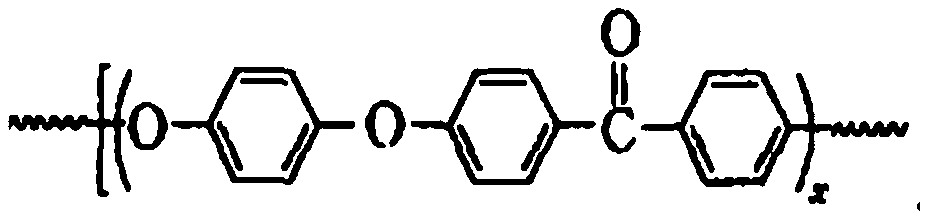

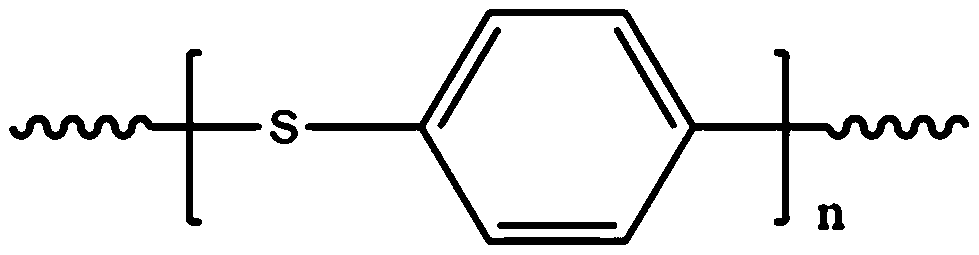

High thermal conduction polyether ether ketone resin and molding product thereof

A technology for polyetheretherketone resin and polyetheretherketone, which is applied in the field of high thermal conductivity polyetheretherketone resin and its molded products, can solve the problems of difficulty in producing polyetheretherketone resin and the reduction of mechanical properties such as impact strength. , to achieve the effect of balancing tensile strength and impact strength, improving thermal conductivity, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

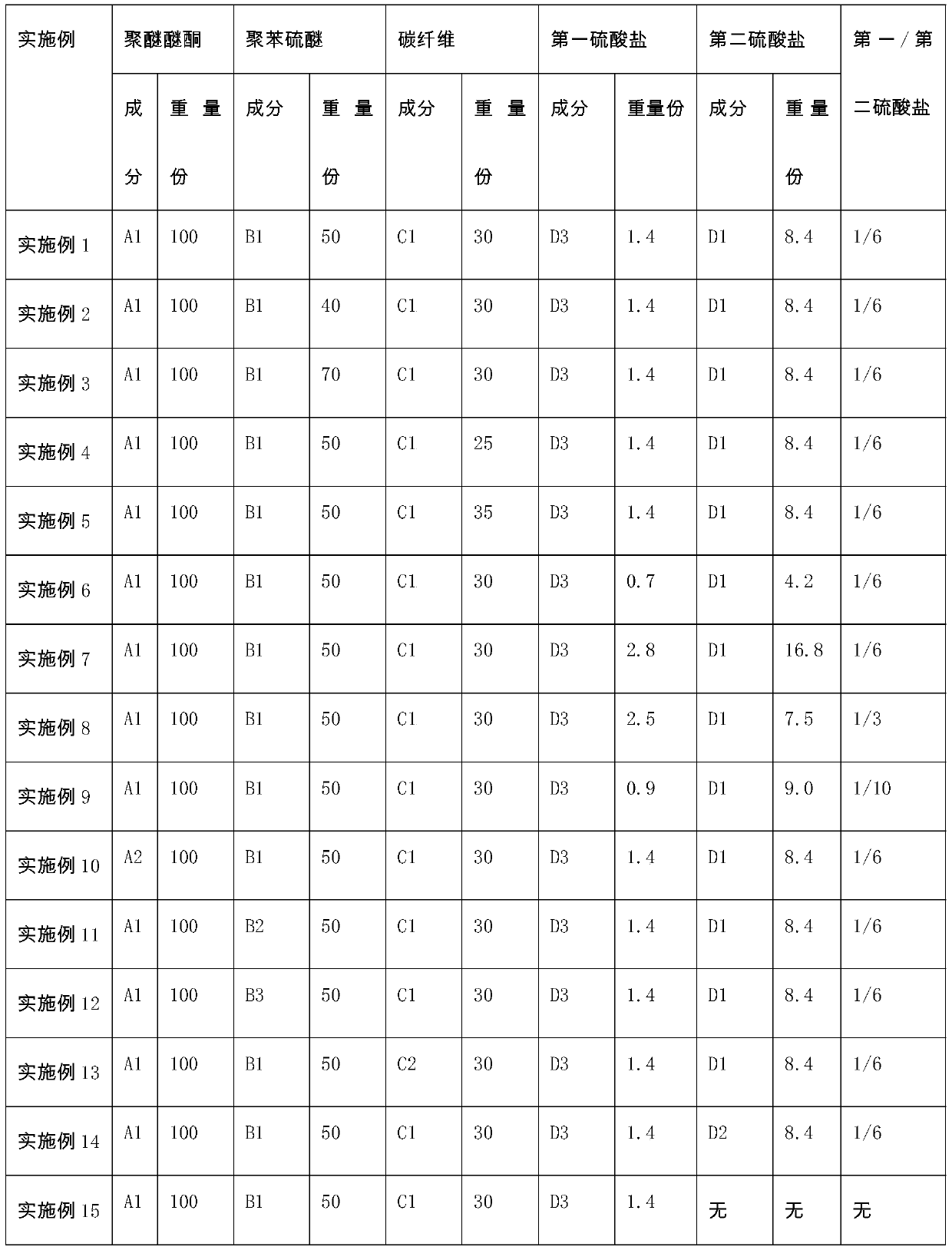

Embodiment 1~15

[0072] The high thermal conductivity polyether ether ketone material was prepared by the following method: blend polyphenylene sulfide, sulfate and 60% carbon fiber at 350°C according to the ingredients and proportions shown in Table 1, and keep the shear rate at 150~ 250s -1 , to obtain the first blend; then at 400°C, the first blend, polyetheretherketone and the remaining 40% of carbon fibers were blended according to the ingredients and proportions shown in Table 1, and the shear rate was kept at 80~140s -1 , to prepare polyether ether ketone material with high thermal conductivity. Then it was molded at 350°C into samples required for tensile and impact tests, and various performance tests were performed. The results are listed in Table 2.

Embodiment 16

[0074] Blend polyether ether ketone, polyphenylene sulfide, carbon fiber, magnesium sulfate and barium sulfate at 400°C according to the ingredients and proportions in Example 1, and keep the shear rate at 150-250s -1 . Then it was molded at 350°C into samples required for tensile and impact tests, and various performance tests were performed. The results are listed in Table 2.

Embodiment 17

[0076] Blend polyetheretherketone and 40% carbon fiber at 400°C according to the ingredients and proportions in Example 1, and keep the shear rate at 150-250s -1 , to obtain the first blend; then at 350 ° C, the first blend, polyphenylene sulfide and the remaining 60% carbon fiber were blended according to the ingredients and proportions of Example 1, and the shear rate was maintained at 80 ~140s -1 , High thermal conductivity polyether ether ketone material. Then it was molded at 350°C into samples required for tensile and impact tests, and various performance tests were performed. The results are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com