Full-body porous polycaprolactone fiber and preparation method thereof

A polycaprolactone and fiber technology, applied in fiber processing, textile and papermaking, filament/thread forming, etc., can solve the problems of spinning solution polarity, affecting fiber structure and performance, affecting fiber purity, etc. Achieve good biocompatibility and mechanical properties, ultra-high specific surface area and porosity, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of whole body porous polycaprolactone fiber, its preparation method comprises the steps:

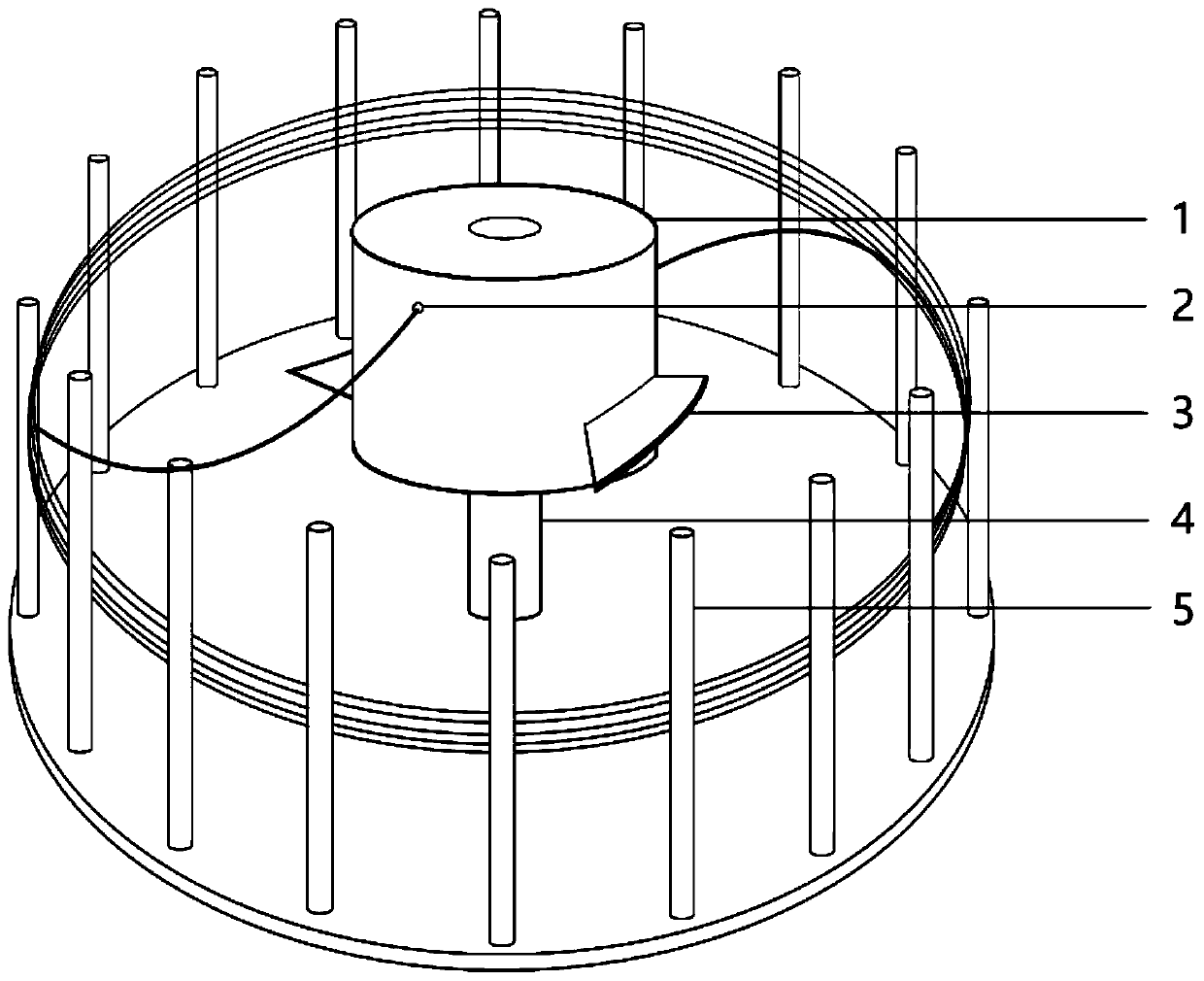

[0040] (1) Build a centrifugal spinning device: install 3 fan blades under the spinneret hole of the traditional solution centrifugal spinning device;

