Fabrication of NiCo2O4/graphene aerogel/foamed nickel composite electrode and application of high-performance supercapacitor

A graphene hydrogel and composite electrode technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor collectors, etc., can solve the problems of time-consuming, unutilized gap space of nickel foam, and complicated preparation process, etc. problem, to achieve the effect of fast electron and ion transport, good electrochemical capacitive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

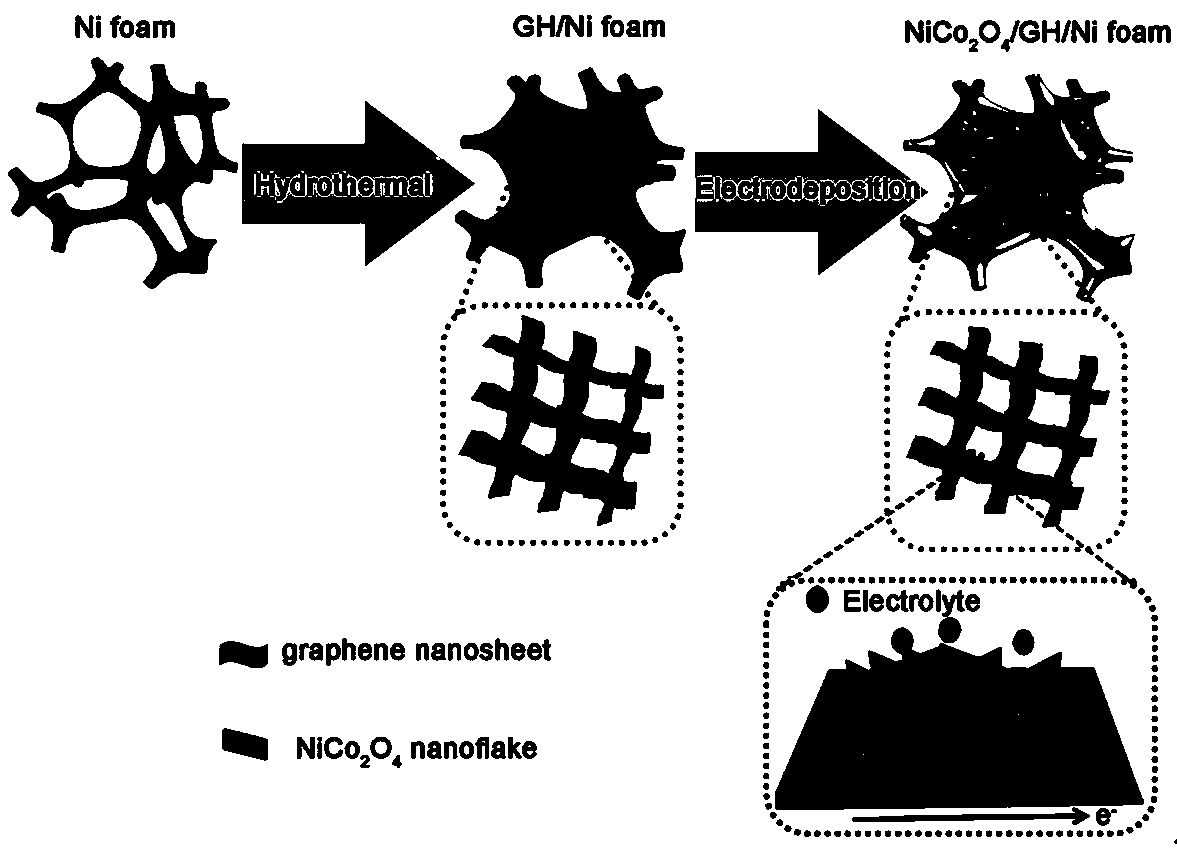

[0034] A kind of NiCo 2 O 4 / Graphene hydrogel / foam nickel composite electrode preparation method, such as figure 1 As shown, including the following steps:

[0035] 1) Preparation of conductive substrate: 5mL of graphene oxide solution with a concentration of 2mg / ml was transferred to a 10mL hydrothermal reactor, foamed nickel was immersed in it, the reactor was sealed, and kept at 180°C for 12h to obtain graphene hydrogel / Foam nickel (GF) composite material, washed with deionized water to obtain graphene hydrogel / foam nickel substrate;

[0036] Among them, graphene oxide is prepared by the Hummers method [for specific preparation, please refer to WS Hummers, REOffeman, Preparation of Graphitic Oxide, J. Am. Chem. Soc. 80 (1958) 1339-1342. and S. Gao, L. Zhang, Y.Qiao,P.Dong,S.Cao,Electrodeposition of polyaniline on three-dimensional graphene hydrogel as a binder-free supercapacitor electrode with high power and energy densities,RSC Adv.6(2016)58854-58861], foam nickel (10mm ×10...

Embodiment 2

[0039] NiCo described in this embodiment 2 O 4 The preparation method of / graphene hydrogel / foamed nickel composite electrode is different from Example 1 in that the concentration of the graphene oxide aqueous solution is 1.5 mg / mL, the reactor is sealed, and the graphene hydrogel is obtained by keeping it at 220°C for 6 hours. Glue / foam nickel (GF) composite material. The rest are the same as in Example 1.

Embodiment 3

[0041] NiCo described in this embodiment 2 O 4 The preparation method of / graphene hydrogel / foamed nickel composite electrode is different from Example 1 in that the concentration of the graphene oxide aqueous solution is 5.0 mg / mL, the reactor is sealed, and the graphene hydrogel is obtained by keeping it at 120°C for 12 hours. Glue / foam nickel (GF) composite material. The rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com