a kind of nico 2 o 4 /Preparation of graphene hydrogel/nickel foam composite electrode and its application in high-performance supercapacitors

A graphene hydrogel, composite electrode technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor current collectors, etc., can solve the problem of unutilized nickel foam gap space, time-consuming, small substrate surface area, etc. problem, to achieve the effect of good electrochemical capacitance performance, fast electron and ion transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

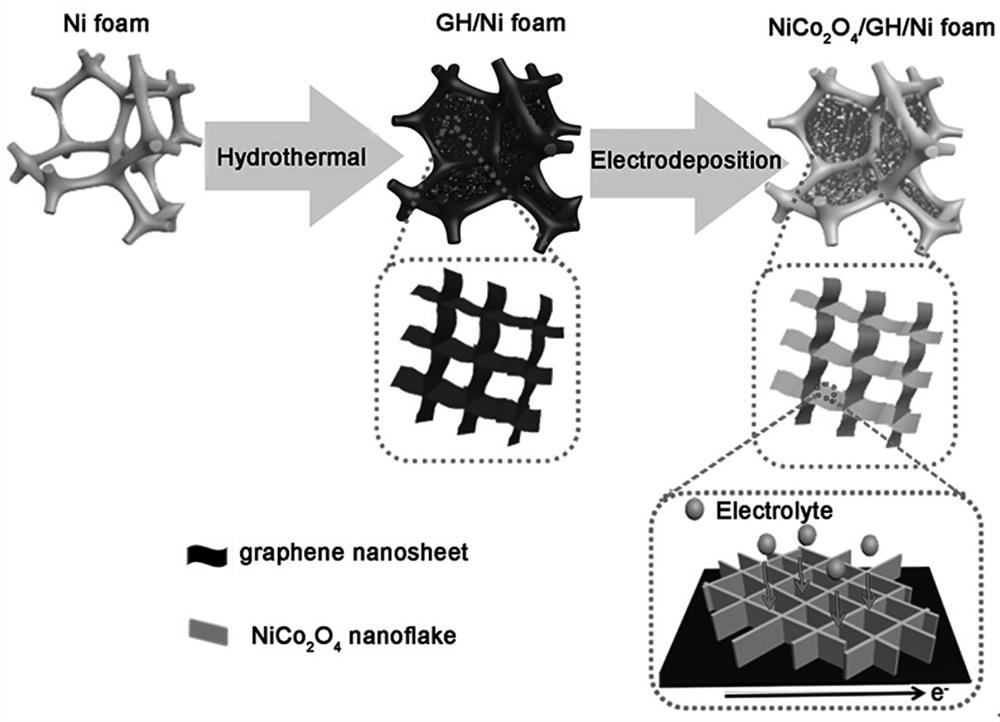

[0034] A kind of NiCo 2 o 4 The preparation method of / graphene hydrogel / nickel foam composite electrode, as figure 1 shown, including the following steps:

[0035] 1) Preparation of conductive substrate: transfer 5mL of graphene oxide solution with a concentration of 2mg / ml into a 10mL hydrothermal reactor, soak nickel foam in it, seal the reactor, and keep it at 180°C for 12h to obtain a graphene hydrogel / foam nickel (GF) composite material, obtain graphene hydrogel / foam nickel substrate after washing with deionized water;

[0036] Wherein, graphene oxide is prepared by the Hummers method [specific preparation can refer to W.S.Hummers, R.E.Offeman, Preparation of Graphitic Oxide, J.Am.Chem.Soc.80 (1958) 1339-1342. and S.Gao, L.Zhang, Y. Qiao, P.Dong, S.Cao, Electrodeposition of polyaniline onthree-dimensional graphene hydrogel as a binder-free supercapacitor electrode with high power and energy densities, RSC Adv.6(2016) 58854-58861], nickel foam (10mm× 10mm×1mm) were wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com