Electric heating waste gas treatment device with double-layer sleeve structure

An exhaust gas treatment device and a double-layer casing technology are applied in the direction of exhaust devices, noise reduction devices, engine components, etc., which can solve problems such as potential safety hazards, damage to electrical insulation ceramics of heating electrical components, and unfavorable maintenance in the later period, so as to increase the use of Longevity, reduce serious local aging problems, and avoid the effects of core damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

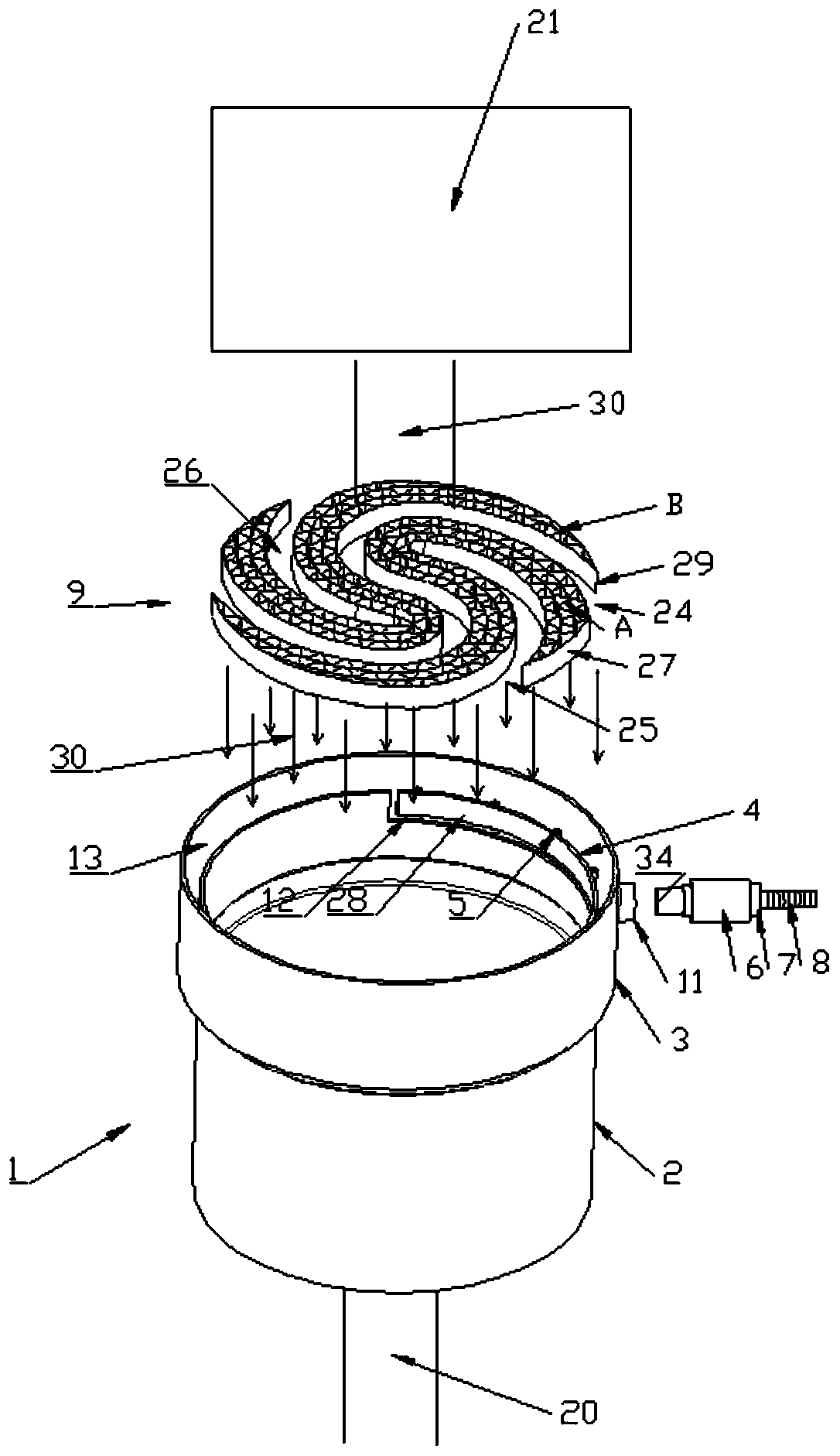

[0032] see figure 1 with 2, shows the electric heating exhaust gas treatment device with double-layer casing structure of the present invention.

