Printed circuit board and test fixture

A technology for printed circuit boards and backplanes, used in printed circuits, printed circuit manufacturing, printed circuit components, etc., can solve the problems of discontinuous impedance, increased test times, and low test efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The embodiment of the present application provides a printed circuit board, which will be described below.

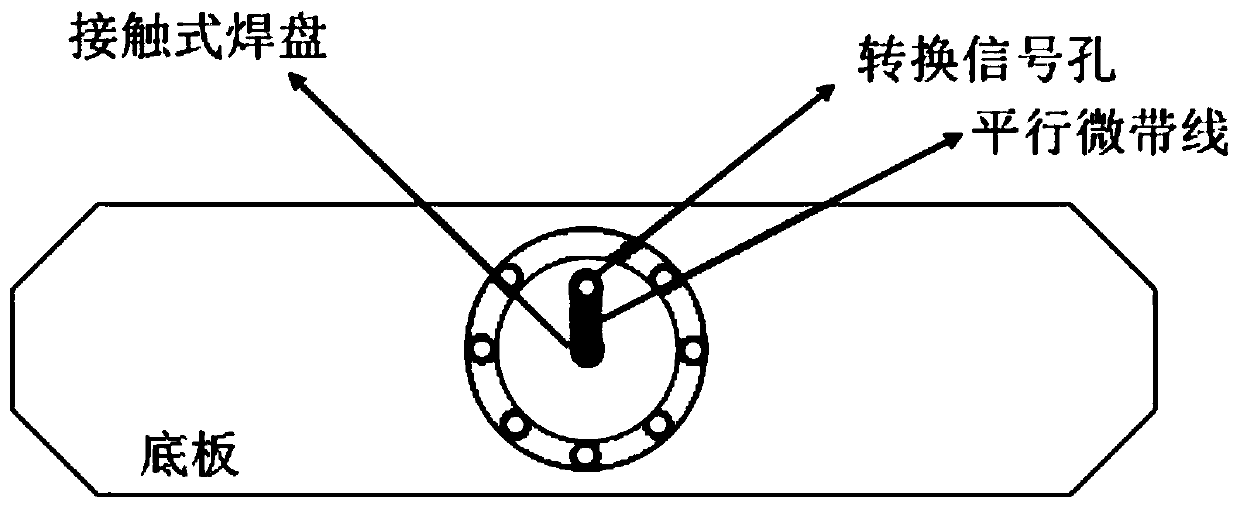

[0020] figure 2 It shows a top plan structural schematic view of the contact pad of the printed circuit board in the embodiment of the present application.

[0021] Example of this application figure 2 A single connection point is taken as an example. As shown in the figure, the printed circuit board includes: a base plate and one or more connection points, the base plate includes multiple layers, and the one or more connection points are located at the The outermost layer of the bottom plate, each connection point includes a contact pad and a conversion signal hole; the contact pad is connected to the conversion signal hole through a parallel microstrip line; the conversion signal hole is used to connect the other layers of the bottom plate.

[0022] During specific implementation, the printed circuit board in the embodiment of the present application may i...

Embodiment 2

[0061] Based on the same inventive concept, an embodiment of the present application provides a test fixture.

