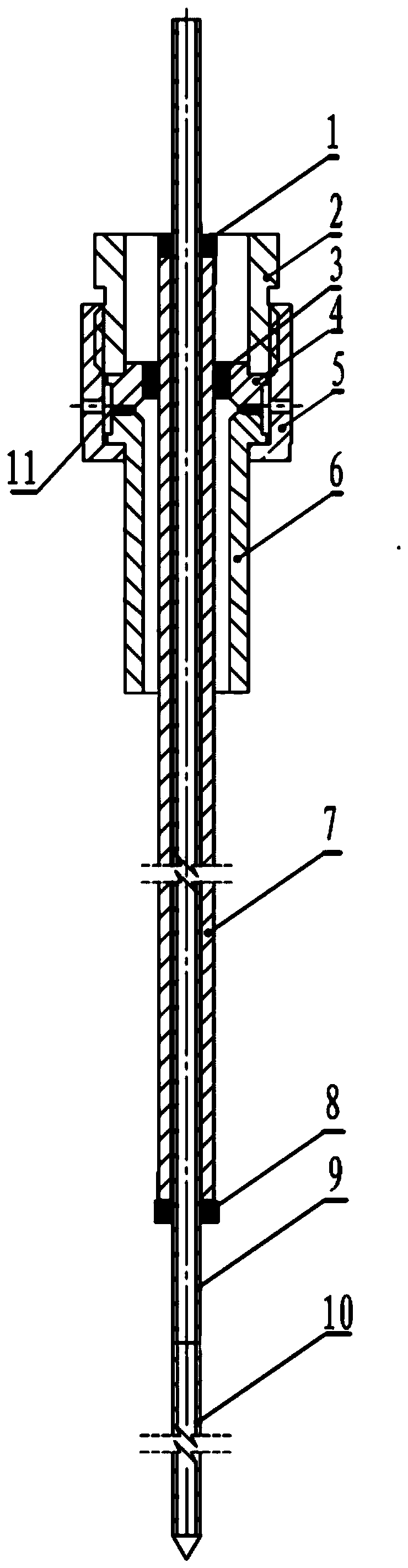

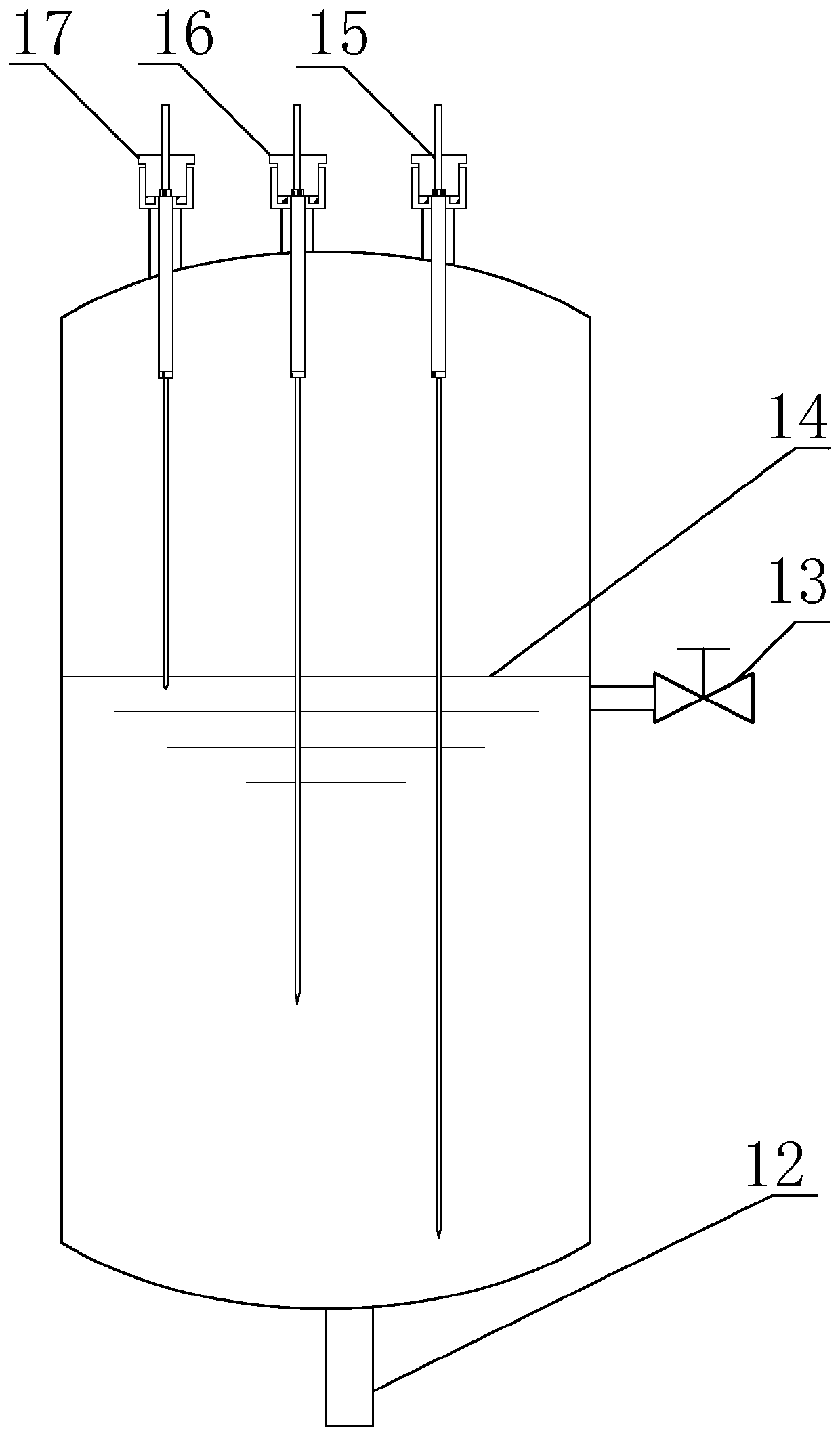

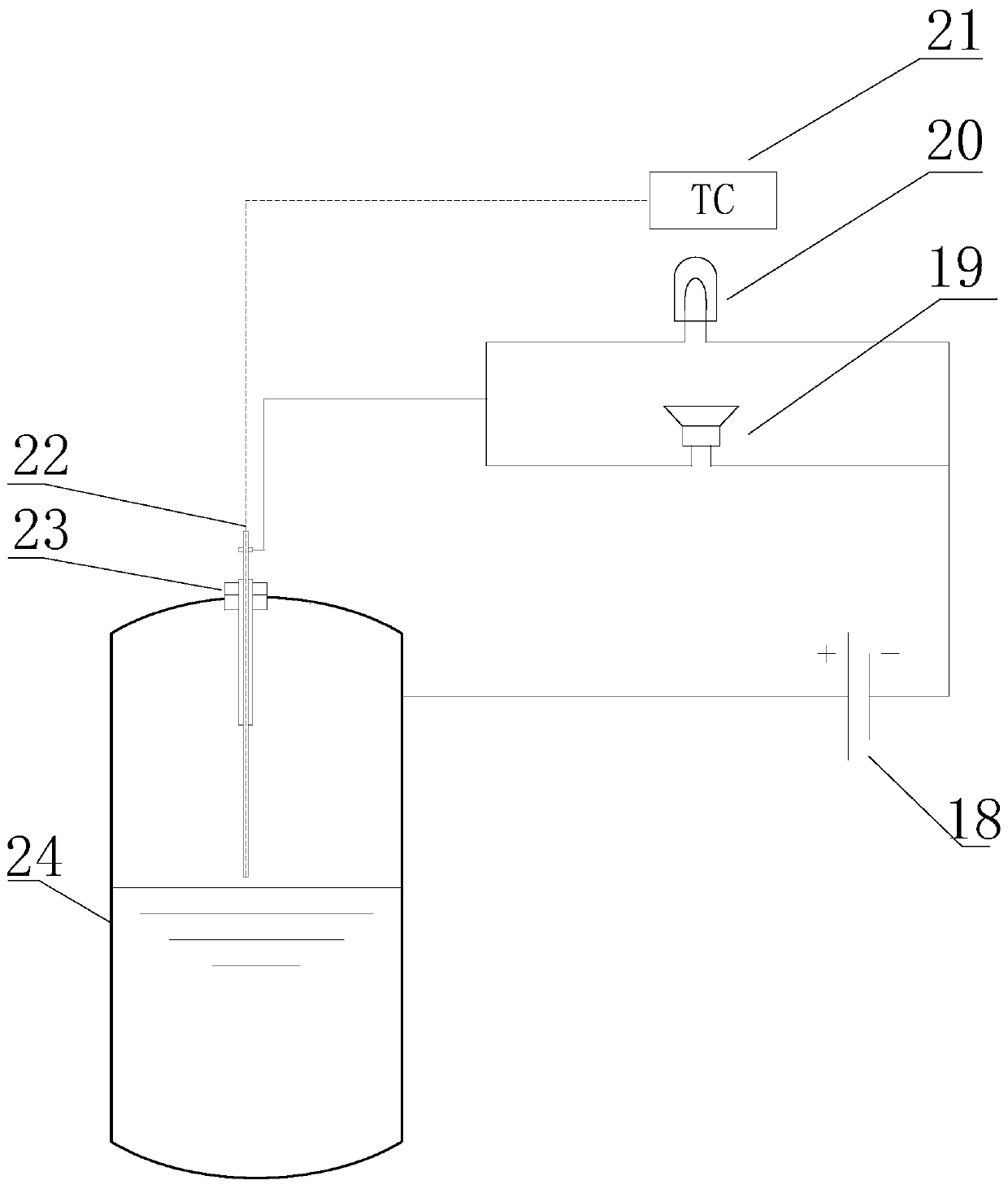

[0041] In order to more clearly illustrate the technical solution of the high-temperature liquid metal detection system of the present disclosure, the following combination figure 1 , figure 2 and image 3 And the specific embodiment describes in detail the technical solution provided by the present disclosure:

[0042] A high-temperature liquid metal detection system, the system includes: a power supply 18, a warning device, a thermocouple temperature display 21, an armored thermocouple wire 22, a high-temperature liquid metal probe 23; wherein the high-temperature liquid metal probe 23, a power supply 18, a warning The devices are connected in series through conduction; wherein the high-temperature liquid metal probe 23 includes: a transition piece, an insulating piece, a sealing piece, and a structural piece for supporting and fixing; wherein the sealing piece and the insulating piece are connected by a transition piece; wherein the insulating piece High temperature resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com