Probiotic fermented rose residue product and preparation thereof

A technology of rose dregs and probiotics, applied in the field of food processing, can solve problems such as few reports on applied research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

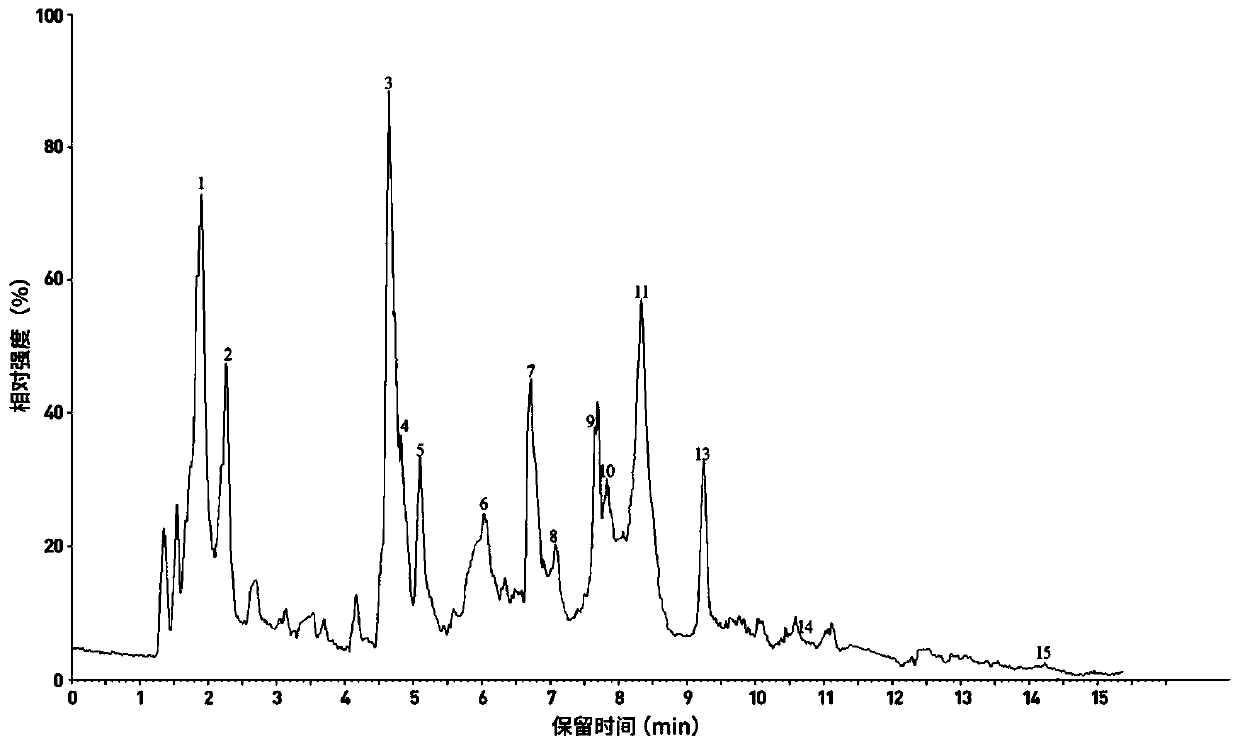

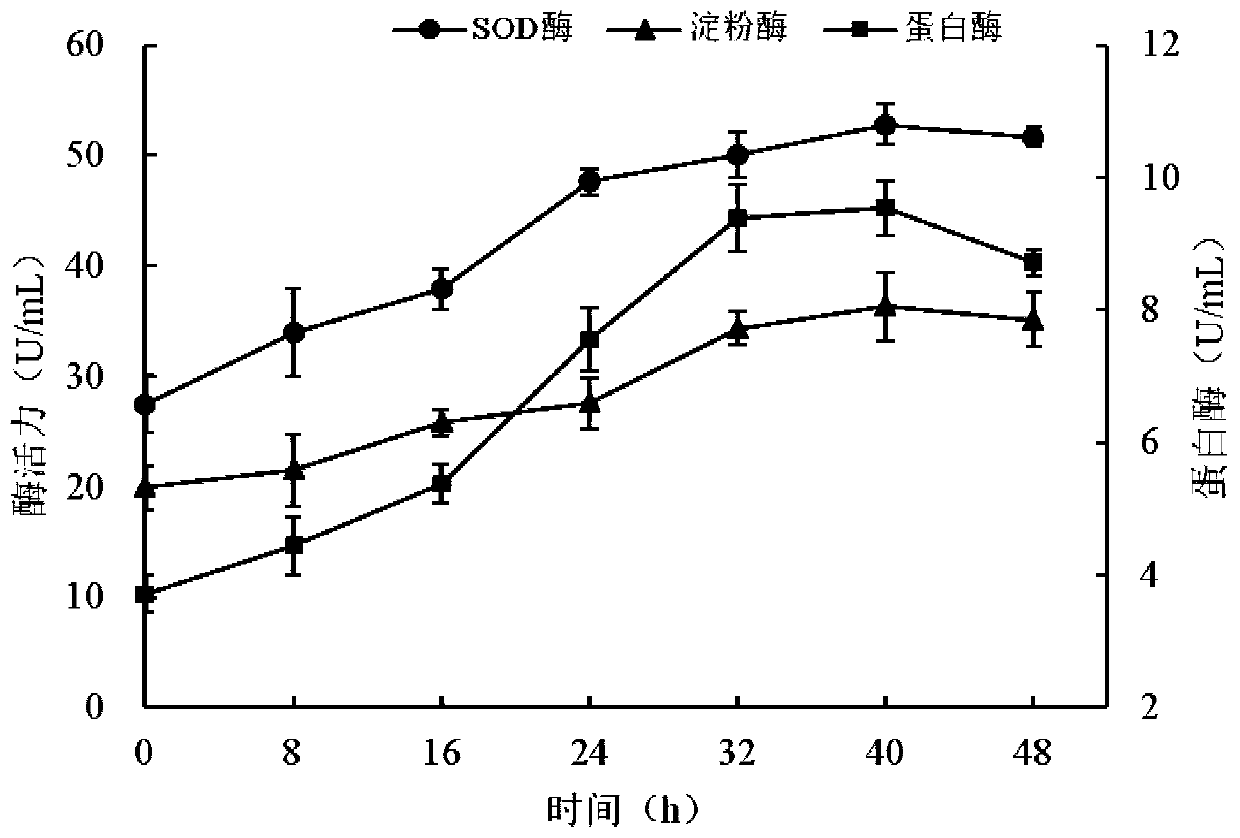

[0049] Embodiment 1 A kind of probiotic compound fermentation rose residue product

[0050] The present invention provides a probiotic compound fermented rose residue product, the preparation method of which is as follows:

[0051] (1) Preparation of rose dregs fermentation substrate: take the remaining rose dregs after essential oil extraction and dry them, pulverize them with a pulverizer and pass through a 100-mesh sieve to form a solution with a concentration of 1g / L, and mix them thoroughly. Sterilize at 121°C for 15 minutes to prepare rose residue fermentation substrate;

[0052] (2) Composite fermentation: insert 1% (V:V) Lactobacillus plantarum fermentation broth and 1% (V:V) Bacillus natto fermentation broth into the rose dregs fermentation substrate, 38°C, 110rpm, Fermentation 40h;

[0053] The preparation method of the Lactobacillus plantarum fermentation liquid is as follows: After the Lactobacillus plantarum is activated, it is cultured at 37° C. for 14 hours in...

