Processing method of waste water generated in printing ink plastic package container cleaning

A technology for plastic packaging and wastewater treatment, applied in water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. Reduced disposal cost, easy removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

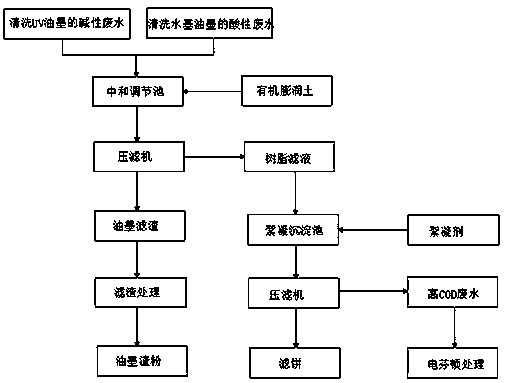

[0028] A wastewater treatment method for cleaning ink plastic packaging containers, comprising the following steps:

[0029] 1) Take the material, heat soak and clean the UV ink plastic packaging tank to obtain alkaline wastewater, and heat soak and clean the water-based ink plastic packaging barrel to obtain acid wastewater;

[0030] 2) Mix, inject the above alkaline wastewater and acid wastewater into the neutralization reaction tank and mix until uniform;

[0031] 3) Acid precipitation and precipitation, add 10% H to the mixed wastewater 2 SO 4 dilute acid, adjust the pH to 3, then add bentonite, stir and react to obtain a solid-liquid mixture;

[0032] 4) Press filtration, pump the obtained solid-liquid mixture into a filter press for solid-liquid separation, and obtain filter residue and primary filtrate respectively, wherein the filter residue is filter residue containing ink pigment, and the primary filtrate is resin filtrate containing ink ;

[0033] 5) filter resi...

Embodiment 2

[0041] A wastewater treatment method for cleaning ink plastic packaging containers, comprising the following steps:

[0042] 1) Take the material, heat soak and clean the UV ink plastic packaging tank to obtain alkaline wastewater, and heat soak and clean the water-based ink plastic packaging barrel to obtain acid wastewater;

[0043] 2) Mix, inject the above alkaline wastewater and acid wastewater into the neutralization reaction tank and mix until uniform;

[0044] 3) Acid precipitation, adding hydrochloric acid to the mixed wastewater, adjusting the pH to 3, then adding bentonite, stirring and reacting to obtain a solid-liquid mixture;

[0045] 4) Press filtration, pump the obtained solid-liquid mixture into a filter press for solid-liquid separation, and obtain filter residue and primary filtrate respectively, wherein the filter residue is filter residue containing ink pigment, and the primary filtrate is contain ink resin filtrate;

[0046] 5) filter residue treatment, d...

Embodiment 3

[0052] A wastewater treatment method for cleaning ink plastic packaging containers, comprising the following steps:

[0053] 1) Take the material, heat soak and clean the UV ink plastic packaging tank to obtain alkaline wastewater, and heat soak and clean the water-based ink plastic packaging barrel to obtain acid wastewater;

[0054] 2) Mix, inject the above alkaline wastewater and acid wastewater into the neutralization reaction tank and mix until uniform;

[0055] 3) Acid precipitation and precipitation, add 10% H to the mixed wastewater 2 SO 4 dilute acid, adjust the pH to 4, then add bentonite, stir and react to obtain a solid-liquid mixture;

[0056] 4) Press filtration, pump the obtained solid-liquid mixture into a filter press for solid-liquid separation, and obtain filter residue and primary filtrate respectively, wherein the filter residue is filter residue containing ink pigment, and the primary filtrate is contain ink resin filtrate;

[0057] 5) filter residue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com