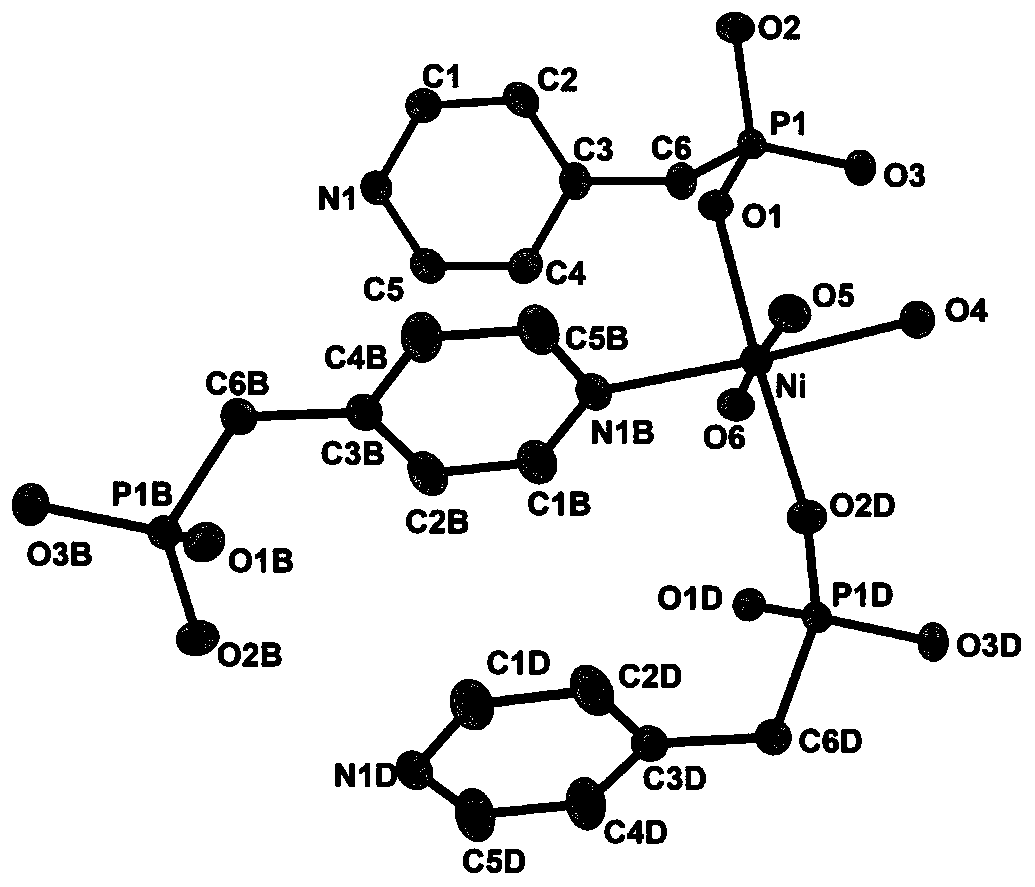

Nickel pyridine methylene phosphonate coordination polymer as well as preparation method and application thereof

