Printing dying shaping machine waste gas recovery and treatment system

A waste gas recovery and treatment system technology, applied to chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of high-voltage electrostatic device damage, cleaning, short life, etc., to prolong service life, improve work efficiency, The effect of improving the removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

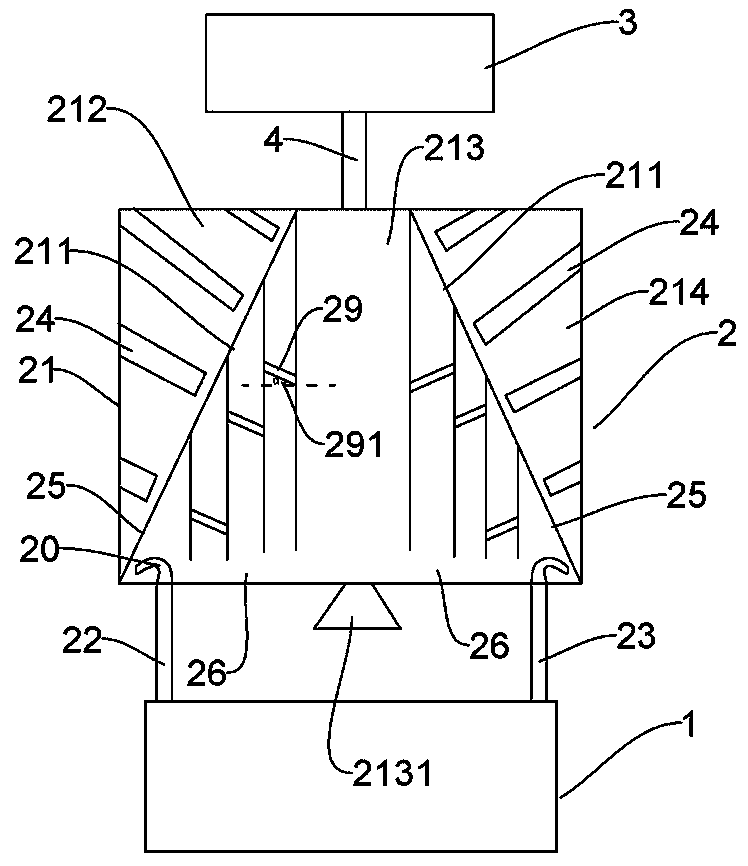

[0024] Such as figure 1 The exhaust gas recovery and treatment system of a printing and dyeing setting machine includes a waste heat recovery device 1 , a purification treatment device 2 and an electrostatic treatment device 3 .

[0025] One end of the waste heat recovery device 1 is connected to the waste gas outlet of the sizing machine, and the other end of the waste heat recovery device 1 is connected to the purification device 2, and the purification device 2 includes a housing 21 communicated with the waste heat recovery device 1 , the housing 21 is provided with two first partitions 211 to divide the housing 21 into a first nozzle area 212, a spray area 213 and a second nozzle area 214 in turn, and the bottom of the spray area 213 is two The upper end of the spray area 213 communicates with the electrostatic treatment device 3 through the third communication pipe 4. The first Both the nozzle area 212 and the second nozzle area 214 are provided with a plurality of nozzl...

