Polymer grinding aid for cement and preparation method of grinding aid

A cement grinding aid and polymer technology are applied in the field of polymer cement grinding aid and its preparation to achieve the effects of increasing output, improving grinding aid efficiency, and being non-radioactive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

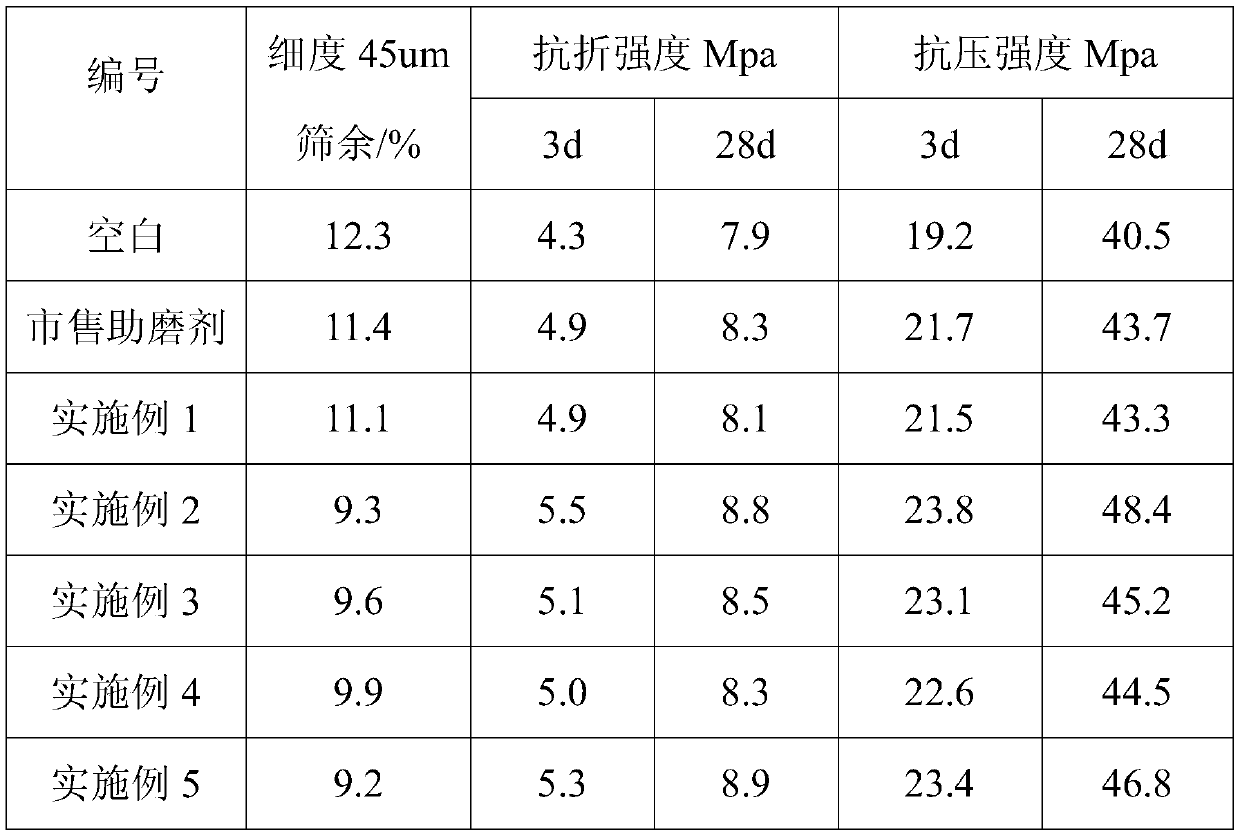

Examples

Embodiment 1

[0020] A kind of polymer cement grinding aid, its raw material is composed of: Tetrahydroxyethylethylenediamine 4%, dispersant 0.5%, crude glycerin 15%, sugar 3%, sodium thiosulfate 7%, polyvinyl alcohol 0.3% , tetrahydroxypropyl ethylenediamine 3%, the balance is water, the total amount is 100%;

[0021] The percentages are mass percentages, according to the formula ratio, tetrahydroxyethylethylenediamine, dispersant, crude glycerin, sugar, sodium thiosulfate, polyvinyl alcohol and tetrahydroxypropylethylenediamine are dissolved in water, mixed Uniform, that is, product 1.

Embodiment 2

[0023] A kind of polymer cement grinding aid, its raw material is composed of: Tetrahydroxyethylethylenediamine 9%, dispersant 0.8%, crude glycerin 27%, sugar 10%, sodium thiosulfate 15%, polyvinyl alcohol 0.5% , Tetrahydroxypropylethylenediamine 8%, the balance is water, the total amount is 100%;

[0024] The percentages are all mass percentages. According to the formula ratio, dissolve tetrahydroxyethylethylenediamine, dispersant, crude glycerin, sugar, sodium thiosulfate, polyvinyl alcohol and tetrahydroxypropylethylenediamine in water, and mix well , namely, product 2.

Embodiment 3

[0026] A kind of polymer cement grinding aid, its raw material is composed of: Tetrahydroxyethylethylenediamine 7%, dispersant 0.7%, crude glycerin 21%, sugar 6%, sodium thiosulfate 13%, polyvinyl alcohol 0.4% , tetrahydroxypropyl ethylenediamine 5%, the balance is water, the total amount is 100%;

[0027] The percentages are all mass percentages. According to the formula ratio, dissolve tetrahydroxyethylethylenediamine, dispersant, crude glycerin, sugar, sodium thiosulfate, polyvinyl alcohol and tetrahydroxypropylethylenediamine in water, and mix well , namely, product 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com