[0041] (2) Preparation of spinning solution: 1.5g of polycaprolactone was added to 10mL of dichloromethane, and stirred evenly at room temperature to make a polycaprolactone spinning solution with a concentration of 0.15g / mL;

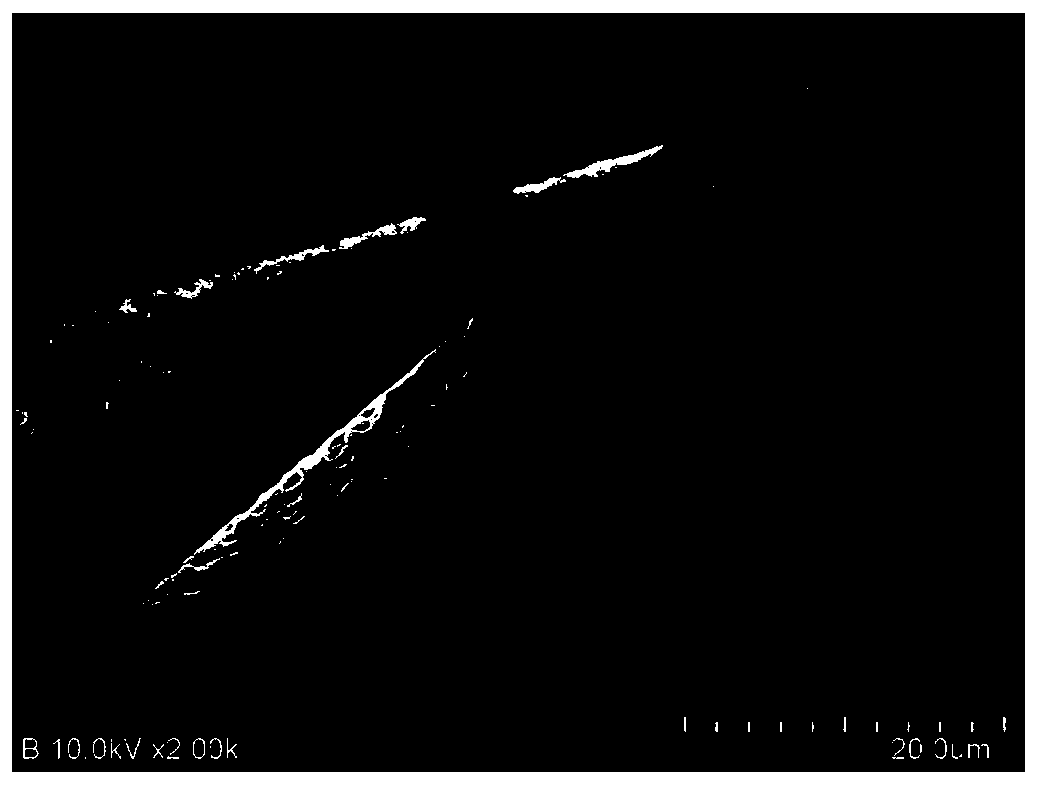

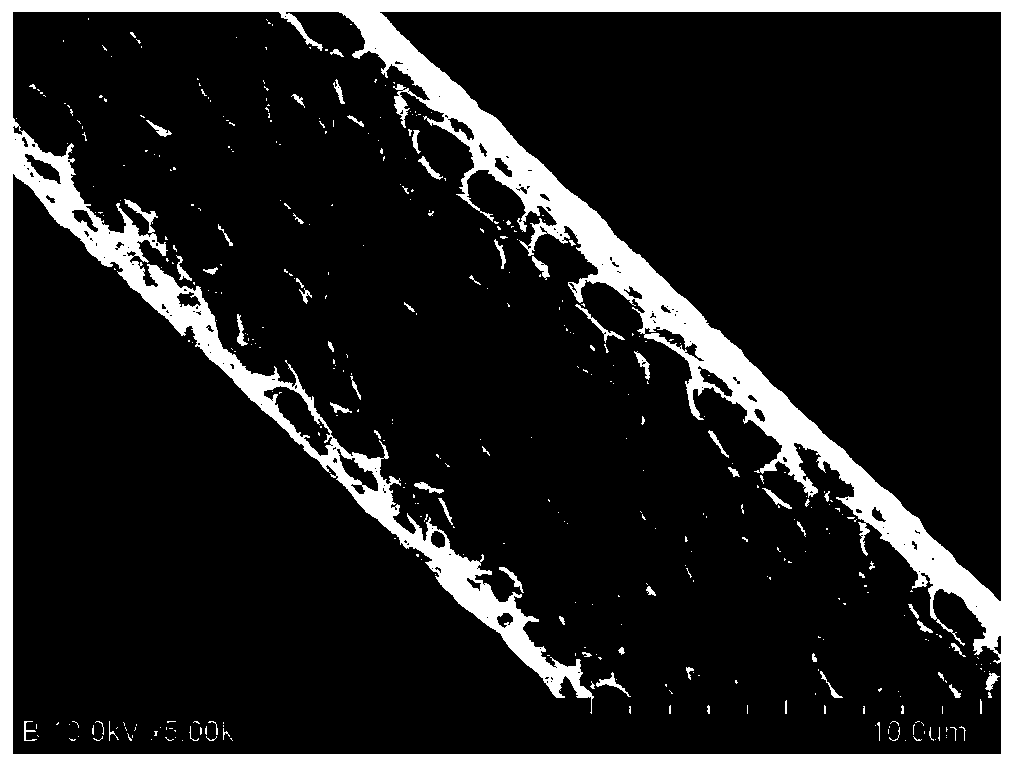

[0042] (3) Carry out centrifugal spinning: (2) gained solution is injected in the spinneret, under the parameter that 1500rpm / min, receiving distance are carried out centrifugal spinning under the parameter of 8cm by (2) gained solution, obtain polycaprolactone porous fiber (such as figure 2 , 3 shown).

Embodiment 2

[0044] A kind of whole body porous polycaprolactone fiber, its preparation method comprises the steps:

[0045] (1) Build a centrifugal spinning device: install 3 fan blades under the spinneret hole of the traditional solution centrifugal spinning device;

[0046] (2) Preparation of spinning solution: 1.7g of polycaprolactone was added to 10mL of dichloromethane, and stirred evenly at room temperature to make a polycaprolactone spinning solution with a concentration of 0.17g / mL;

[0047] (3) Carry out centrifugal spinning: (2) gained solution is injected in the spinneret, is that 2000rpm / min, receiving distance are carried out centrifugal spinning under the parameter of 10cm at the number of revolutions, obtains polycaprolactone porous fiber (such as Figure 4 , 5 shown).

Embodiment 3

[0049] A kind of whole body porous polycaprolactone fiber, its preparation method comprises the steps:

[0050] (1) Build a centrifugal spinning device: install 3 fan blades under the spinneret hole of the traditional solution centrifugal spinning device;

[0051] (2) Preparation of spinning solution: 1.9g of polycaprolactone was added to 10mL of dichloromethane, and stirred evenly at room temperature to make a polycaprolactone spinning solution with a concentration of 0.19g / mL;

[0052] (3) Carry out centrifugal spinning: (2) gained solution is injected in the spinneret, is that 2500rpm / min, receiving distance are carried out centrifugal spinning under the parameter that is 12cm at the number of revolutions, obtains polycaprolactone porous fiber (such as Figure 6 , 7 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com