Embodiment 2

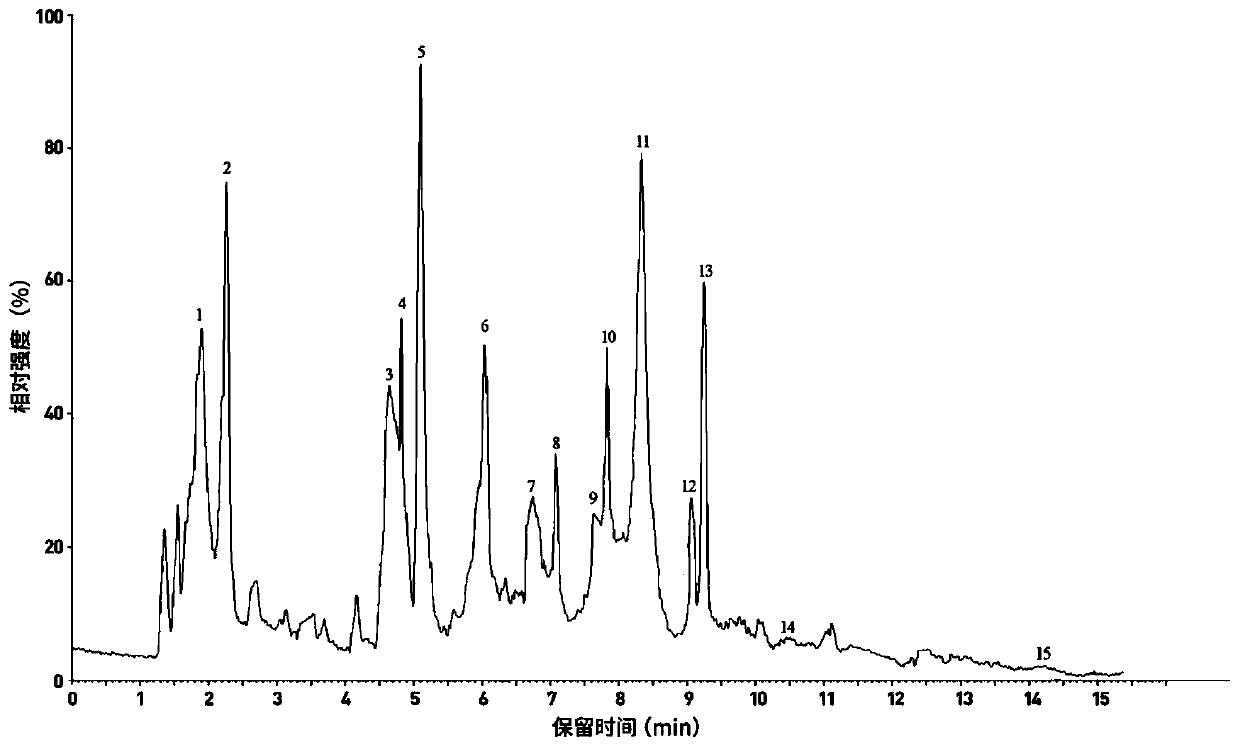

[0073] Embodiment 2 A kind of probiotic compound fermentation rose residue product

[0074] The present invention provides a probiotic compound fermented rose residue product, the preparation method of which is as follows:

[0075] (1) Preparation of rose dregs fermentation substrate: take the remaining rose dregs after essential oil extraction and dry them, crush them with a pulverizer and pass through a 100-mesh sieve, configure a solution with a concentration of 0.8g / L, and mix them thoroughly , sterilized at 121°C for 15 minutes to prepare the rose residue fermentation substrate;

[0076] (2) Composite fermentation: insert 0.5% (V:V) Lactobacillus plantarum fermentation broth and 0.5% (V:V) Bacillus natto fermentation broth into the rose residue fermentation substrate, 35°C, 100rpm, Ferment for 35 hours;

[0077] The preparation method of the Lactobacillus plantarum fermentation liquid is as follows: After the Lactobacillus plantarum is activated, it is cultured at 37° C...

Embodiment 3

[0082] Embodiment 3 A kind of probiotic compound fermentation rose residue product

[0083] The present invention provides a probiotic compound fermented rose residue product, the preparation method of which is as follows:

[0084] (1) Preparation of rose dregs fermentation substrate: take the remaining rose dregs after essential oil extraction and dry them, use a pulverizer to crush them, pass through a 100-mesh sieve, prepare a solution with a concentration of 1.2g / L, and mix them thoroughly , sterilized at 121°C for 15 minutes to prepare the rose residue fermentation substrate;

[0085] (2) Composite fermentation: insert 2% (V:V) Lactobacillus plantarum fermentation broth and 2% (V:V) Bacillus natto fermentation broth into the rose dregs fermentation substrate, 40°C, 150rpm, Ferment for 45h;

[0086] The preparation method of the Lactobacillus plantarum fermentation liquid is as follows: After the Lactobacillus plantarum is activated, it is cultured at 37° C. for 16 hours i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com