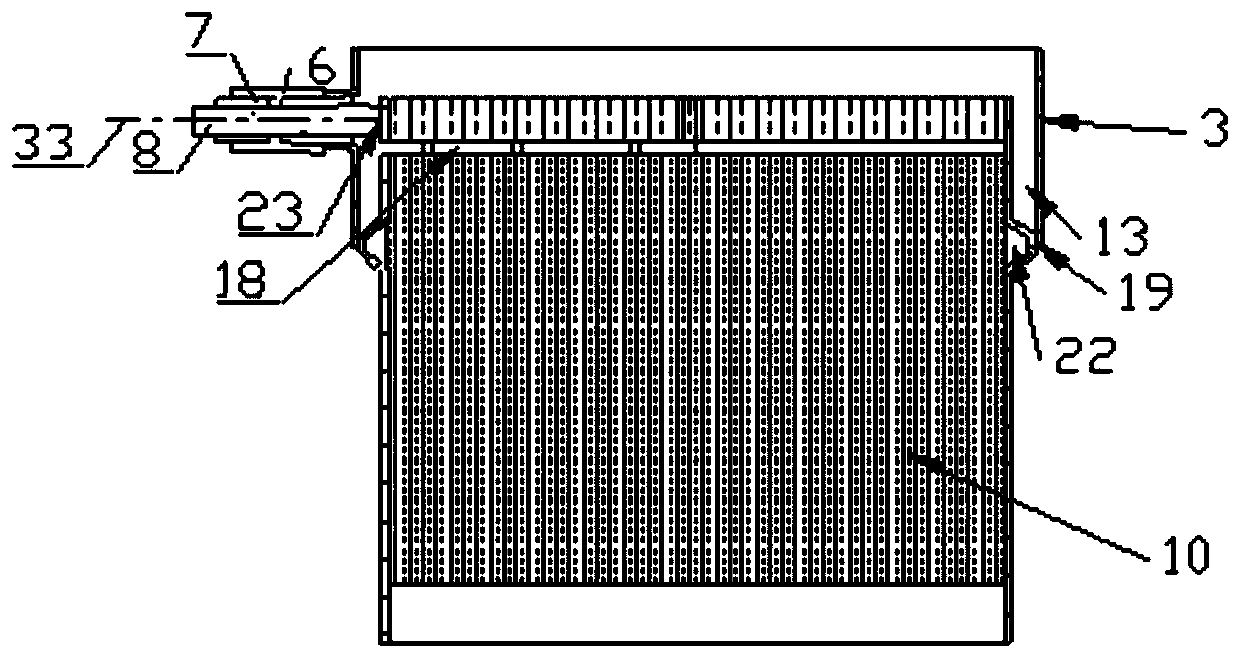

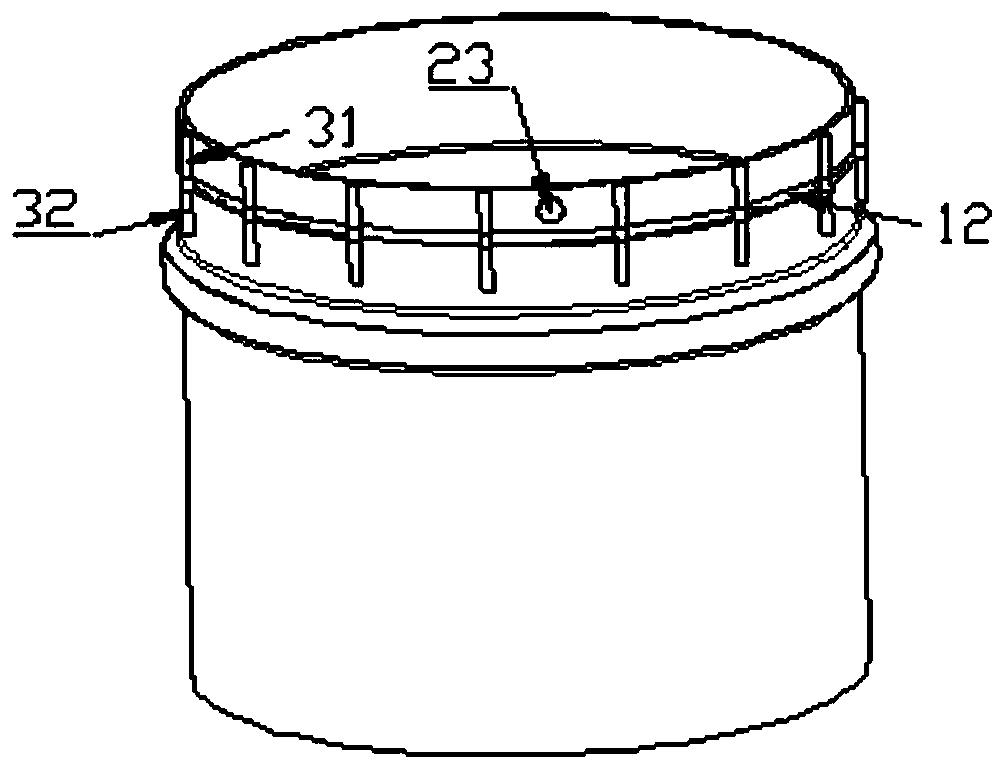

[0033] The electric heating waste gas treatment device 1 with a double-layer sleeve structure is used to purify the exhaust gas of the internal gas 21, which is arranged in the exhaust system 20 of the internal combustion engine 21, and includes an inner sleeve 2, an outer sleeve 3 and a metal catalyst Carrier 10, a metal catalyst carrier 10 is provided in the inner casing, the upper outer edge of the inner casing 2 is provided with a radially outwardly protruding trapezoidal reinforcing rib 19, and the outer diameter of the trapezoidal reinforcing rib 19 is Equal and the outer side is connected to the inner wall of the lower end of the outer casing 3, so that a double-layer casing gap 13 is formed between the outer layer casing 3 and the inner layer casing 2, and the double-layer casing gap 13 is preferably greater than or equal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com