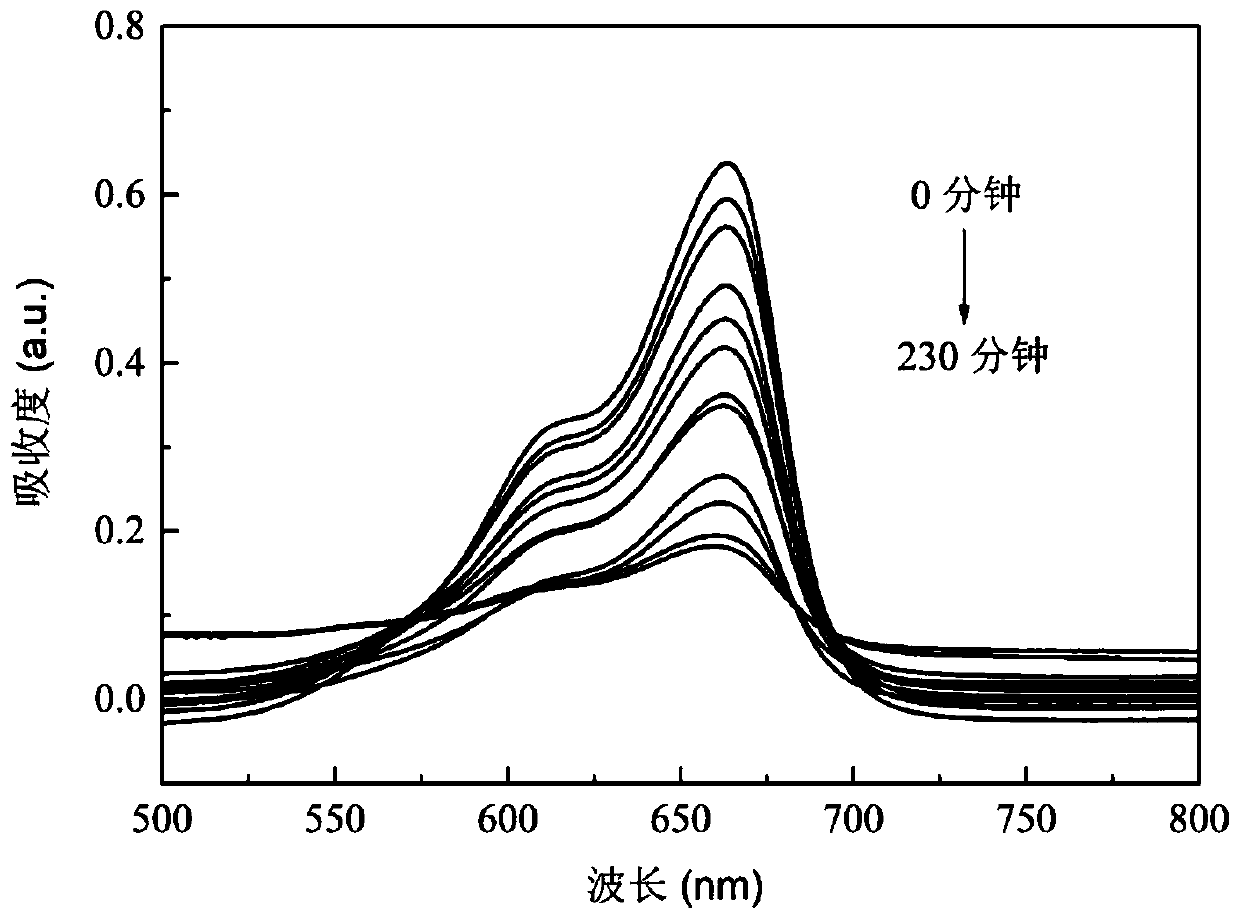

A technology of pyridylmethylene phosphonic acid and coordination polymers, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem that photocatalysts cannot be recycled and reused and other issues, to achieve the effect of high stability and high photochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the nickel pyridyl methylene phosphonate coordination polymer of the present embodiment is as follows:

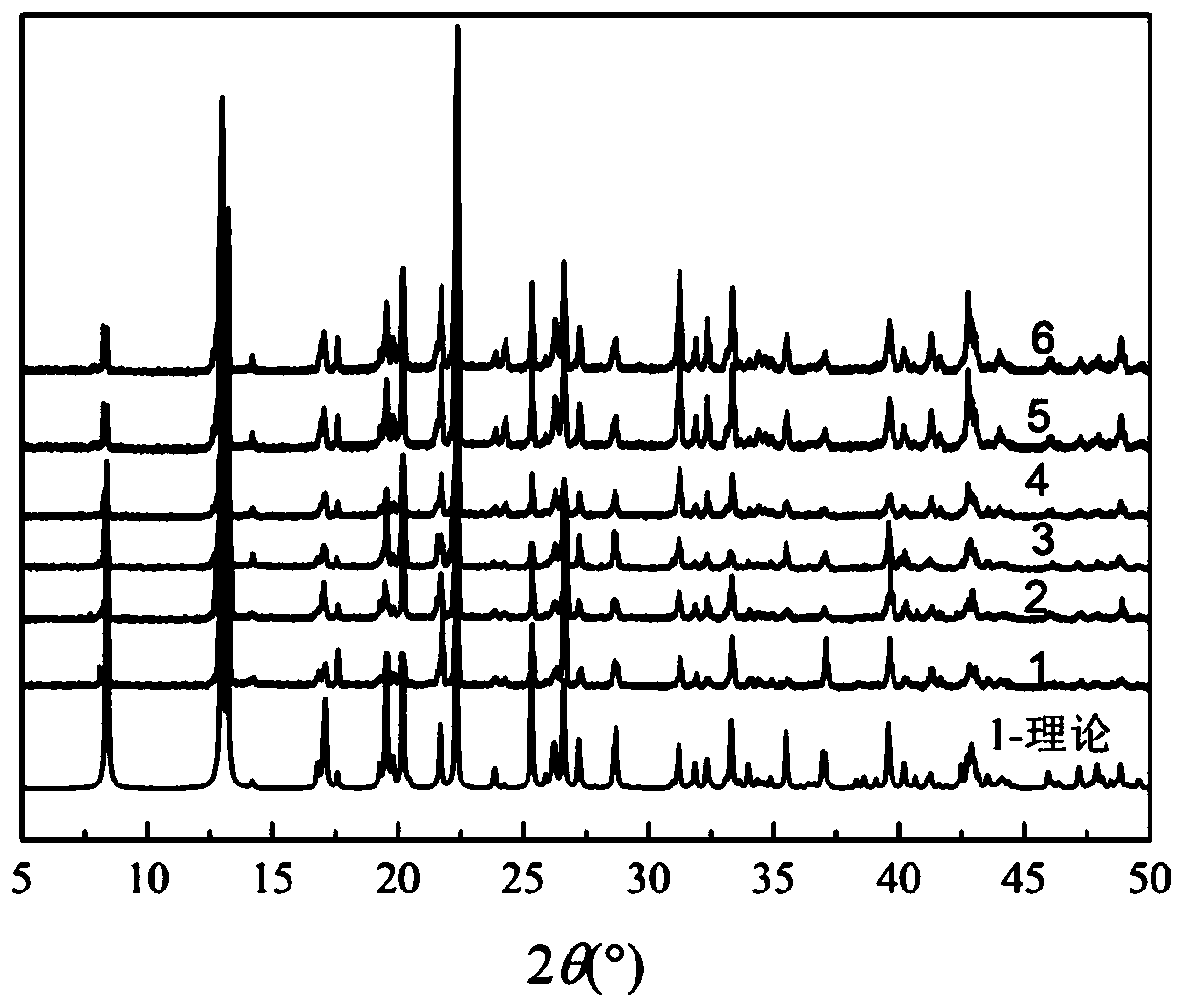

[0029] Weigh 4-pyridinemethylenephosphonic acid (0.1mmol, 0.0173g) and nickel acetate (0.1mmol, 0.0249g), dissolve it in 8mL of distilled water, stir and mix evenly with ultrasonic, and measure the pH of the mixture with a pH meter to be 5.3. Put the mixed solution in a high-pressure hydrothermal kettle lined with polytetrafluoroethylene, and place the hydrothermal kettle in a closed oven at 120°C for heating reaction. After the reaction for 80 hours, naturally cool to room temperature, filter, wash, and dry to obtain Target product, marked 1. Yield 52.8%. Product 1 was characterized by PXRD, such as figure 2 As shown, the structure of the product of this example is consistent with the simulation results of theoretical values, indicating that the product is very pure.

Embodiment 2

[0031] The preparation method of the nickel pyridyl methylene phosphonate coordination polymer of the present embodiment is as follows:

[0032] Weigh 4-pyridylmethylenephosphonic acid (0.1mmol, 0.0173g) and nickel acetate (0.1mmol, 0.0249g), dissolve it in 6mL of distilled water, stir and mix evenly with ultrasonic, and measure the pH value of the mixture with a pH meter to be 5.3. The mixed solution was placed in a high-pressure hydrothermal kettle lined with polytetrafluoroethylene, and the hydrothermal kettle was placed in a closed oven at 120°C for heating reaction. After the reaction was completed for 72 hours, it was naturally cooled to room temperature, filtered, washed, and dried to obtain Target product, marked 2. Yield 50.7%. Product 2 was characterized by PXRD, such as figure 2 Shown, PXRD test result shows, the product of the present embodiment is identical with the product of embodiment 1.

Embodiment 3

[0034] The preparation method of the nickel pyridyl methylene phosphonate coordination polymer of the present embodiment is as follows:

[0035] Weigh 4-pyridinemethylenephosphonic acid (0.1mmol, 0.0173g) and nickel acetate (0.1mmol, 0.0249g), dissolve it in 10mL of distilled water, and mix well by ultrasonic stirring. The mixed solution was placed in a high-pressure hydrothermal kettle lined with polytetrafluoroethylene, and the hydrothermal kettle was placed in a closed oven at 130°C for heating reaction. After the reaction was completed for 72 hours, it was naturally cooled to room temperature, filtered, washed, and dried to obtain Target product, marked 3. Yield 45%. Product 3 was characterized by PXRD, such as figure 2 Shown, PXRD test result shows, the product of the present embodiment is identical with the product of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com