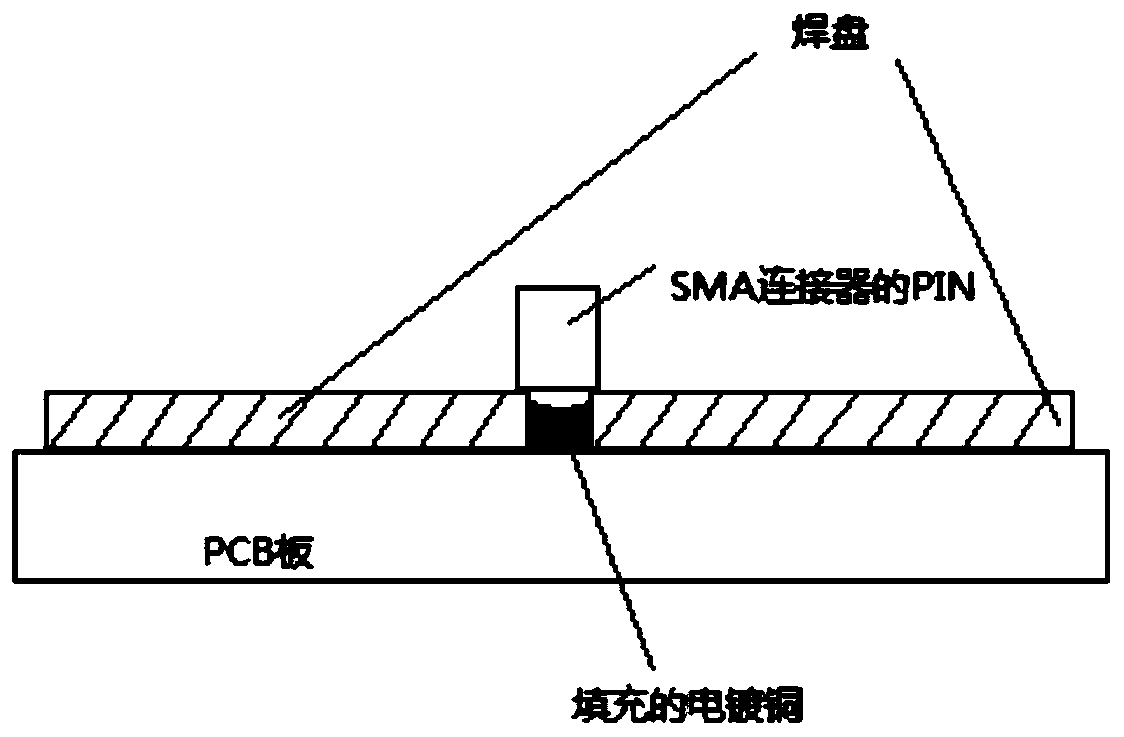

[0062] Figure 4 A schematic structural diagram of the test fixture in the embodiment of the present application is shown.

[0063] As shown in the figure, the test fixture includes: the printed circuit board as described in Embodiment 1, and an SMA connector, the PIN of the SMA connector is bonded to the contact pad, and the SMA connector The other end is connected with a transmission line, and the transmission line is used for connecting the device under test.

[0064] During specific implementation, the device under test may be a device component such as a connector under test, an oscilloscope, and the like.

[0065] The SMA connector is solder-free, and can be directly fixed and assembled with the printed circuit board by screws. The contact pad is located at the center of the SMA connector to ensure precise alignment between the contact pad and the PIN of the...

Embodiment 3

[0078] The following embodiment of the present application will be described with a specific example.

[0079] The bottom plate of the PCB is provided with 3 connection points A, B, C, and each connection point includes an SMA contact pad and a conversion signal hole; the SMA contact pad is connected to the conversion via a parallel microstrip line. The signal hole is connected; the conversion signal hole is used to connect different layers of the bottom board.

[0080] The radius of the SMA contact pad is 0.2mm-0.4mm, the size of the conversion signal hole is 0.5mm, and the distance from the conversion signal hole to the center of the SMA contact pad is 0.5mm-2mm, The impedance of the conversion signal hole is 50 ohms. The line width of the parallel microstrip line can be calculated according to the impedance, and the impedance of the parallel microstrip line is 50 ohms.

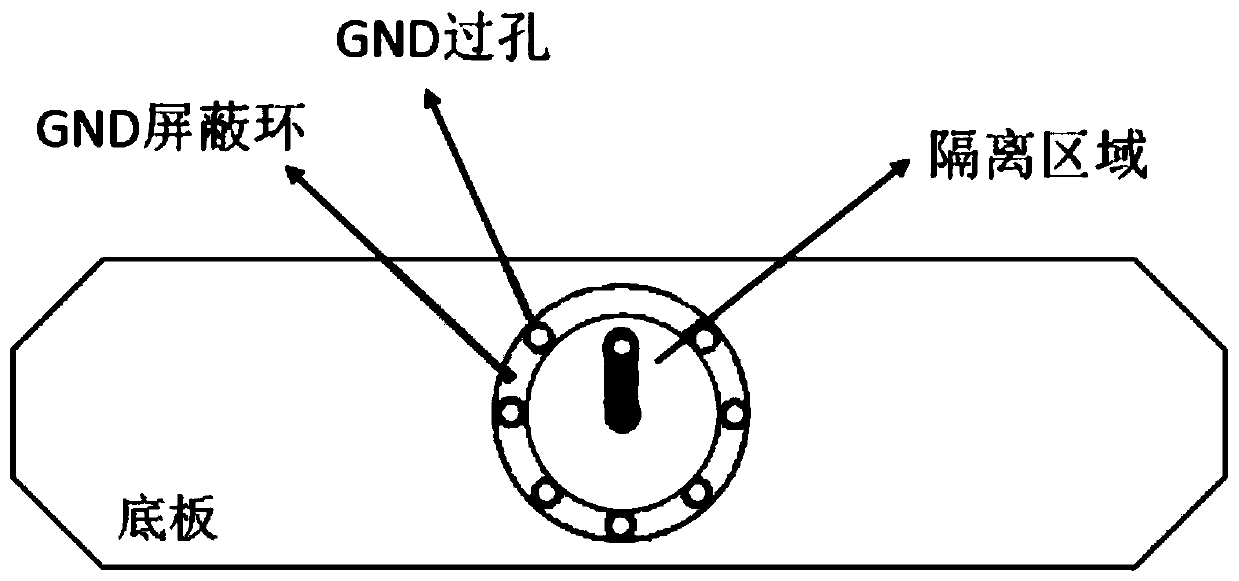

[0081] A GND shielding ring is arranged around the outside of the SMA contact pad and the conversion s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com