Composite stent and preparation method thereof

A technology of composite scaffolds and alternating repetition, applied in medical science, tissue regeneration, prostheses, etc., can solve the problems affecting the forming quality of composite scaffolds, unable to use large-scale production, difficult to mix uniformly, etc., to promote cell adhesion and value-added , shorten the mineralization time, improve the effect of deposition uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] A composite support is composed of silk fibroin three-dimensional microporous support and hydroxyapatite, and the hydroxyapatite is evenly deposited on the surface of the silk fibroin support.

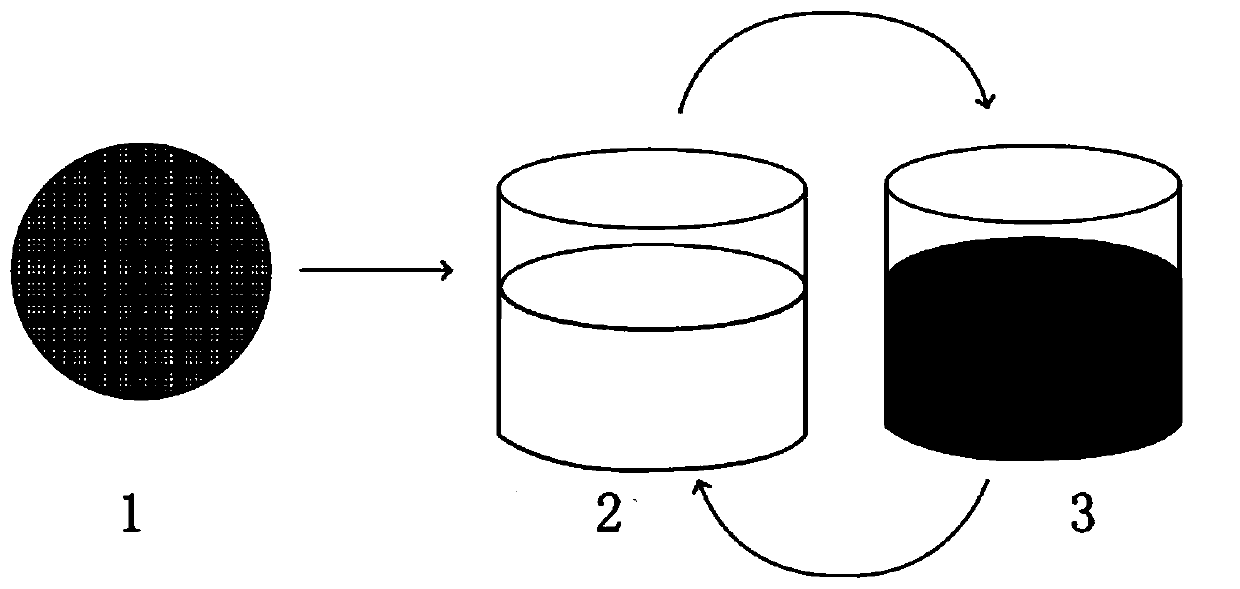

[0045] see figure 1 , the preparation method is as follows:

[0046] ⑴. Preparation of silk fibroin three-dimensional microporous scaffold 1

[0047] ①. Put the raw silk in 0.5% (w / v) Na 2 CO 3 Boil in the solution for 45 minutes, then thoroughly wash with distilled water to remove sericin, and dissolve silk fibroin in 9.3mol / L LiBr solution after drying, and dissolve at 60°C for 1 hour. Obtain 6% (w / v) silk fibroin solution after filtration, dialysis and centrifugation;

[0048] ②. Slowly concentrate the silk fibroin solution in an oven at 60°C for 24 hours to obtain a 20% (w / v) silk fibroin concentrate;

[0049] ③. Dilute the concentrated solution to 0.5% (w / v) with ultrapure water, and then incubate at 60°C for 24 hours to induce the formation of nanofibers to obtain a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com