Method for preparing double-layer hollow spherical nickel cobaltate nanoparticles

A nanoparticle and hollow spherical technology is applied in the field of preparation of double-shell hollow spherical nickel cobaltate nanoparticles, which can solve the problems of single product morphology, cumbersome operation, environmental pollution, etc., and achieves high chemical activity, simple operation and low price. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

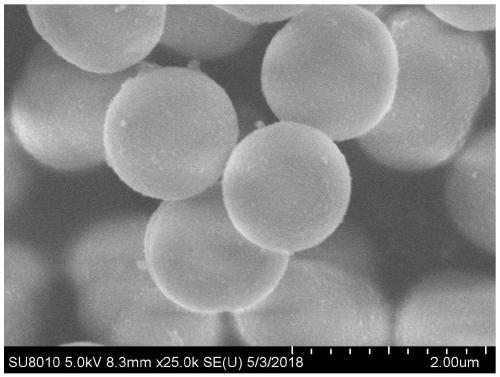

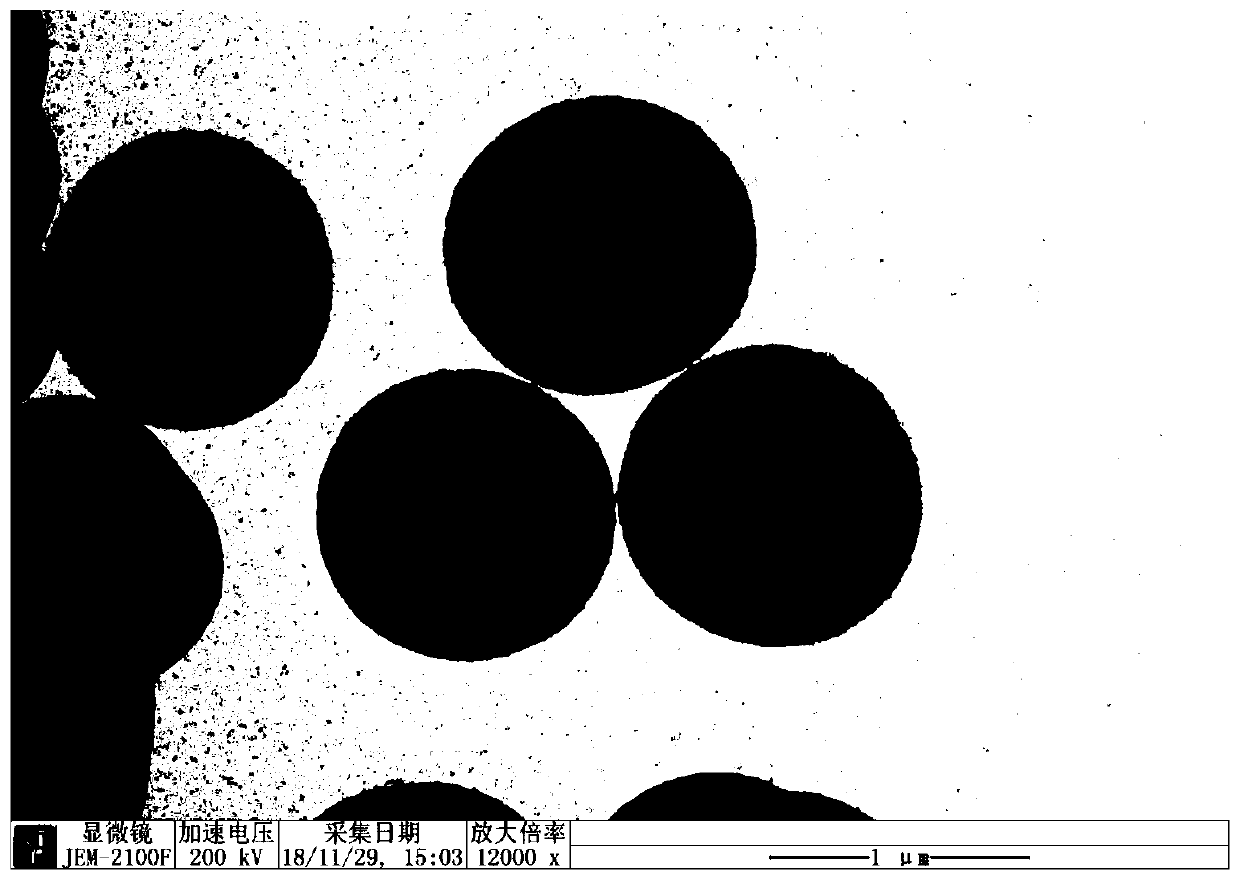

[0026] Stir and mix 1.5 mmol D-xylose powder with 30 ml isopropanol, then add 0.5 mmol Ni(NO 3 ) 2 ·6H 2 O and 1 mmol Co(NO 3 ) 2 ·6H 2 O was added to the above solution, stirred evenly, transferred to a 50 ml reaction kettle, sealed, placed in an oven at 180°C, and the reaction continued for 24 hours. After the reaction was completed, the solution was centrifuged and cleaned twice with water and ethanol, and then dried and collected to obtain a solid spherical carbonaceous microsphere precursor. The scanning photos and transmission photos are shown in the attached figure 1 And attached figure 2 .

Embodiment 2

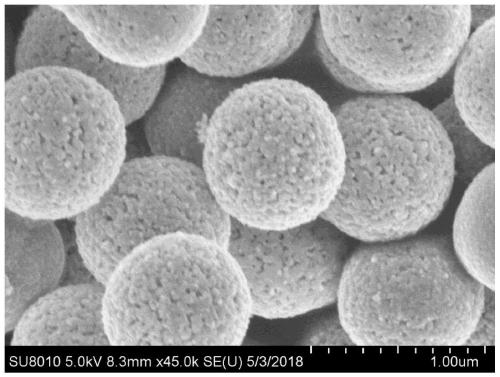

[0028] The sample prepared in Example 1 was annealed, the sample was put into a crucible and placed in a muffle furnace, and the temperature was raised to 450°C at a heating rate of 5°C / min, and kept for 2h to obtain a solid spherical NiCo 2 o 4 Nanospheres, its scanning photo and transmission photo are shown in the attached image 3 And attached Figure 4 .

Embodiment 3

[0030] As in Example 2, the sample prepared in Example 1 was annealed, but the heating rate was changed to 7°C / min, and other conditions remained unchanged, and a single-shell hollow spherical NiCo2 o 4 Nanospheres, its scanning photo and transmission photo are shown in the attached Figure 5 And attached Figure 6 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap