Ash melting compound fluxing agent and ash melting treatment method

A technology of flux and slag, which is applied in chemical instruments and methods, removal of solid waste, glass furnace equipment, etc., can solve problems such as difficulty in efficient, harmless and resourceful treatment of ash and slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

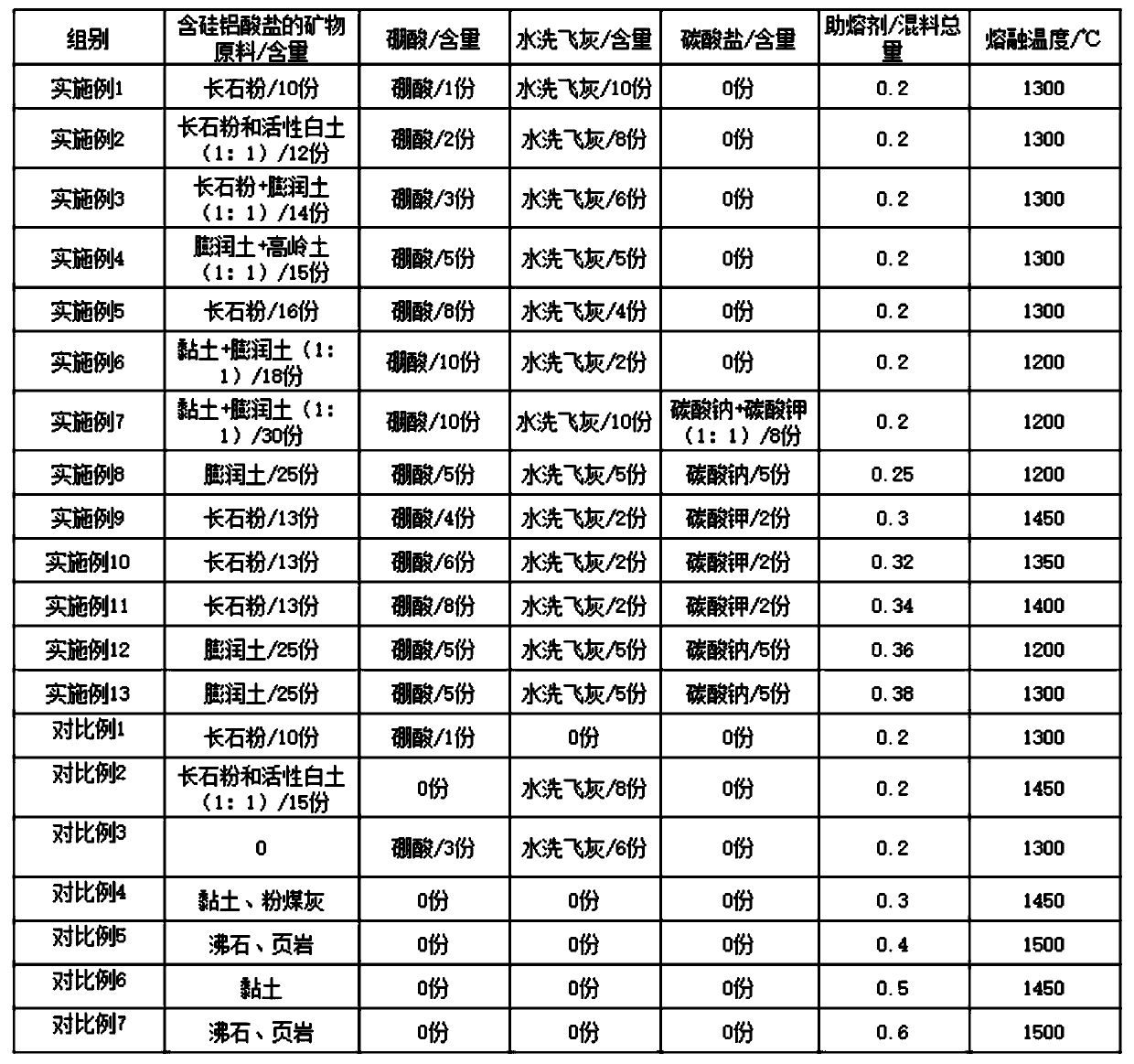

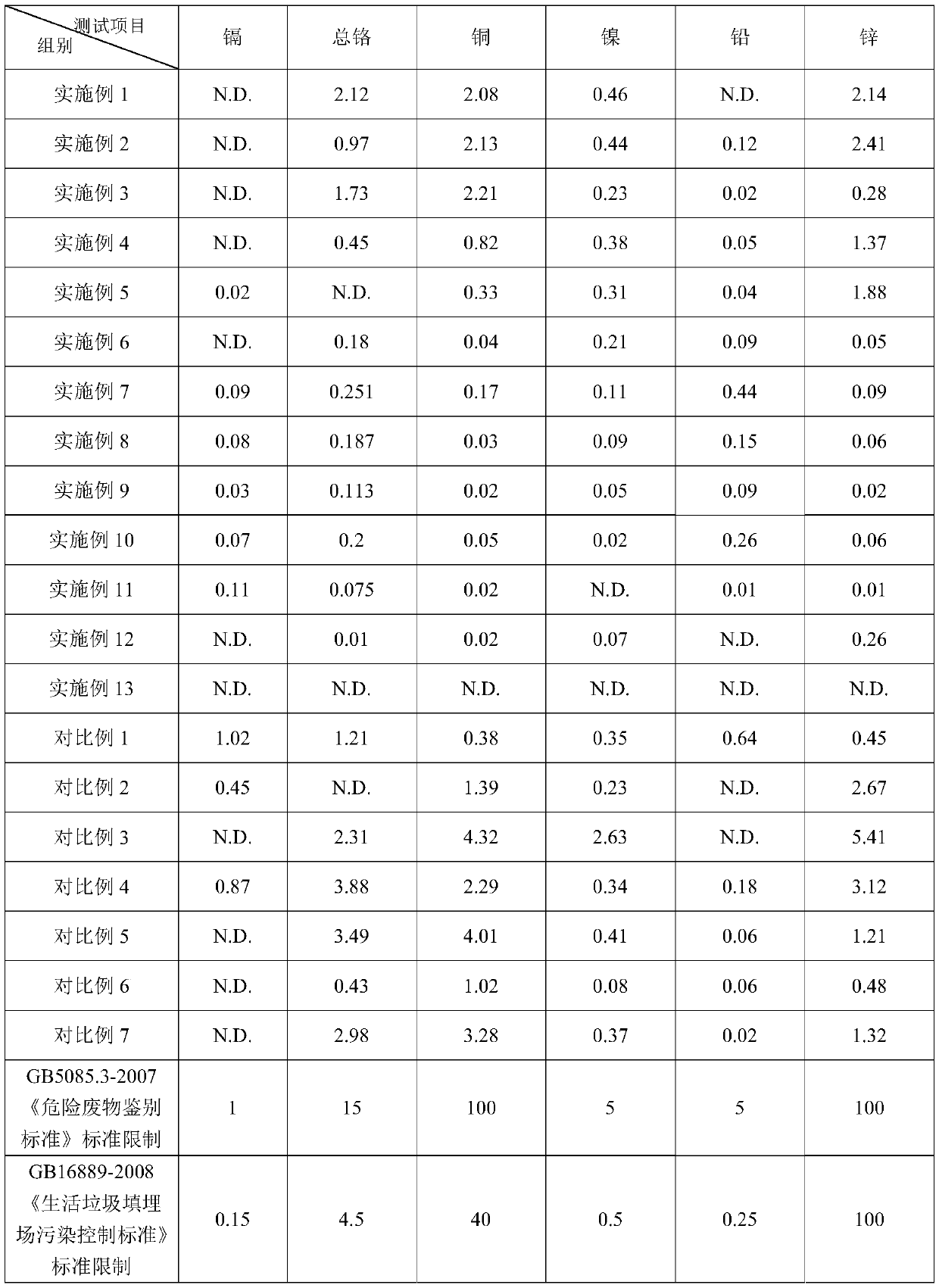

Examples

Embodiment 1

[0025] A composite flux for melting ash and slag comprises, in parts by weight, 10 parts of mineral raw materials containing aluminosilicate, 1 part of boric acid and 10 parts of washed fly ash. Among them, the aluminosilicate-containing mineral is bentonite.

[0026] The method for melting the ash and slag by using the ash and slag melting compound flux agent comprises the following steps:

[0027] (1) Provide ash and slag samples and the above-mentioned ash and slag melting composite flux, the ash and slag melting composite flux accounts for 20% of the total amount of the mixture;

[0028] (2) Fully stir the ash slag sample and the ash slag fusion composite flux to form a mixture, and perform ball milling treatment, and then place it in an oven at 60°C for drying;

[0029] (3) Put the mixed material into a plasma melting furnace for melting treatment, and heat at 1300° C. for 1 hour;

[0030] (4) After the mixture is completely melted, it is cooled in water to obtain glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com