Embodiment 2

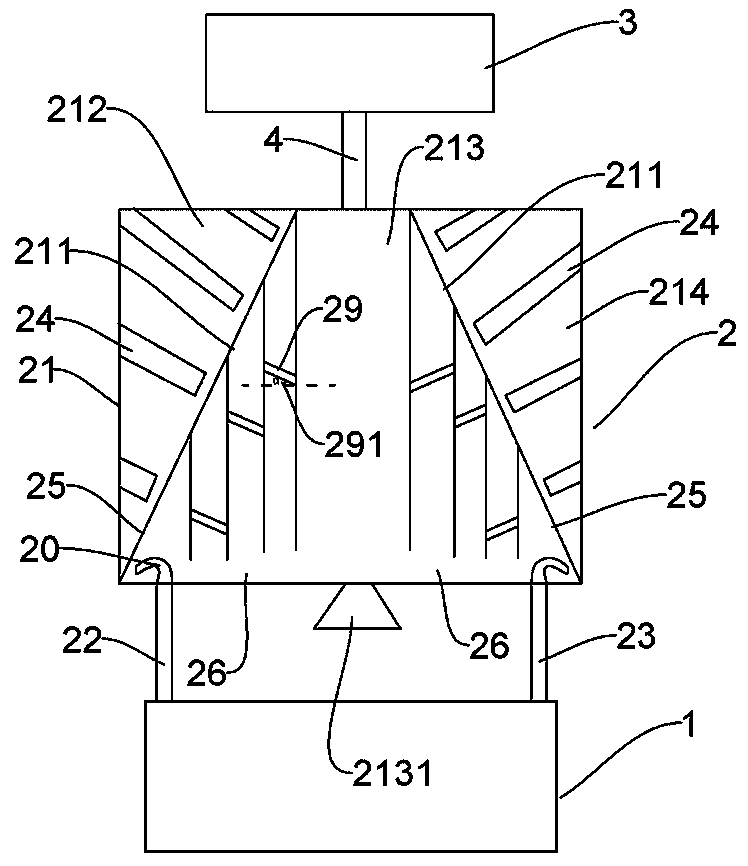

[0029] Such as figure 2 The exhaust gas recovery and treatment system of a printing and dyeing setting machine includes a waste heat recovery device 1 , a purification treatment device 2 and an electrostatic treatment device 3 . More preferably on the basis of embodiment 1:

[0030] The distance between the lower end of the second partition 25 and the bottom of the spraying area 213 decreases gradually from close to the corresponding first partition 211 to away from the corresponding first partition 211 , the first A partition 211 is provided with a drain plate 27 connected to the bottom of the spray area 213, the channel 26 is located between the drain plate 27 and the second partition 25, the first communication pipe 22 and the second The second communication pipe 23 communicates with a side of the flow guide plate 27 close to the corresponding first partition 211 . The setting of the diversion plate can let the water go out from the water outlet quickly, avoiding its acc...

Embodiment 3

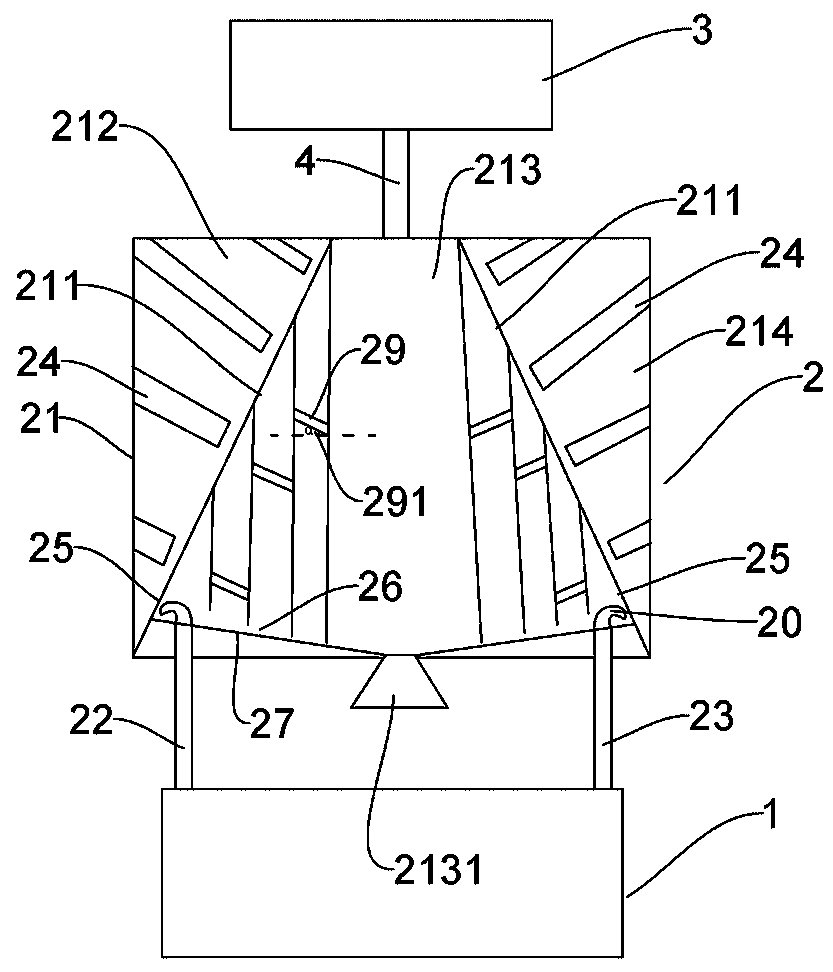

[0033] Such as image 3 The exhaust gas recovery and treatment system of a printing and dyeing setting machine includes a waste heat recovery device 1 , a purification treatment device 2 and an electrostatic treatment device 3 . The difference from Example 2 is:

[0034] The water outlet 2131 communicates with the junction of the two diversion plates 27 .

[0035] The connecting pipe 29 is provided with a plurality of third through holes. The exhaust gas can also be sprayed to a certain extent through the third through hole, which can more effectively reduce the amount of soot in the exhaust gas.

[0036] And in this embodiment, the angle α is selected as 45°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com